Поставщик ступиц колес с ЧПУ-обработкой на заказ

Прецизионная механическая обработка с использованием ковки и фрезерования с ЧПУ для картов, велосипедов, мотоциклов и электровелосипедов — нам доверяют производители, реселлеры и команды по всему миру.

• Аэрокосмический алюминий

• 100% настраивается под ваши требования

• Глобальная доставка и экспертная поддержка

Наши ключевые преимущества

От ковки заготовки до готовой ступицы колеса — мы выполняем каждый этап с помощью современного многокоординатного станка с ЧПУ.

Реализуемую производительность

Наши ступицы колес изготовлены специально для реальных условий эксплуатации и имеют конкурентоспособную цену.

От проектирования до окончательной поставки наша команда обеспечивает быстрые ответы и инженерную поддержку.

Мы предлагаем широкий выбор вариантов, соответствующих вашим требованиям, включая дизайн, материал, размеры и т. д.

Параметры настройки

| Материал | Обычно выбирают алюминий марок 6061-T6 и 7075-T6; другие материалы обсуждаются. |

| Размеры | Диаметр, ширина, размер отверстия, высота фланца — все полностью настраивается |

| Расположение болтов | PCD, количество отверстий, размер резьбы и центральное отверстие доступны в стандартных исполнениях или по индивидуальным спецификациям. |

| Посадка подшипника | Прецизионные посадочные места подшипников (прессовая или скользящая посадка) в соответствии с вашими требованиями |

| Заканчивать | Анодирование (прозрачное, черное и т. д.), пескоструйная обработка, полировка и т. д. |

| Логотип / Маркировка | Лазерная гравировка логотипа, серийных номеров или кодов партии |

Ступица колеса по применению

У разных автомобилей разные потребности. Вот наиболее распространённые типы автомобилей, которые мы обслуживаем.

Мотоцикл

Мы изготавливаем ступицы колес под заказ для всех марок мотоциклов, KTM, Honda и т. д. Прочные, надежные и готовые к эксплуатации на дороге.

БМХ

Прочные втулки, способные выдержать любые нагрузки — будь то в скейт-парке или на трассе.

Электровелосипед

Создан для работы с дополнительным крутящим моментом электродвигателей, обеспечивая при этом плавность и бесшумность работы.

Ступица колеса по материалу

Материалы влияют как на производительность, так и на стоимость. Вот наиболее распространённые варианты.

6061-T6 Алюминий

Надёжный и доступный вариант. Хорошая прочность, легко обрабатывается и подходит для большинства применений.

7075-T6 Алюминий

Прочнее и жёстче. Идеально подходит, если вам нужна повышенная прочность или меньший вес для гонок или тяжёлых грузов.

Углеродистая сталь

Высокая прочность и долговечность при низкой стоимости материала. Подходит для проектов с высокой степенью нагрузки или ограниченным бюджетом.

Ступица колеса от Finish

Правильная отделка поверхности может улучшить внешний вид и защиту. Выберите то, что подходит вашему стилю.

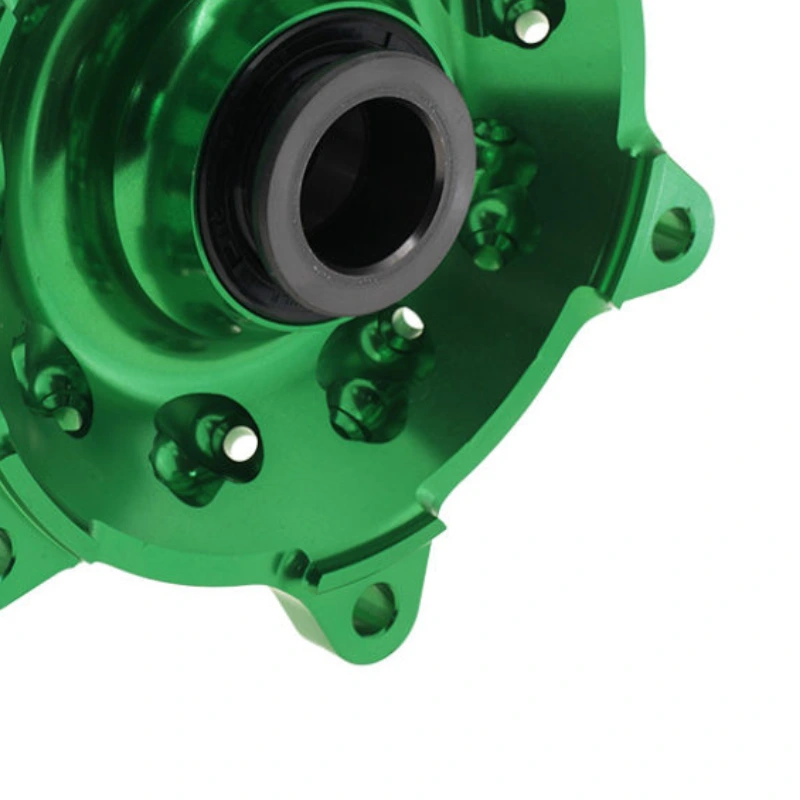

Анодированный

Чистый, красочный и устойчивый к коррозии. Чёрный, красный, серебристый или другие цвета по вашему желанию. Доступны типы Ⅱ и Ⅲ.

Хромированный

Блестящий и классический. Отлично подойдёт тем, кто любит изюминку.

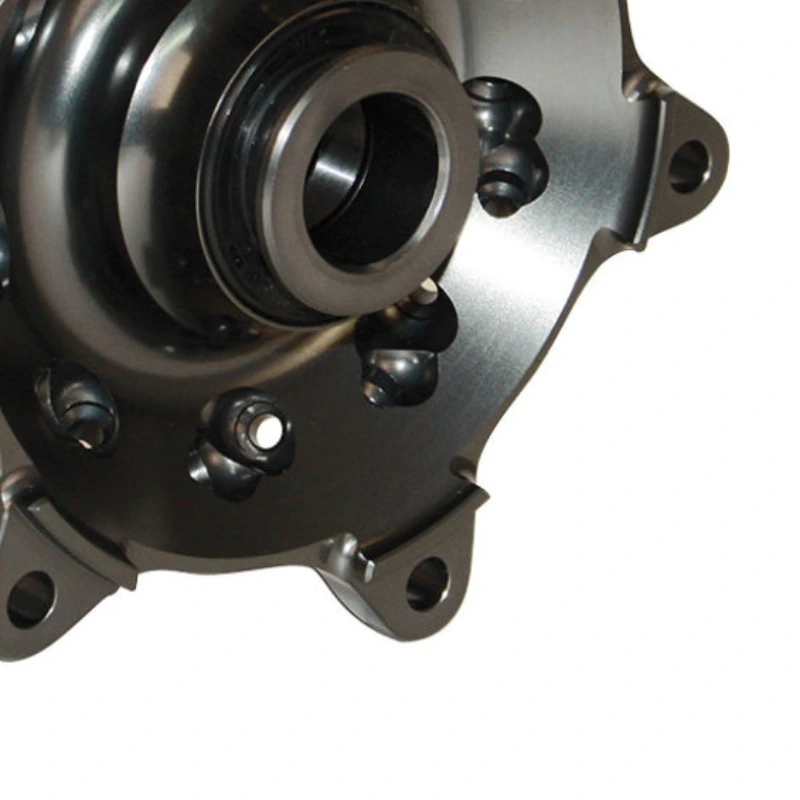

Необработанный

Никакого дополнительного покрытия, только чистый, натуральный вид металла прямо со станка с ЧПУ.

Ступица колеса по цвету

Широкий выбор анодированных и полированных цветов, соответствующих дизайну вашего продукта или фирменному стилю.

Черный

Классический и универсальный. Подходит практически для всех типов автомобилей.

Серебро

Чистый металлический вид с необработанной или полированной отделкой.

Красный

Яркий и спортивный. Обычно используется для BMX, MTB и спортивных велосипедов.

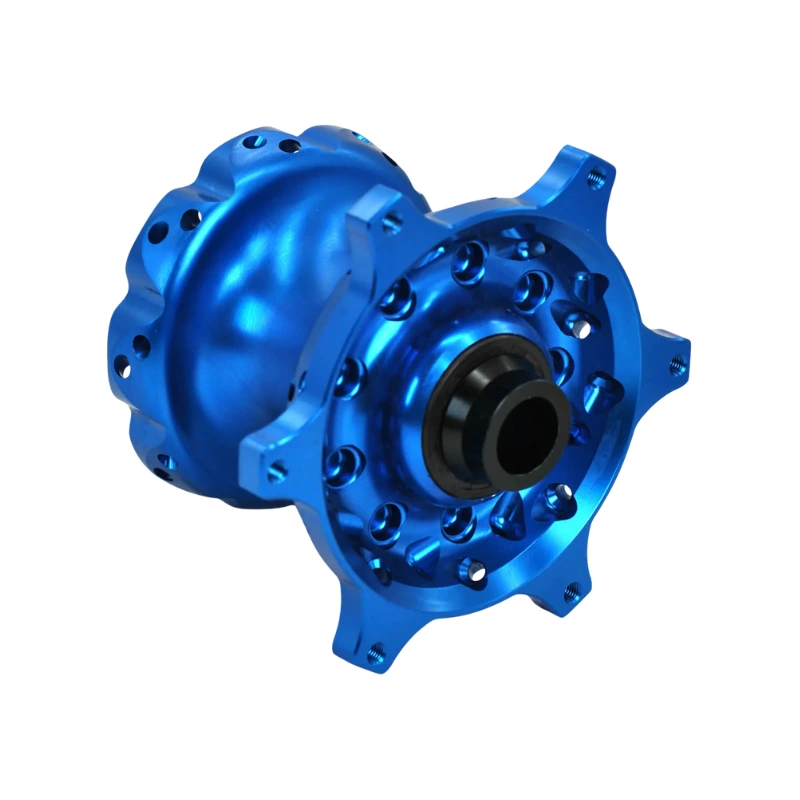

Синий

Яркий и привлекающий внимание. Популярный индивидуальный цвет.

Золото

Премиальный внешний вид с ноткой контраста.

Фиолетовый / Зеленый / Оранжевый

Доступно по запросу. Придаст вашему зданию уникальный характер.

Пользовательские цвета

Мы поддерживаем полноцветную настройку, включая градиентную отделку.

Ступица колеса по характеристикам

Мы специализируемся на изготовлении колёсных проставок под конкретные модели автомобилей. Ниже представлены некоторые из наиболее востребованных брендов, которые мы обслуживаем.

Втулки дисковых тормозов

Для велосипедов с роторами. Прочные, современные и отлично подходят для любой погоды.

Кованые ступицы

Сочетание преимуществ ковки и обработки на станке с ЧПУ, прочность и точность.

Как изготовить ступицу правого колеса по индивидуальному заказу

Планируя заказать ступицу колеса на заказ у такого производителя, как HDC, важно чётко указать свои требования, исходя из конкретных условий эксплуатации. Вот несколько советов, которые помогут упростить задачу.

1. Начните с вашего автомобиля

Определите тип и модель вашего транспортного средства: карт, горный велосипед или электровелосипед.

У каждого варианта своя нагрузка, скорость и требования к установке. Выбор, основанный на вашем конкретном варианте использования, быстро сузит круг возможных вариантов.

2. Узнайте, какая структура концентратора вам нужна

- Передний или задний

- Быстросъемное или сквозное крепление

- Дисковый тормоз или ободной тормоз

Эти данные гарантируют, что концентратор подойдет для вашей системы и будет работать так, как вы ожидаете.

3. Выберите правильный материал

Алюминий марки 6061 обеспечивает надежную работу в большинстве случаев. Для высоконагруженных конструкций более прочным вариантом является алюминий марки 7075. Также доступна углеродистая сталь для дополнительной прочности и меньшей стоимости.

Выбирайте материал после тщательного рассмотрения таких факторов, как бюджет и эксплуатационные требования.

4. Учитывайте отделку и цвет.

От серебристого до анодированного красного или чёрного — ваш хаб может выглядеть так же хорошо, как и работать. Мы предлагаем широкий выбор вариантов отделки поверхности и цветов на заказ, чтобы соответствовать вашему бренду или стилю сборки.

5. Поговорите со своим поставщиком

Хороший производитель поможет проверить размеры, допуски и совместимость. Не стесняйтесь поделиться своими техническими чертежами или спецификациями.

Готовы ли вы создать идеальную ступицу колеса?

Если у вас уже есть чертеж или просто идея, мы готовы помочь превратить ее в высокоточные алюминиевые ступицы колес.

Часто задаваемые вопросы

Конечно. Мы можем изготовить ступицы по вашим 2D/3D-чертежам или выполнить обратное проектирование по физическому образцу.

Для ступиц колёс на заказ с ЧПУ наш типичный минимальный заказ составляет 50–100 штук, в зависимости от сложности. Свяжитесь с нами, чтобы сообщить о ваших конкретных требованиях.

В основном мы работаем с алюминиевыми сплавами марок 6061 и 7075, но по запросу также доступны углеродистая сталь, титан и другие материалы.

Обычно изготовление занимает 2–4 недели, в зависимости от дизайна и количества. Мы подтвердим срок выполнения после рассмотрения вашего проекта.

Да, мы предлагаем различные варианты отделки, включая анодирование в черный, красный, серебристый, синий, золотой цвета, а также в другие цвета по индивидуальному заказу.

Да. Мы работаем с клиентами по всему миру уже много лет и хорошо разбираемся в международных перевозках, таможенном оформлении и экспортной документации.

В идеале — чертеж с размерами и характеристиками. Если нет, просто пришлите нам свою идею или описание изделия — мы вместе уточним детали.