Литье по выплавляемым моделям Производитель металлических деталей Литье — это универсальная технология...

Индивидуальные решения по литью металла для отраслей по всему миру

HDC — литейный завод, сертифицированный по стандарту ISO и обслуживающий более 50 стран с 2009 года. Получите бесплатную смету в течение 24 часов

• Качество, сертифицированное по стандарту ISO 9001

• Быстрая доставка по всему миру

• Комплексные решения

Наши услуги по кастингу

Мы предлагаем широкий спектр вариантов литья для удовлетворения различных потребностей в литье металлов.

Инвестиционное литье

Процесс точного литья, который идеально подходит для средних и мелких деталей весом от 10 г до 50 кг.

- Сверхтонкостенные отливки от 0,5 мм

- Высокая точность поверхности

- Возможность литья более 300 видов сплавов

Учить больше

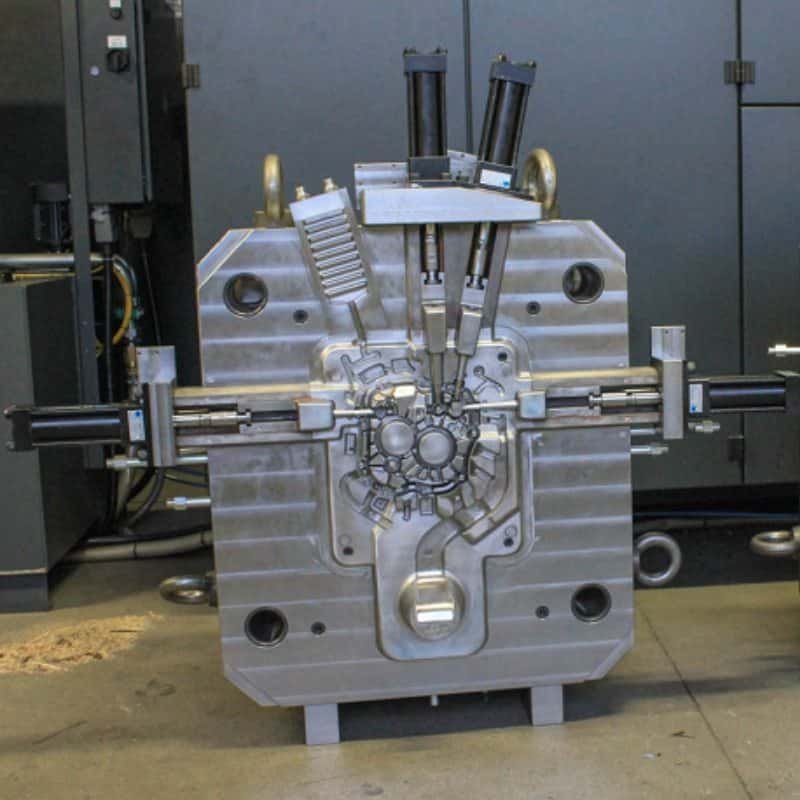

Литье под давлением

Самые точные и высокоэффективные методы литья, широко используемые в электронной и автомобильной промышленности.

- Высокоскоростное литье сплава цинка, магния и алюминия

- Доступна сложная структура

- Экономически эффективно для массового производства

Учить больше

Литье в песчаные формы

Гибкий метод литья для прототипов и мелкосерийного производства, идеально подходит для литья крупных деталей.

- Низкая стоимость пресс-формы

- 1600°C+ жаропрочное литье из суперсплава

- Возможность литья металлических деталей весом от 0,5 кг до 20 тонн.

Учить больше

Материалы и обработка поверхности

Широкий выбор материалов и вариантов отделки для наших услуг по литью металла на заказ

Литейные материалы

Углеродистая сталь

1010, 1020, 1045, 1060, 1080

Суперсплав

Инконель 625, 718, Хастеллой X

Алюминиевый сплав

А357, А380, А443, А514

Магниевый сплав

AZ91D, AM50A, AM60B

Обработка поверхности

Обработанный

Обработка на станке с ЧПУ для обеспечения жестких допусков

Пескоструйная обработка/обработка дробью

Удалить заусенцы и дефекты поверхности

Термически обработанный

Покрытие

Порошковое покрытие

Превосходная долговечность, экологичность

Комплексные решения для литья

Впервые покупаете услугу литья онлайн? Не волнуйтесь! HDC предлагает вам комплексную услугу литья металла от проектирования, производства до доставки.

Отрасли, в которых мы работаем

Поставка литых компонентов для различных секторов с использованием специализированного отраслевого опыта

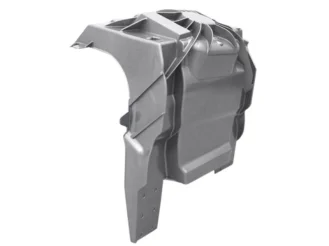

Автомобильный

Блоки двигателей, корпуса трансмиссии, компоненты тормозной системы, детали подвески

Машины

Корпуса насосов, корпуса клапанов, корпуса редукторов, промышленное оборудование

Строительство

Детали тяжелого оборудования, конструктивные элементы, детали экскаваторов

морской

Гребные винты, корпусные детали, компоненты двигателя, морское оборудование

Энергия

Компоненты турбин, трубопроводная арматура, детали для возобновляемых источников энергии

Электрический

Корпуса двигателей, компоненты трансформаторов, электрические корпуса

Гарантия качества точности

Наше стремление к совершенству лежит в основе всех аспектов нашей литейной деятельности и подтверждается международными сертификатами и передовыми системами качества.

Международные сертификаты:

✓ ISO 9001:2015 Система менеджмента качества

✓ ISO 14001:2015 Экологический менеджмент

✓ IATF 16949 Стандарт качества для автомобилей

Контроль качества

3D-сканирование (≤±0,05 мм), рентгеновское обнаружение дефектов, измерение КИМ

100% Инспекция

Каждая отливка проходит комплексную проверку качества

Квалификация поставщика

Строгий аудит поставщиков сырья гарантирует высокое качество материалов

Глобальные стандарты

Соответствие ASTM, DIN, JIS и другим международным стандартам

Почему стоит выбрать наш литейный завод

Более 10 лет безупречного литья, поставки превосходных компонентов по всему миру

Техническая экспертиза

- Команда передовых металлургических инженеров

- Современное литейное оборудование

- Непрерывная оптимизация процесса

- Возможность разработки новых сплавов

Производственная мощность

- Годовая мощность литья более 5000 тонн

- Гибкие размеры партий от прототипа до массового производства

- Доступны различные процессы литья

Глобальный охват

- Доставка и логистика по всему миру

- Многоязычная техническая поддержка

- Международные стандарты качества

Индивидуальные решения

- Разработка сплавов для конкретных применений

- Услуги по созданию прототипов и инструментов

- Консультации по оптимизации дизайна

- Полное управление цепочкой поставок

Процесс предоставления услуг кастинговых услуг на заказ

Следуйте простому процессу предоставления услуг по литью металла, гарантируя бесперебойную реализацию проекта

1. Цитата

Загрузите ваши чертежи или спецификации. Мы предоставим подробную смету в течение 24 часов.

2. Обзор проекта

Технический анализ ваших требований и рекомендации по оптимизации дизайна

3. Прототипирование

Производство образцов для утверждения перед началом полномасштабного производства

4. Производство

Массовое производство с постоянным контролем качества и обновлениями хода работ

5. Доставка

Окончательная проверка, упаковка и отслеживаемая по всему миру дистрибуция

Подробнее о HDC

Узнайте больше о компании HDC, включая наше оборудование и сертификаты, и обретите больше уверенности в сотрудничестве с нами.

| Оборудование | Технические характеристики | Количество |

| Машины для инъекций воска | – | 5 |

| Вакуумные плавильные печи | Грузоподъемность 50 кг, 100 кг | 2 |

| Среднечастотные индукционные печи | 250 кг (2 единицы), 100 кг (1 единица) | 3 |

| Печи для обжига оболочки | – | 2 |

| Печи для термической обработки | – | 2 |

| Дробеструйные машины | – | 5 |

| Пескоструйные машины | – | 2 |

| Спектрометр | SPECTRO Германия, 5-е поколение. Прямое считывание | 1 |

| Машина для испытания на растяжение | – | 1 |

| Система электроснабжения | Трансформаторы коробчатого типа 630 кВА | 2 |

Что такое кастинг

Литье — это процесс, при котором расплавленный металл заливается в форму, содержащую полость (форма полости соответствует форме желаемого изделия), при этом полость заполняется расплавленным металлом под действием силы тяжести или давления, а расплавленный металл охлаждается и затвердевает, образуя деталь.

Преимущества литья

- Разнообразный процесс литья: Более 10 типов литейных процессов, таких как литье в песчаные формы, литье по выплавляемым моделям, литье под давлением и т. д., предназначены для удовлетворения различных технологических потребностей.

- Материальная адаптивность: От железа, стали, алюминия до суперсплавов — можно отливать из любого распространенного металлического материала.

- Сложная геометрия достижима: Полые структуры, тонкостенные структуры и внутренние каналы. Сложная геометрия, которую невозможно обработать с помощью станка, может быть легко отлита.

- Низкая стоимость массового производства: Форма пригодна для повторного использования, что обеспечивает значительные экономические преимущества при крупномасштабном производстве.

Недостатки литья

- Более низкие механические свойства: Отливки имеют более крупное зерно, а прочность отливки ниже, чем у поковки из того же материала.

- Высокая начальная стоимость: Литье под давлением и литье по выплавляемым моделям требует изготовления точных форм, что может потребовать значительных первоначальных инвестиций.

- Внутренние дефекты: Хотя внутренние дефекты, такие как пористость, усадочная пористость и включения песка, можно уменьшить, контролируя скорость литья, скорость охлаждения и используя вакуумное литье, полностью избежать их все равно невозможно.

- Ограниченная точность размеров и качество поверхности

Виды литья

Сравнение характеристик, применяемых металлов и уровней допусков для распространенных методов литья.

| Процесс литья | Тип формы/шаблона | Подходящие металлы | Точность/Качество обработки поверхности | Скорость производства |

|---|---|---|---|---|

| Литье в песчаные формы | Форма для песка (одноразовая) | Почти все металлы (железо, сталь, алюминий и т. д.) | Низкий (CT11-14), грубый | Низкий-средний |

| Постоянное литье в форму | Металлическая форма (многоразовая) | Легкоплавкие сплавы (Al, Mg, Cu) | Средне-высокий (CT8-10), гладкий | Высокая |

| Литье под давлением | Металлическая форма + Высокое давление | Сплавы Al, Mg, Zn | Очень высокий (CT6-8), отличный | Очень высокий |

| Инвестиционное литье | Керамическая оболочка (одноразовая) | Все металлы (особенно суперсплавы) | Самый высокий (CT4-7), гладкий | Низкий |

| Литье по выплавляемым моделям | Сухой песок + пенный узор | Чугун, Сталь, Алюминий | Средне-высокий (CT6-9), гладкий | Средний-Высокий |

| Литье под низким давлением | Металлическая форма + низкое давление | В основном сплавы Al, Mg | Высокий (CT7-9), гладкий | Средний-Высокий |

| Центробежное литье | Вращающаяся металлическая/песчаная форма | Железо, Сталь, Медь, Алюминий | Хорошая внешняя поверхность, внутренняя обработана | Высокая |

Часто задаваемые вопросы

Получите ответы на часто задаваемые вопросы о нашей службе кастинга.

Просто отправьте нам ваши чертежи или спецификации через контактную форму на нашем сайте, по электронной почте или WhatsApp. Обычно мы предоставляем подробные расценки в течение 24 часов.

Мы принимаем все основные форматы САПР, включая технические чертежи STEP, IGES, STL, SolidWorks, AutoCAD и PDF. Наша инженерная команда также может работать с образцами или эскизами для разработки вашего литейного решения.

Да, мы можем проектировать и изготавливать литейные формы, штампы и модели на месте. Наши внутренние возможности по изготовлению инструментов обеспечивают лучший контроль качества и более быстрые сроки выполнения заказов.

Да, сбор за пресс-форму необходимо оплатить заранее. Но для заказов большого количества мы вернем стоимость пресс-формы при последующем самовывозе.

Строгого минимального объема заказа нет — мы можем обсудить его в рамках конкретного проекта.

Сроки выполнения зависят от сложности и количества:

- Прототипы: 3-6 недель

- Небольшие партии (1-100 шт.): 4-8 недель

- Крупносерийное производство: 6-12 недель

Срочные заказы могут быть выполнены в кратчайшие сроки.

Наше предприятие сертифицировано по стандарту ISO 9001:2015, и мы осуществляем строгий контроль качества на протяжении всего процесса литья. Мы предоставляем сертификаты материалов, отчеты о проверке размеров и можем предоставить дополнительные сертификаты, требуемые вашей отраслью.

Да, мы будем нести ответственность за все проблемы с качеством, вызванные материалами или производственными процессами, и предоставим бесплатную услугу по исправлению дефектов.

Получите индивидуальное предложение сегодня

Готовы обсудить ваши требования к ковке? Наша инженерная команда готова предоставить экспертную консультацию и конкурентоспособные цены.

Запросить бесплатную расценку

Связанные ресурсы

Изготовление деталей из литой стали на заказ

Поставщик деталей из прецизионного стального литья Литье является важнейшей частью производства...

Исследование мира литья по выплавляемым моделям из нержавеющей стали

Литье по выплавляемым моделям из нержавеющей стали, также известной как нержавеющая сталь...

Инконель 718: состав, характеристики и применение при литье

Inconel 718 — прочный суперсплав на основе никеля, известный своей...