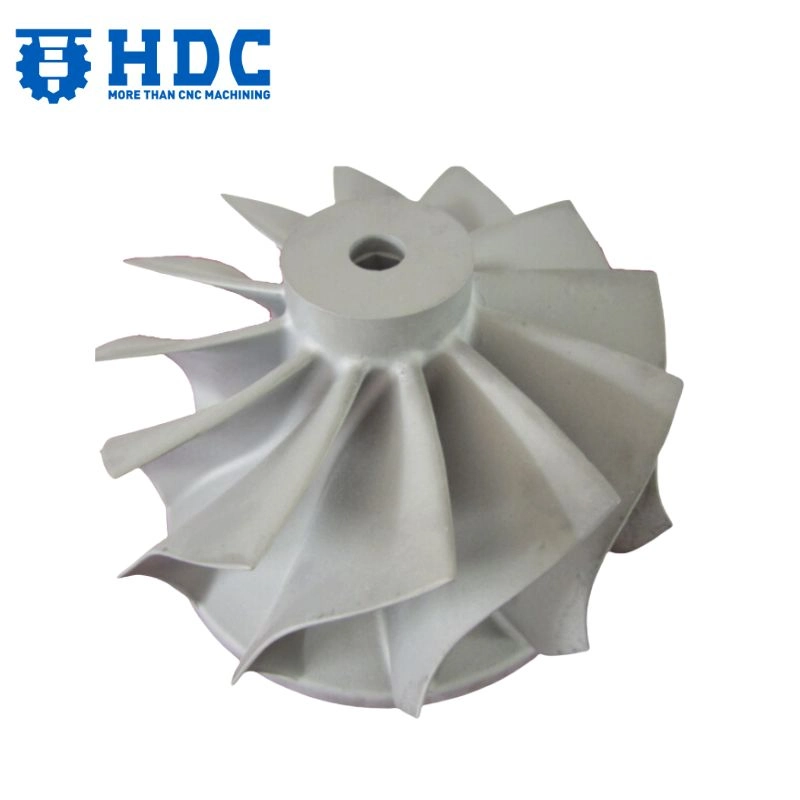

Корпус выхлопной турбины из углеродистой стали/нержавеющей стали/алюминия, изготовленный на заказ методом литья.

Подробная информация о товаре

| Модель №. | HDCT106 |

| Стиль | Корпус турбины, изготовленный методом литья по выплавляемым моделям. |

| Материал | Алюминий, алюминиевый сплав, сталь, стальной сплав, суперсплав, латунь |

| Тип отделки | Необработанный, полированный, анодированный, с электрофоретическим покрытием, с порошковым покрытием, оцинкованный, хромированный, с черным оксидированием |

| Доступный размер | / |

| минимальный заказ | 50 шт. |

| Пользовательский логотип | Доступный |

| Источник | Китай |

| Упаковка и доставка | |

| Вариант доставки | Курьер, воздух, море, железнодорожный экспресс, EXW, FOB, CIF, DDU, DDP |

| Дата доставки | 25-30 дней |

| Транспортный пакет | Индивидуальный, Картон, Поддон |

Harness the full potential of exhaust energy with this custom-cast turbo exhaust turbine housing. Precision-engineered for high-performance turbocharger applications demanding optimized aerodynamics, thermal resilience, and structural integrity, this housing contains the violent expansion of spent combustion gases within intricately sculpted scroll architecture—delivered with the monolithic continuity and flow-tuned geometry only precision casting can provide.

Multi-Alloy Material Optimization: Available in carbon steel for cost-effective durability, stainless steel for superior corrosion and oxidation resistance, or lightweight aluminum for rapid spool and mass-critical applications—each precision-selected to match specific exhaust gas temperatures, boost pressure targets, and vehicle packaging constraints.

Precision-Cast Monolithic Construction: Single-piece investment casting eliminates welded seams, fabricated joints, and leak-prone interfaces common to multi-component housings—ensuring absolute pressure containment, zero parasitic bleed paths, and uninterrupted grain flow throughout the complex scroll profile.

CFD-Optimized Internal Scroll Geometry: Computationally designed volute contours, variable cross-section flow passages, and blended tongue radii are cast directly into the housing architecture—significantly reducing turbulence, preserving exhaust pulse energy, and accelerating turbine spool response.

Tailored Heat & Fatigue Resistance: Material-specific heat treatments—including solution annealing, precipitation hardening, and stress relief—deliver verified creep strength, oxidation stability, and thermal fatigue life for sustained operation in 950°C+ exhaust environments.

Precisely Engineered Mounting Interfaces: CNC-machined turbine inlet flanges, bearing bore alignments, and wastegate ports replicate OEM or custom specifications with micrometer accuracy—ensuring seamless cartridge fitment and leak-free integration with exhaust manifolds and downpipes.

Fully Customizable Turbo Architecture: Manufactured to customer-specific A/R ratios, inlet/outlet configurations, wastegate provisions, and external contour requirements—accommodating everything from direct replacement cartridges to bespoke turbocharger systems for specialty applications.

Proven Power Gain Foundation: Rigid, fatigue-defeating housing structure maintains consistent turbine clearance and aerodynamic efficiency throughout the service life, delivering reliable, repeatable horsepower gains under continuous high-boost operation.

Приложения:

Motorsport & Competition Forced Induction: Ideal for endurance racing, drag, and time-attack vehicles requiring sustained thermal shock resistance and housing integrity at the extreme limits of exhaust gas energy.

High-Performance Street & Drift Applications: Essential for modified turbo systems demanding rapid transient response, reduced lag, and long-term reliability in daily-driven performance vehicles.

Marine Turbocharging Systems: Engineered for propulsion and auxiliary power applications requiring saltwater corrosion resistance and continuous high-load thermal profiles.

Turbocharger Remanufacturing & Custom Upgrades: Accommodates hybrid turbo builds, VNT cartridge retrofits, and one-off compressor/turbine housing pairings with verified flow certification.

Industrial Gas Compressor Packages: Suitable for process gas boosting and power generation turbines requiring certified creep life and extended maintenance intervals.

More than a pressurized vessel, this custom-cast turbine housing is the aerodynamic gateway of your forced induction system—converting raw exhaust pulses into organized, high-velocity energy delivery with every firing event. Whether you’re engineering a 1000hp time-attack machine or repowering a marine diesel, it’s the component that proves power begins with precision-cast, thermally resilient scroll continuity.