Корпус клапана, изготовленный методом литья по выплавляемым моделям для применения в условиях высоких требований

Компания HDC производит высококачественные корпуса клапанов методом точного литья по выплавляемым моделям. Мы обеспечиваем точные размеры, надёжную прочность и гибкость для удовлетворения ваших точных потребностей — от простых до сложных конструкций.

• Точные, сложные формы

• Широкий выбор сплавов

• Качество, сертифицированное ISO

Наши ключевые преимущества

Экспертиза точного литья

С помощью точного литья по выплавляемым моделям мы можем изготавливать клапаны сложной геометрии.

Универсальность материала

Мы работаем с нержавеющей сталью, углеродистой сталью и суперсплавами, способными выдерживать суровые условия.

Начиная с проверки сырья и заканчивая выходной проверкой, мы осуществляем строгий контроль качества для обеспечения качества.

Гибкая поддержка проекта

Независимо от того, нужны ли вам прототипы или полномасштабное производство, мы сделаем процесс гладким и беспроблемным.

Параметры настройки

| Материал |

|

| Размер и вес |

|

| Дизайн |

|

| Чистота поверхности | Обработаны, отполированы, покрыты или изготовлены по индивидуальному заказу в соответствии с требованиями к эксплуатационным характеристикам и внешнему виду. |

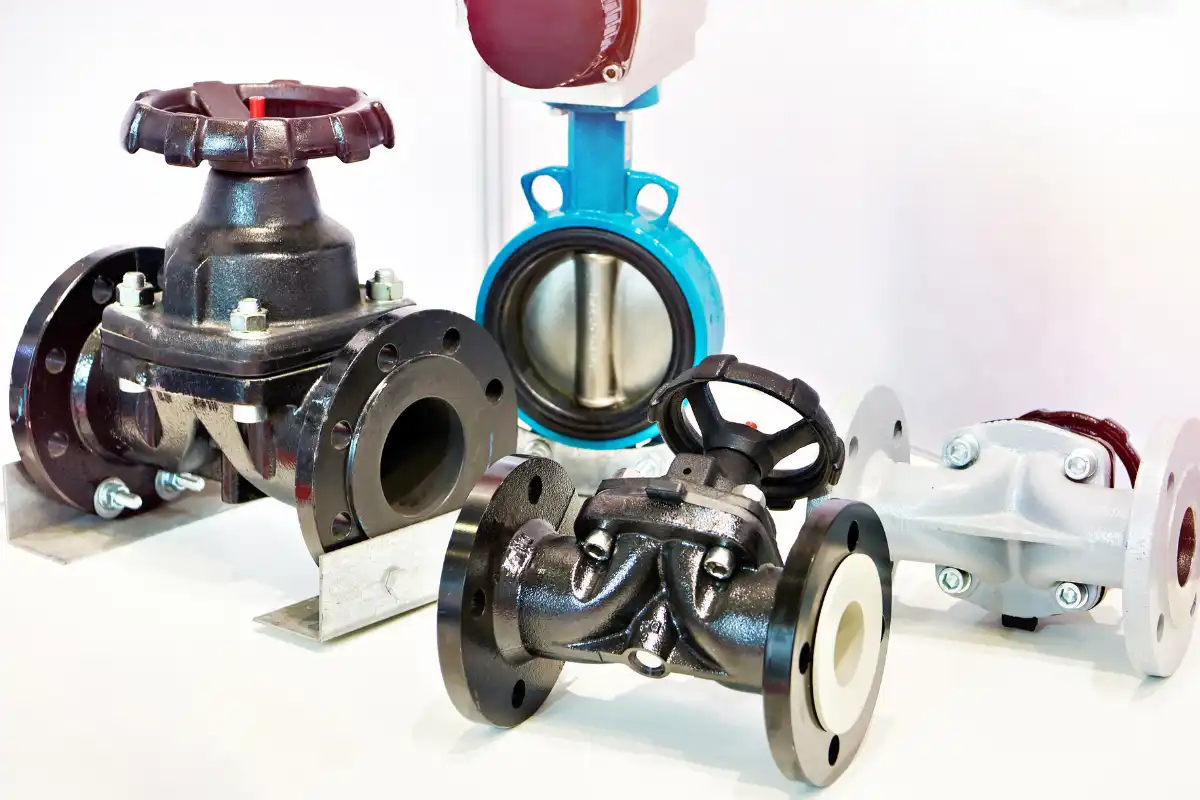

Корпус клапана по типу

Какой бы тип корпуса клапана вам ни был нужен, мы можем отлить его с точностью, обеспечивающей плавный поток жидкости и надежную работу.

Запорный клапан

Простое и эффективное управление переключателем, практически без потери давления при полном открытии.

Шаровой клапан

Точная регулировка расхода, превосходная герметизация, герметичное закрытие и стабильный контроль.

Шаровой клапан

Легко и быстро открывается и закрывается поворотом на четверть оборота, обеспечивая плавный поток и надежную герметизацию.

Обратный клапан

Автоматически предотвращает обратный поток среды, независимо от типа — поворотный или подъемный, всегда надежный.

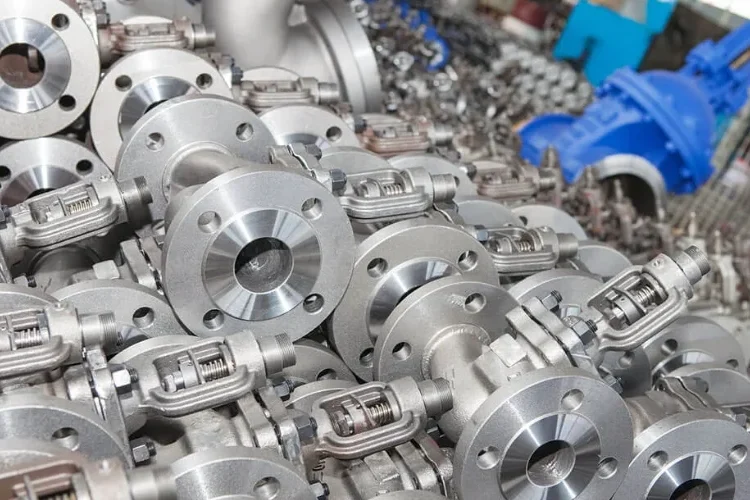

Корпус клапана по материалу

Различные условия работы требуют разных материалов. Мы подбираем сплав, наиболее подходящий для вашего давления, температуры и условий эксплуатации.

Клапан из нержавеющей стали

Устойчивы к ржавчине и долговечны, обладают высокой степенью применимости, что позволяет клапанам легко справляться с водой и общими химическими средами.

Клапан из углеродистой стали

Высокопрочные и доступные по цене клапаны из углеродистой стали способны транспортировать нефть, пар и природный газ.

Клапан из сплава на основе никеля

Высокая термостойкость и коррозионная стойкость, идеально подходит для производства клапанов в химической промышленности и энергетике.

Корпус клапана по проточным отверстиям

Мы можем изготовить прецизионное литье для удовлетворения различных потребностей в проточной части — от простых двухходовых до сложных многопортовых.

Двухходовой клапан

Простой, но эффективный, с превосходной стабильностью и надежностью.

Трехходовой клапан

Легко перенаправить или смешать поток. Надёжно и адаптируется к большинству сценариев.

Четырехходовой клапан

Гибкое переключение впускных и выпускных каналов, используемое для изменения пути потока в сложных системах.

Клапан индивидуальной формы

Мы воплотим ваш проект в жизнь с помощью точного литья. Будь то угловой клапан или многоходовой клапан.

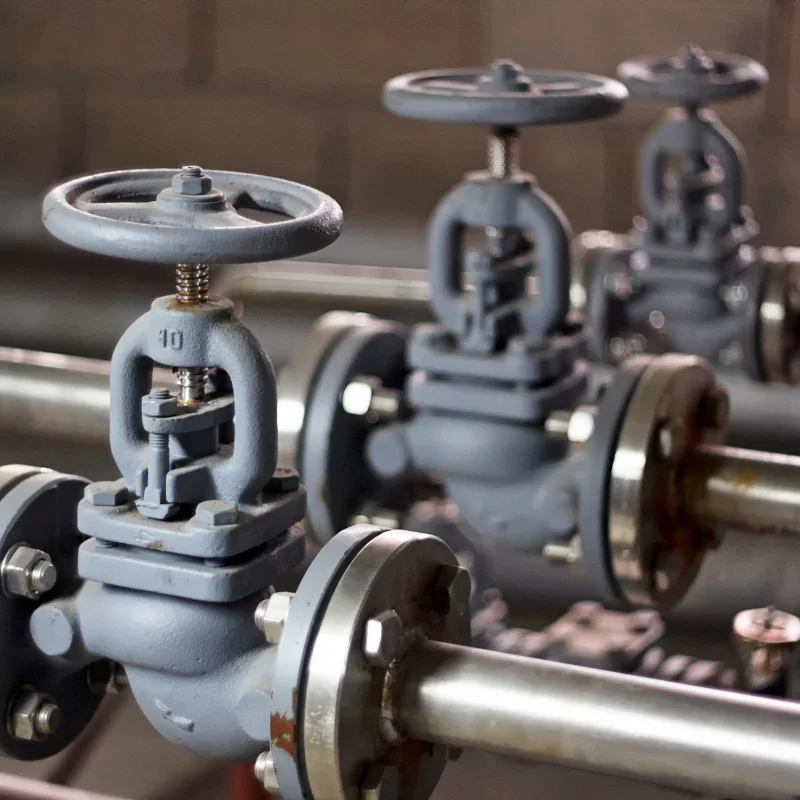

Корпус клапана по применению

Наши отливки используются в самых разных отраслях промышленности по всему миру, бесшумно поддерживая стабильную работу критически важных систем.

Клапан для нефти и газа

Мы отливаем клапаны из сплава на основе никеля, который устойчив к высокому давлению и серной коррозии, идеально подходит для применения в нефтегазовой промышленности.

Химический клапан

HDC обрабатывает материалы с превосходной коррозионной стойкостью, такие как нержавеющая сталь, никелевые сплавы и т. д., обеспечивая безопасную химическую обработку.

Водяной клапан

Наши клапаны устойчивы к коррозии и выдерживают испытание временем — будь то питьевая вода, сточные воды или опреснение морской воды.

Клапан общего назначения

От электростанций до систем отопления, вентиляции и кондиционирования воздуха — наши отливки обеспечивают точную и долговечную работу везде, где этого требует промышленность.

Как выбрать правильный клапан? Простое и практичное руководство

Выбор клапанов порой может быть непростой задачей, но, сосредоточившись на нескольких ключевых моментах, вы сможете принять чёткое и правильное решение. Как и при выборе инструментов, не существует “лучшего” клапана — есть только тот, который “наиболее подходит” для ваших конкретных условий эксплуатации.

Обычно мы рекомендуем продумать следующие три шага:

Шаг 1: Узнайте, с какой жидкостью вы имеете дело.

Тип жидкости определяет, из каких материалов должен быть изготовлен ваш клапан. Начните с вопроса:

- Общие жидкости(Вода, воздух, масло или пар): обычно хорошо подходят стандартные материалы, такие как чугун, углеродистая сталь или нержавеющая сталь 304. Главные критерии здесь — стоимость и практичность.

- Коррозионные жидкости(кислоты, основания или химические растворители): В этих случаях сосредоточьтесь на коррозионно-стойких материалах, таких как нержавеющая сталь 316, сплав 20 или высококачественные сплавы на основе никеля (например, хастеллой).

- Экстремальные жидкости(Шлам с абразивными частицами или пар высокой температуры): эти жидкости могут вызывать сильный износ или термическую нагрузку. Обратите внимание на материалы и производственные процессы, рассчитанные на высокую абразивную стойкость или высокие температуры.

- Высокочистые/чувствительные жидкости(пищевая промышленность, фармацевтика, сверхчистая вода или специальные газы в полупроводниковой промышленности): клапан не должен загрязнять жидкость. Высококачественная нержавеющая сталь со специальной обработкой поверхности (например, электрополировкой) обеспечивает гладкую поверхность и отсутствие остатков.

Суммируя: Сначала выберите правильный материал. Правильный материал — залог долговечности клапана.

Шаг 2: Определите, какие функции должен выполнять клапан?

После выбора материала выберите тип клапана в зависимости от необходимой вам функции:

- Нужен точный контроль расхода? → Рассмотрите вариант использования шарового клапана.

- Нужно ли полностью открыть или закрыть клапан с минимальным падением давления? → Рассмотрите вариант использования задвижки.

- Требуется быстрое открытие/закрытие или необходимо предотвратить обратный поток? → Рассмотрите возможность использования обратного клапана.

- Нужно переключить поток между несколькими трубопроводами? → Здесь на помощь приходит распределительный (четырехходовой) клапан.

Шаг 3: Подтверждение ключевых рабочих параметров

Наконец, подтвердите несколько простых цифр, чтобы убедиться, что клапан идеально впишется в вашу систему:

- Давление: Каково максимальное давление в системе?

- Температура: Какова максимальная температура жидкости?

- Связь: Это фланцевое, резьбовое или иной тип соединения?

Следуя этому простому процессу, вы сможете говорить на одном языке с профессиональными инженерами по клапанам и быстро найти клапан, который действительно соответствует вашим потребностям.

Надеемся, это руководство будет вам полезно. Если вам требуется индивидуальный клапан для ваших конкретных условий, мы будем рады предложить индивидуальное решение, основанное на нашем опыте.

Получите индивидуальное решение по клапанам уже сегодня

От прототипа до серийного производства мы предоставляем услуги литья, отвечающие самым строгим стандартам.

Часто задаваемые вопросы

Мы работаем преимущественно с B2B-клиентами, поэтому существует минимальный объём заказа. Но если вы тестируете новый проект, сообщите нам. Мы найдём гибкое решение.

Нержавеющая сталь, углеродистая сталь, легированная сталь и специальные сплавы. Мы предлагаем большинство металлов, которые обычно используются для литья корпусов клапанов.

Да, конечно. Пришлите нам свой CAD-файл или образец, и мы изготовим изделие по вашим требованиям.

Мы используем литьё по выплавляемым моделям и обработку на станках с ЧПУ. Допуски могут составлять ±0,05 мм или меньше в зависимости от ваших требований.

Да. Возможны полировка, покрытие, покраска и гальванизация.

Обычно 4–6 недель, в зависимости от количества и сложности.

Конечно. Мы работаем с клиентами по всему миру каждый день и можем организовать доставку морем, авиарейсом или курьером.