Titanium forging has a silent, yet strong, role to play in the contemporary world. It might not be visible to your eyes, but it is a part of aircraft engines, medical implants, high-performance cars and industrial products. Forged titanium is the material of choice when strength, durability, and reliability are important.

Here you will be in a position to learn what it is, its mechanism, and the reason why industries believe in it and its applications. All has been explained in an easy way, step by step, so you can easily understand it even though you are entirely new to it.

1. What is Titanium Forging?

Titanium forging is the manufacturing technology in which raw solid titanium is modified under great pressure. The metal is not melted but rather the material is heated and pressed or beaten to form a specific shape. In this process, the internal structure of the metal is enhanced and strengthened.

Why forging is preferred:

There is nothing as strong as forged titanium. Take a piece of wood and cut across the grain and it breaks easily. Forging causes the metal to bend to the shape of the part almost to the point that it is almost impossible to bend it again.

Real-Life Case Study: The landing gears of an enormous aircraft are usually made of titanium forgings. It must take a 200 ton aircraft slamming into the landing strip daily and not break.

2. Understanding Titanium as a Forging Material

Titanium is not like iron or aluminum. It possesses a personality that manufacturers have to know.

Physical and Mechanical Properties

Titanium is known to have a high strength-to-weight ratio. It is equally strong as high-strength steel and is 45 % lightweight. It is also very meltable and its melting point is approximately 1,668°C.

Thermal Behavior and Oxidation

Titanium adores breathing oxygen when it is hot. Otherwise, it grows hard brittle skin known as alpha case. Now we apply special metal coatings and atmospheres to stop this in 2026 so that the metal remains pure and strong.

3. Titanium Forging vs Other Manufacturing Methods

| Особенность | Ковка | Кастинг | Обработка | Additive (3D) |

| Прочность | Самый высокий | Середина | Высокая | Переменная |

| Waste | Низкий | Очень низкий | Высокая | Минимум |

| Cost (Large Scale) | Efficient | Cheapest | Expensive | Высокая |

| Внутренние дефекты | Никто | Possible (Air Bubbles) | Никто | Possible |

Which is Best? When you need a component that cannot break (such as a heart valve or a jet engine blade), forging is the winner.

4. Types of Titanium Forging Processes

Various applications require varied forging. Each of the types has its purpose.

Open-Die Titanium Forging

Consider this blacksmithing of a high-tech kind. The titanium is positioned between two flat or slightly shaped dies and beaten.

Why Use it? It works very well on large components such as a 10 foot propeller shaft long which would be prohibitively expensive in a custom mold. It also provides a lot of flexibility and gives the metal freedom to move in various directions.

Closed-Die (Impression-Die) Titanium

It is the cookie-cutter technique. Our two specially machined blocks (dies) come together to force the titanium into a desired and complex shape.

Why Use it? It is the standard of mass production. In case you require 5,000 pieces of the same engine valves of high precision and no defects, closed-die forging will be the most productive option.

Isothermal Titanium Forging

Traditional forging utilizes the cold tools to make the hot titanium harder to move or gives it a chilled state. Under isothermal forging, the temperature of the tools is heated to the same temperature as that of the metal (approximately 900°C or more).

Why Use it? This enables the titanium to remain buttery and soft and to be squeezed into very thin walls and complex shapes that have not been achievable before. It has become the default technique of high-performance fighter jet parts.

Ring-Rolled Titanium

We begin with a heavy piece of titanium, in the shape of a donut, and feed it through a machine having two rollers. The roller squeezes and spins, making the donut wider and thinner, forming a smooth ring.

Why Use it? These rings are very powerful because they have no weld or seam. They are applied in jet engine houses, bearing races, and space rocket high-pressure tanks.

Precision Titanium Forging

Everything about precision forging is about doing it right the first time. Our near net shape part is created by taking our very precise dies and presses, which are under computer control.

Why Use it? Since titanium is costly as well as difficult to cut, precision forging can save money since it minimizes the cost of cleanup machining later. Excellent surface finish and close tolerances are obtained directly out of the press.

5. Titanium Forging Process: Step-by-Step Explanation

The process of forging titanium is a combination of science and art in regard to heavy metals. All the steps are digitally tracked in 2026 so that perfection is achieved.

Billet Prep

A billet is made up of a fine solid of titanium in the form of a log. We remove every bit of dirt before it is ever put in the press. Any grease or dirt on the billet may be trapped in the metal during forging, resulting in a weak point.

Обогрев

The billet is placed in a furnace and heated between 900°C and 1100°C. It is a small band aid and when it is too cold, the titanium will shatter glass. In order to prevent it from breathing oxygen, we frequently smear the billet with a special glass lubricant similar to a protective cover.

деформация

This is the place where magic occurs. The glowing metal is squeezed by a giant hydraulic press, some of which exert up to 50,000 tons of pressure on it. Titanium is a strain-rate sensitive material and this is the reason why we are running the press at a certain pace. Excessively rapid, the metal will overheat due to friction, whereas excessively sluggish, it will become too cool to mold.

Die Design

The die or the mold, is not a shape; it is a map. It must provide an answer to the flow of the metal as well as the degree of contraction that will take place upon coating. We make use of AI simulations in 2026 to know exactly how the titanium will fill the die such that no empty gaps are left.

Trimming

Once the part has been shaped, a thin fringe of unused metal around the edges is frequently left over, which is known as “flash.” To do this, we have the trimming press, which we use to cut this off when the part is still hot.

Heat Treatment (Solution Treating and Aging)

It is the most significant step in strength. We heat the part again and then cool it (very fast) in water or oil. This freezes the atoms in an exceptionally powerful pattern. After that we heat it in the third step (Aging) to ensure that it is tough and a little flexible.

Testing

We don’t guess; we know. We apply the Ultrasonic Testing (UT). whereby sound waves are applied to the part to see inside them and X-rays to watch that there are no microscopic cracks or air bubbles.

6. Common Titanium Forging Grades Explained

The right grade is as much a matter of apportioning the right athlete to a team as that of the other one to a specialty.

Grades 1-4 (Commercially Pure)

These are the purest forms. They are not as tough as the alloys yet they are the leaders of corrosion resistance. Grade 2 should always be your best friend in case you are constructing a tank containing harsh chemicals or a saltwater valve.

Alpha Alloys

These are alloys that include such elements as aluminum. They are perfect in terms of stability at high temperatures. Alpha alloys will be used in case you require a component that remains strong even in a hot jet engine (not exceeding 500°C).

Alpha Beta Alloys (Ti-6AI-4V / Grade 5)

It is the workhorse of the industry. Grade 5 is about 50 percent of the total amount of titanium consumed in 2026. The just-right combination is as tough as steel, yet extremely light and heat treatable. This can be found in aircraft wings as much as in the replacement of human hips.

Beta Alloys

Beta alloys are high-tech. They are also very powerful and may be harder than any other grade. They are applied in fighter jets in specialized springs, fasteners, and high-strength parts because they are more elastic.

7. Benefits of Titanium Forging

To what end do we have all this trouble? Since the outcomes cannot be lost.

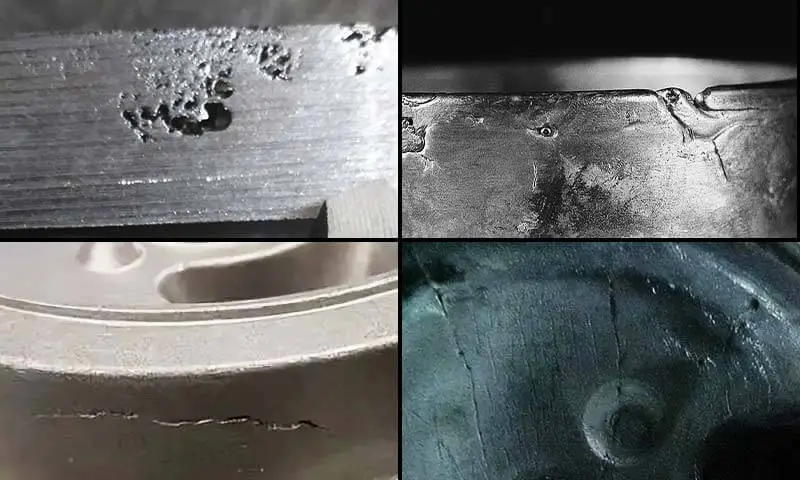

Structural Integrity: In contrast to casting, where it is possible to have porosity (small bubbles of air), forging concerns itself with crushing the metal into a compact and dense substance. It is 100% reliable.

Сопротивление усталости: Titanium forgings are long-lasting. They are capable of loading cyclically, i.e., being Stressed, bent, and vibrated millions of times without the formation of a stress crack.

Grain Flow: The secret sauce. Forging is used to orient the internal grain (fibers of the metal) to the actual shape of the component. This provides a directional strength; the strongest part is strong in the very specific place where it is going to be pressed the most.

Устойчивость к коррозии: It is a natural property of titanium to form a skin (an oxide layer) that is self-healing. On a forgery of titanium, when scratched in saltwater, the protection is at once regrown. It essentially never rusts.

8. Limitations and Challenges

Even there are supermetals, whose hurdles.

The Фактор стоимости: Titanium is a costly mineral to extract as well as to process. A titanium forging will cost you a great deal more than a steel one. But since it is so much longer term, it usually turns out to be cheaper in the long run.

Износ инструмента: Titanium is very tough and requires high heat; thus, it cuts forging dies. A die, which may take 10,000 steel components, may take 1,000 titanium components.

Reactivity: Titanium, as we said, is an oxygen lover. In the factory we must become clean freaks. A million-dollar part can be destroyed by any form of dust or gas contamination.

Innovations of 2026: In order to correct these, we have currently adopted Neat net shape forging. This implies that we cut the part to such an extent that it is near the finished size, so virtually no metal is wasted and this saves you on the cost of raw materials.

9. Applications of Titanium Forging

The titanium in 2026 is the secret behind the high technology in the world.

Aerospace and Aviation

The structure of flight lies in titanium. We make bulkheads, wing spars, and landing gear because these components have to absorb the huge impact of landing thousands of times. Fan blades and compressor disks are forged inside the engines and rotate at an unbelievable speed in high heat.

The modern low fuel consumption jet engines just would not run without the strength of forged titanium.

Медицина и здравоохранение

Your body is an inhuman place for metal, but it is fond of titanium. We are manufacturing orthopedic implants such as hip joints, knee replacements, and spine cages. Forging will make these parts are biocompatible (not rejected by the body) and have the fatigue strength to last 20 or more years inside a human body.

We also make surgical tools with micro precision, which remain sharp and clean after thousands of operations.

Automotive and Motorsports

Weight reduction has become one of the priorities with the transition to Electric Vehicles (EVs) in 2026. High-performance suspension and connecting rod parts and connecting rods are made with forged titanium. The decrease in the upsprung weight allows cars to stabilize better and move over a long distance on one battery charge.

Gearboxes and roll cages in formula 1 and racing are made of forged titanium, where all the grams matter.

Oil, Gas and Marine Industry

Exploration in 2026 will be the deepest deep-sea exploration ever. Forged titanium valves, pumps, and underwater connectors are important, as they do not rust in saltwater and are also able to handle the pressure of the ocean floor, which is crushing. The gold standard is the offshore energy equipment that must remain decades maintenance-free.

10. Titanium Forging Design Considerations

Titanium requires a different design than steel designing. Here is what you need to know:

Толщина стенки: Titanium is not a good filler of thin crevices. Make all wall thicknesses the same so that you do not get cold shuts (when the metal does not fit together).

Sharp Corners: Fillets and Radii. It should always have generously rounded corners (radii). This aids in getting the hot metal to flow well into the die and avoids cracking of the part as it cools down.

Grain Flow Orientation: It is the most important design decision. You ought to make the section in such a way that the natural grain of the forged metal is perpendicular to the point of maximum stress. Imagine the grain of a bat when it runs along; it cannot be broken.

Draft Angles: A draft angle design results in taper-sided sides so that the part can be easily removed out of the mold. This makes the titanium not stick to the die as it reduces in size.

11. Quality Standards and Certifications

Where lives are at stake, we have the most inflexible of manuals.

ASRM B381: This is the standard of alloy titanium and titanium alloy forgings. It is a guarantee that the metal is of the proper chemical recipe.

AMS (Aerospace Material Specifications): The rules, such as AMS 4928 are more difficult to handle and entail certain heat treatments and tests to be conducted on airplane parts.

ISO 13485: This is the gold medal in relation to medical equipment, where all the forged implants are traced from the mine to the operating room.

AS9100: The global quality management system of the aerospace.

12. Titanium Forging vs Other Metal Forgings

| Материал | Масса | Прочность | Расходы | Best Use Case |

| Титан | Очень низкий | Ultra High | Высокая | Jet Engines, Medical Engines |

| Стали | Высокая | Высокая | Низкий | Bridges, Car Frames, Tools. |

| Алюминий | Самый низкий | Середина | Низкий | Window Frames, Soda Cans. |

Titanium is the “Luxury” option. Use steel when you need cheap strength and weight does not matter. Use aluminum when you need low cost and light weight but don’t need extreme heat resistance. Use Titanium when failure is not an option.

13. Cost Factors in Titanium Forging

Why is the price of that invoice bigger than steel? Here is the breakdown:

Raw Material: Titanium is difficult to extract out of the ground and refine and is 10-20x more costly than steel.

Потребление энергии: It consumes a lot of power to have a furnace at 1,000°C for hours.

Tooling Cost: Titanium is so hard that it cuts off the so-called molds (dies) in no time. Substitution of these accuracy instruments increases the cost.

Volume: Forging is costly to install. When you make 1 part, it is highly expensive. When you order 1,000 parts, the cost per part will be much less, as the setup cost will be shared.

14. How to Choose the Right Titanium Supplier

In 2026 it will be a matter of which partner to choose.

The “Paper Trail”: A reputable supplier has a Mill Test Report (MTR) for each of the parts. This is the “DNA” of your metal.

Power: Do they have the heavy presses (1,000 + tons) needed to process the titanium?

Возможности тестирования: They should have nondestructive testing (NDT), such as ultrasonic or Dye Penetrant testing capabilities in-house so that they can detect any hidden defects.

15. Trends and Innovations in 2026

Smart Forging: We are now to have sensors embedded in the dies to detect the real-time temperature and pressure. When something is not right in a part, the computer informs us immediately.

Robotic Handling: It is now the turn of the white-hot billets to be moved by robots. This is less hazardous to the workers and makes sure that the metal is not left in the air too long, which results in oxidation.

Sustainable “Closed Loop” Forging: We are improving in 2026 by recycling 100% of our own scrap of titanium and remelting it back into new billets to decrease the carbon footprint of our factory.

16. Conclusion

Titanium forging is not merely a manufacturing operation but it is the technology that gives us access to the stars and longer and healthier lives. With the knowledge of the personality of this metal and the latest innovations of 2026 we will be able to make the components that we never imagined to be possible.

At HDC, we are experts at implementing such complicated designs in a way that is accurate and cautious. In your aerospace, medical tech, or any other big project, we are here to assist you with the selection of grade and process to use. We are asking you to contact us today to get an individual quote; let us create the future together.

Часто задаваемые вопросы

Is titanium difficult to forge?

It does need very specific temperature control. When it is too cold, it cracks, and when too hot, it takes in gases, which render it brittle.

Is forged titanium stronger than machined titanium?

Generally, yes. Forging aids the shape of the part with the structure of the grain structure, but machining slices through the structure, leaving what are called loose ends, which are more easily broken.

What is the most common titanium forging grade?

The industry standard of titanium is Ti-6AI-4V (Grade 5), which is used in nearly 50% of titanium consumed throughout the world.

How long does it take?

It may require a few weeks to several months or so in the event of complexities to include die design, heating, forging, and testing.

Is titanium expensive?

Yes, it is a premium process. But since the forged parts have a longer lifespan and are lighter, they can save money throughout the product life.