Производитель звездочек, изготовленных на станках с ЧПУ по индивидуальному заказу.

Будучи заводом с широкими возможностями обработки металла, мы предлагаем комплексные услуги по изготовлению зубчатых колес на заказ, которым доверяют предприятия по всему миру.

• Полностью настраиваемый

• Конкурентоспособная цена

• Гибкое производство

Наши ключевые преимущества

Для изготовления звездочек мы используем только высококачественные материалы, такие как сплав 6061-T6 и аэрокосмический сплав 7075-T6.

Используйте станки с ЧПУ для высокоточного производства, обеспечивая жесткие допуски и оптимальную подгонку деталей.

Полностью настраиваемый

Компания HDC предлагает широкий спектр вариантов индивидуальной настройки, включая материал, технические характеристики и цвет.

Крупномасштабное производство

Благодаря десяткам станков с ЧПУ и наличию материалов на складе, мы можем обеспечить крупномасштабное производство в короткие сроки.

Параметры настройки

| Размер цепи (шаг) | 420, 428, 520, 530 или нестандартные стандарты цепей |

| Количество зубов | От 10 до 60 тонн, или полностью по вашему чертежу. |

| Материал | 7075-T6, 6061, сталь, гибридная (зубья из алюминия и стали) |

| Цвет (анодированный) | Черный, серебристый, красный, синий, зеленый, фиолетовый и т. д. |

| Тип отверстия | Круглые, шпоночные, шлицевые или нестандартные профили ступиц |

| Круг болтов | Любой шаблон BCD или ваш технический чертеж |

| Толщина | Стандартная или изготовленная по индивидуальным спецификациям толщина на заказ приветствуется. |

| Стиль дизайна | Цельная, вырезанная, раздельная конструкция или полностью индивидуальная геометрия. |

| Чистота поверхности | Анодированный (тип II / твердый), необработанный или с покрытием |

| Логотип / Маркировка | Лазерная гравировка или без нанесения логотипа по вашему запросу. |

Звездочка по применению

Мы подобрали переднюю звезду индивидуально для каждого типа транспортного средства — с учетом посадки, характеристик цепи и прочности.

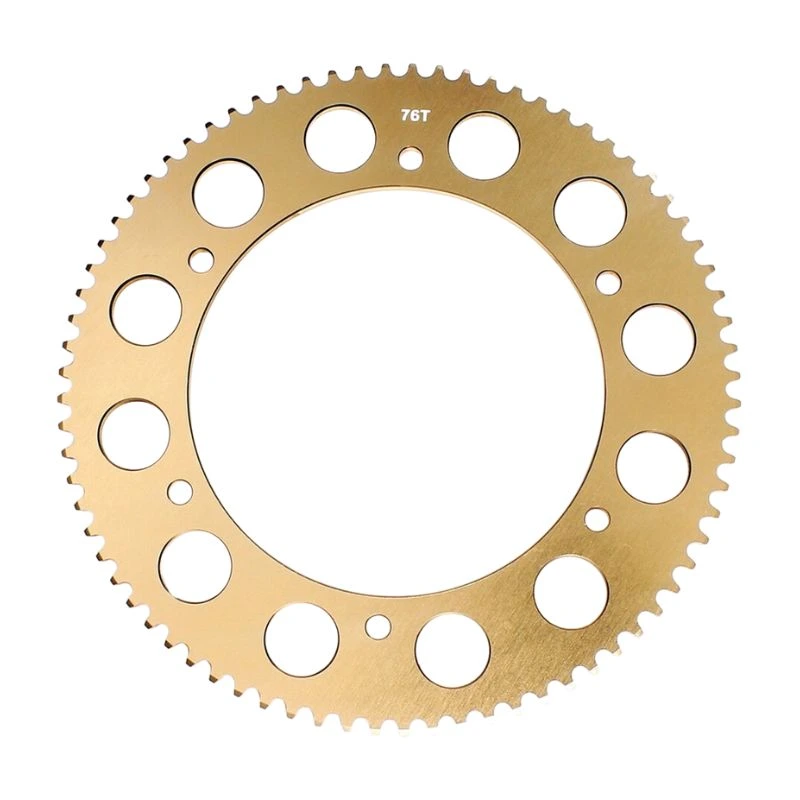

Звездочки для карта

Плоская задняя подвеска, обычно цепь 219/428, 60–85 зубьев. Легкая конструкция для гонок, большое центральное отверстие для крепления оси.

Велосипедные звездочки

Подходит для односкоростных велосипедов/BMX, шаг зубьев 1/8″ или 3/32″. Обычно 25–44 зуба, допускает шлицевое или болтовое крепление.

Мотоциклетные звездочки

Цепи размеров 420/428/520/530, передние и задние. Изготовлены на станках с ЧПУ с возможностью изменения смещения, расположения отверстий или толщины.

Звездочки для квадроциклов

Шаг зубьев 428–530 с более толстым профилем для использования вне дорог. Поддерживает усиленные зубья, долговечное покрытие и установку в соответствии со стандартами OEM.

Звездочки от Teeth & Pitch

HDC поддерживает стандартные размеры цепей и пользовательское количество зубьев.

Цепь 415

Часто используется на электровелосипедах и мини-мотоциклах. Легкие, компактные, обычно имеют от 10 до 54 зубьев.

Цепь 420

Для небольших мотоциклов и картингов. Компактные, гладкие, обычно с 13–50 зубьями.

Цепь 428

Используется в мотоциклах и квадроциклах среднего размера. Обеспечивает хорошее соотношение прочности и веса.

Цепь 520

Популярен среди любителей спортивных и гоночных мотоциклов. Легкий вес и высокая грузоподъемность.

Цепь 525/530

Для больших мотоциклов и квадроциклов. Утолщенный профиль, высокая прочность для высокого крутящего момента.

Индивидуальное количество зубов

10–60 тонн или согласно вашему чертежу. Точная резка для установки цепи и трансмиссии.

Звездочка по цвету

Мы предлагаем прочные, устойчивые к выцветанию и стильные анодированные покрытия с насыщенными цветами.

Черный

Матовое или глянцевое покрытие. Чистый, незаметный вид, подходящий для любого стиля. Самый востребованный цвет для гоночных и кастомных автомобилей.

Серебро

Анодированный алюминий без покрытия, яркий и чистый оттенок. Хорошо сочетается как с винтажным, так и с современным дизайном.

Синий

Стильный и технологичный. Часто выбирается для спорта или использования на гоночной трассе. Хорошо сочетается с полированными или черными компонентами.

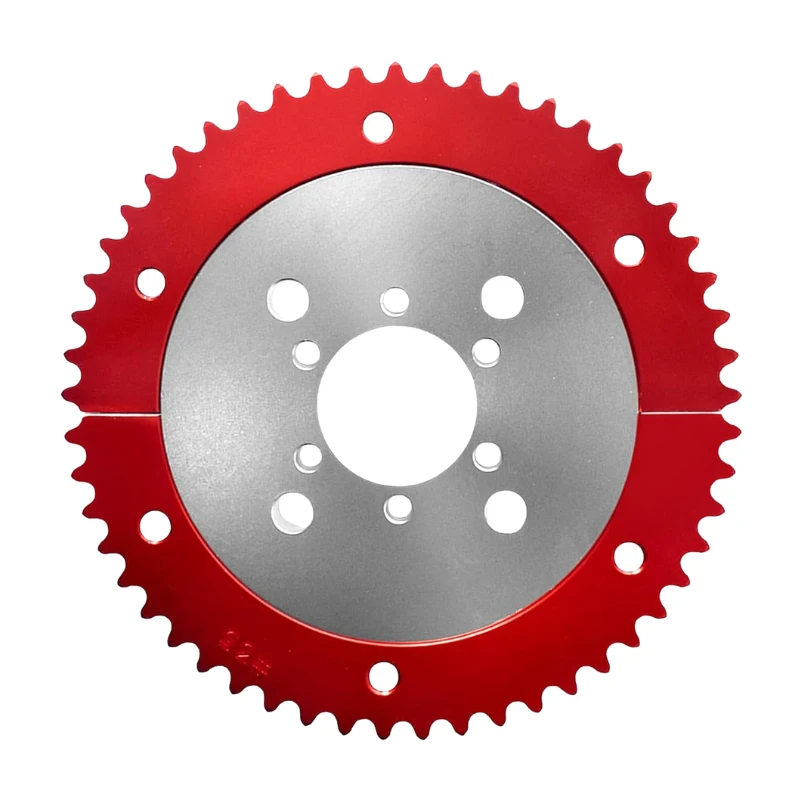

Красный

Яркий и агрессивный. Подчеркивает скорость и производительность. Популярен в автоспорте и при создании BMX-байков.

Зеленый

Свежий, яркий оттенок, идеально подходящий для молодежных или тематических интерьеров. Придаст индивидуальность повседневным и внедорожным образам.

Фиолетовый

Уникальный и яркий. Излюбленный вариант для эффектных кастомных мотоциклов. Создает контраст с серебристыми или черными деталями.

Серый

Сдержанный и индустриальный стиль. Создает ощущение минимализма и профессионального уровня. Идеально подходит для тяжелых или коммунальных работ.

Анодирование на заказ

По запросу мы можем изготовить партии цветов на заказ. Пришлите код Pantone или образец цвета, соответствующий вашему бренду.

Звездочки по отделке

Компания HDC предлагает различные варианты отделки, обеспечивающие привлекательный внешний вид, износостойкость и защиту.

Стандартное анодирование

Гладкое цветное покрытие с базовой коррозионной стойкостью. Доступны все стандартные цветовые варианты.

Жесткий анодированный

Утолщенный поверхностный слой для экстремальной износостойкости и работы при высоких температурах. Рекомендуется для гонок и интенсивной эксплуатации.

Порошковое покрытие

Идеально подходит для агрессивных настроек или требований к установке на широкофюзеляжных автомобилях.

Полированный

Зеркальная поверхность для выставочных мотоциклов или нанесения логотипа. Также доступно с прозрачным анодированием.

Звездочки по конструкции и монтажу

Мы поможем вам выбрать конструкцию, которая соответствует вашим потребностям и сценарию использования.

Прикручиваемый

Наиболее распространенный тип, легко заменяется или модернизируется. Поддерживает стандартные схемы расположения болтов и крепежные отверстия.

Шлицевой привод

Крепится непосредственно на шлицы шатуна или оси без болтов. Типично используется в передних звездочках BMX, MTB и мотоциклов.

Сплит-дизайн

Двухкомпонентные звездочки для быстрой установки. Нет необходимости снимать ось или ступицу.

Легкие вырезы

Выточенные пазы уменьшают вес, сохраняя при этом прочность. Отлично подходят для гонок и тюнинга.

Звездочки по материалу

Выбор материала, соответствующего вашим производственным характеристикам и бюджету, имеет решающее значение для всего проекта.

7075-T6 Алюминий

Наш самый прочный алюминий — легкий, износостойкий, проверенный в гонках. Идеально подходит для конструкций с высокими нагрузками или высокой скоростью.

6061-T6 Алюминий

Доступный по цене и простой в обработке, обладающий высокой прочностью. Отлично подходит для общего использования и изготовления уникальных изделий на заказ.

Высокоуглеродистая сталь

Очень прочные, с превосходной износостойкостью. Часто используются в передних звездочках и при интенсивной эксплуатации.

Легированная сталь

Прочнее и легче обычной стали. Используется там, где важны как долговечность, так и вес.

Смешанные материалы

Алюминиевый сердечник со стальными зубьями или вставками. Сочетает в себе снижение веса и долговечность.

4 ключевых фактора при изготовлении звездочек на заказ

Качественная звездочка начинается с правильных характеристик. Прежде чем приступить к проекту по её доработке, необходимо учесть 4 ключевых фактора.

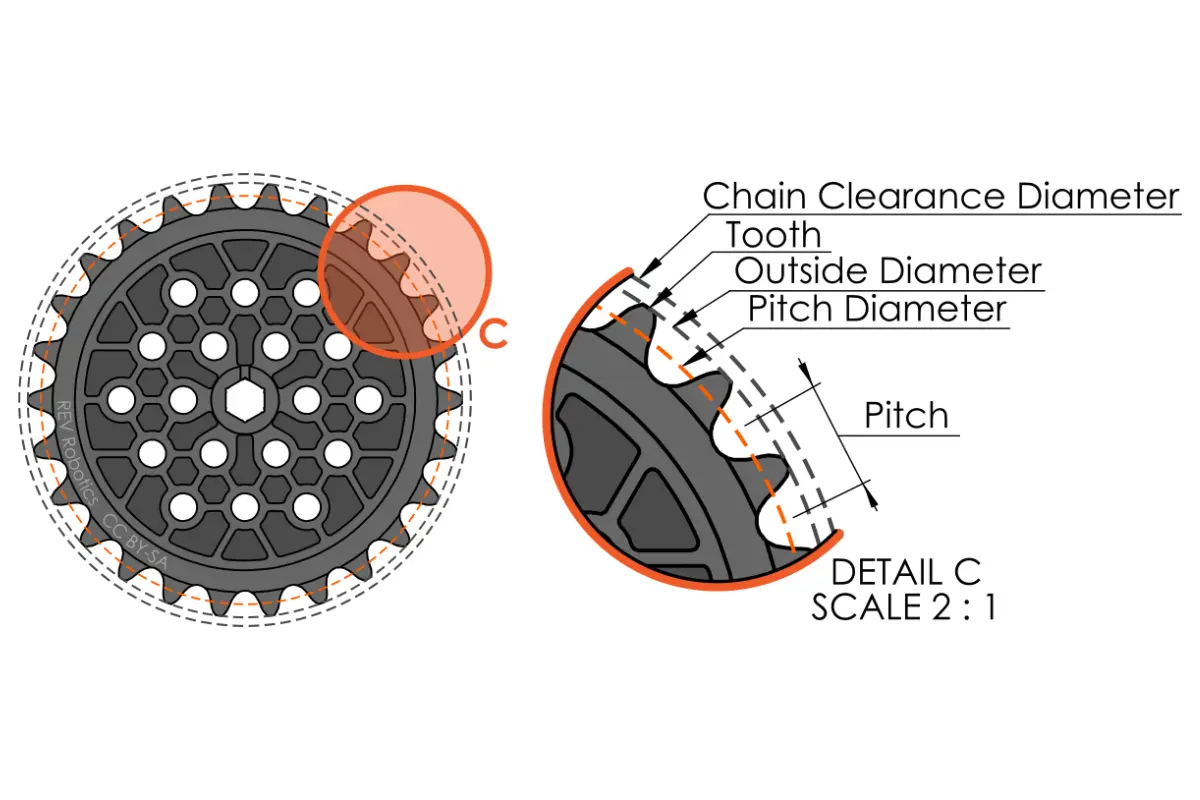

1. Шаг цепи

Шаг цепи — это расстояние между двумя соседними штифтами (или заклепками) цепи. Он определяет размер и расстояние между зубьями звездочки.

Для правильного зацепления звездочки и цепи должны иметь одинаковый шаг зубьев. Использование неправильного шага приведет к проскальзыванию, износу или полной несовместимости. Шаг зубьев также влияет на прочность цепи, скорость и вес.

Проверьте код вашей цепочки — распространенные коды: 420, 428, 520, 530. Если вы не уверены, пришлите нам фотографию или измерьте расстояние между звеньями (обычно в 1/8 дюйма или мм). Остальное мы сделаем сами.

Вот подробная статья, которая поможет вам разобраться в теме: Звездочка и цепь

2. Подсчет зубов

Количество зубьев — это число зубьев на звездочке. Оно влияет на скорость и мощность вашего транспортного средства.

Количество зубьев напрямую определяет передаточное число. Больше зубьев = больше скорость, меньше крутящий момент. Меньше зубьев = больше ускорение, меньше максимальная скорость. Это также влияет на натяжение цепи, её деформацию и износ.

Решите, что вам больше: больший крутящий момент (меньше зубьев) или большая скорость (больше зубьев). Многие райдеры выбирают переднюю звездочку на 13–15 зубьев и заднюю на 40–50 зубьев для баланса. Вы также можете подобрать звездочку, соответствующую вашей существующей.

3. Материал

Разные материалы изнашиваются по-разному. Например, алюминий 7075 лёгкий и отлично подходит для высоких скоростей, но сталь лучше выдерживает удары и нагрузки. Неправильный выбор приведёт к слишком быстрому износу звёздочки или к излишнему увеличению веса.

Для гонок или облегченных конструкций выбирайте сплав 7075-T6. Для повседневного использования или тяжелых нагрузок сталь более долговечна. Если вам нужны и легкость, и долговечность, попробуйте гибрид: алюминиевый корпус, стальные зубья.

4. Тип крепления и BCD

Это определяет способ крепления звездочки к ступице или оси. Включает в себя центральное отверстие, шпоночный паз, отверстия для болтов и диаметр окружности расположения болтов (BCD).

Даже если зубья совпадают, звездочка не подойдет, если крепление не совпадает. Несоответствие окружности расположения болтов или неправильное отверстие для крепления помешают установке. Точность здесь имеет решающее значение.

Вы можете предоставить нам технические характеристики вашей ступицы, чертеж или прислать старую звездочку. Мы поддерживаем болтовые, шпоночные, шлицевые или нестандартные крепления. Если ваша звездочка крепится болтами, обязательно укажите диаметр окружности крепления (BCD).

Готовы собрать свою собственную звездочку?

Высокая точность. Гибкие возможности. Доставка по всему миру.

Мы помогли более чем 100 командам и гонщикам найти идеальный вариант — давайте создадим ваш следующий.

Часто задаваемые вопросы

Для изготовления звездочек на заказ обычно требуется от 100 штук, но мы также поддерживаем небольшие партии, если вы тестируете конструкцию.

Просто пришлите нам чертеж, образец или даже эскиз с указанием основных размеров по электронной почте: sales@hdcmfg.com. Мы принимаем файлы в форматах PDF, CAD или даже фотографии с примечаниями; мы поможем вам превратить их в готовую деталь.

Обычно это занимает от 2 до 4 недель, в зависимости от сложности и количества. Точные сроки мы уточним после ознакомления с вашими требованиями.

Да, черный, серебристый, красный, синий и другие цвета на заказ с помощью анодирования. Мы также можем выполнить твердое анодирование для повышения износостойкости.

Мы осуществляем доставку по всему миру через DHL, FedEx, UPS, а для крупных заказов — морским транспортом. Мы поможем подобрать оптимальный вариант, соответствующий вашим срокам и бюджету.

Конечно. Мы можем нанести ваш логотип лазерной гравировкой на звездочку и предоставить нейтральную или фирменную упаковку, в зависимости от ваших потребностей.