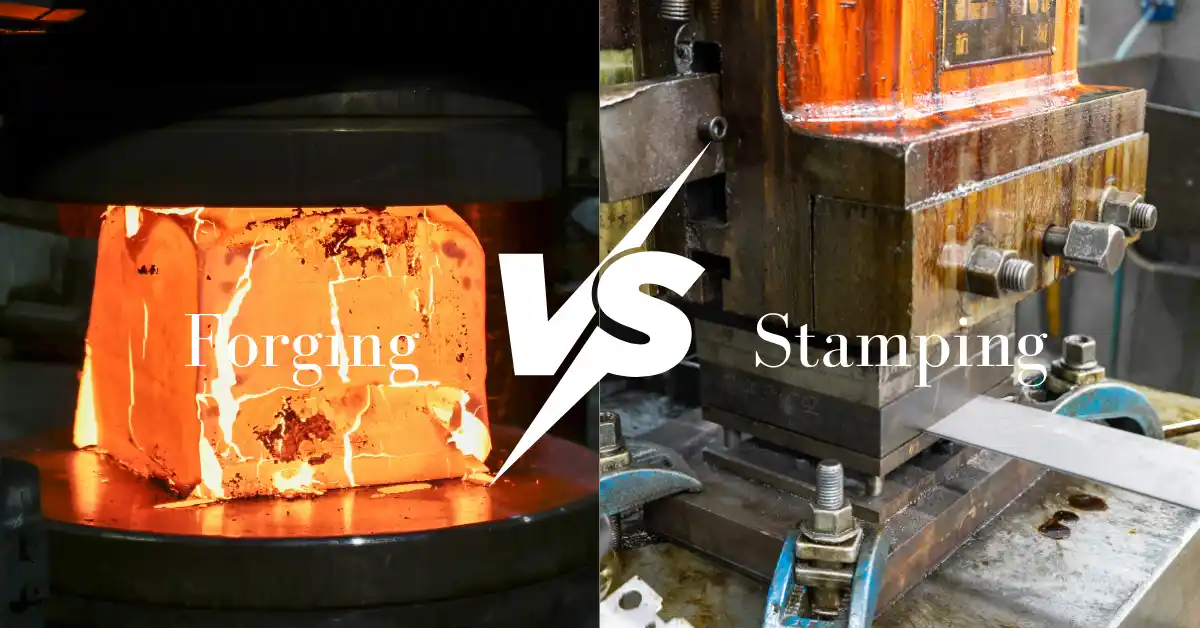

Forging vs Stamping: Differences, Cost, and How to Choose for Your Part

- К: HDCMFG

Quick Summary: Forging vs Stamping — How to Choose

- The real decision isn’t the process name, but choosing the right starting blank that meets performance requirements at the lowest total cost.

- Ковка is typically better for thick, load-bearing, 3D parts that must handle fatigue, impact, or torque.

- Штамповка is usually better for sheet-metal parts with bends, holes, or formed features—especially at high volumes.

- Most parts still require CNC machining on critical features, regardless of forging or stamping.

- The smartest choice comes from optimizing the blank + machining strategy, not comparing unit price alone.

✅ Техническая информация проверена инженерами HDC.

When you’re comparing forging vs stamping, the real decision usually isn’t about the process name. It’s about getting the right starting shape (the “blank”) at the best total cost—while still meeting performance requirements and the tolerances your drawing calls for. And once you factor in ЧПУ обработка, термическая обработка, and finishing, the smartest choice becomes much clearer.

This article breaks down metal forging vs stamping in a simple, practical way so you can choose the right route for your part without overthinking it.

What Is Forging?

Forging is a process that shapes metal using strong compressive force, typically with a hammer or press. Depending on the alloy and the properties you need, forging may be done hot (with heat) or in other controlled conditions. Forging is commonly used when parts must handle real mechanical stress—fatigue, impact, torque, and long service life—especially for thicker, 3D geometries.

If your component looks like a compact “solid” part that carries load, forging is often the first option worth evaluating.

What Is Stamping?

Штамповка (metal pressing) forms parts by placing flat sheet metal into a press where a tool-and-die set cuts and forms the material. Stamping can include punching, blanking, bending, embossing, and other press operations. It’s widely used for high-volume sheet-metal parts where speed, repeatability, and low unit cost are the priorities.

If your part is mostly sheet thickness with bends, holes, and formed features, stamping is usually the natural fit.

Forging vs Stamping: The Simplest Way to Choose

Here’s the fastest mental shortcut.

Forging is usually best for thick, load-bearing, 3D parts that start from billet or bar. Stamping is usually best for sheet-metal parts made from coil or sheet, where the part is formed from a flat blank with holes, bends, or drawn features.

If your part looks like it could be unfolded into a flat pattern, it’s often a stamping candidate. If it looks like a compact 3D mass that takes load, forging is more likely.

Forged vs Stamped Parts: Key Differences That Actually Matter

Starting Material and Part Geometry

This is the biggest difference. Forging begins with solid metal and reshapes it into a near-net 3D form. Stamping begins with sheet metal and forms/cuts it into shape, typically maintaining consistent thickness throughout the part. If you’re choosing between forged vs stamped parts, start here—because geometry usually determines everything else.

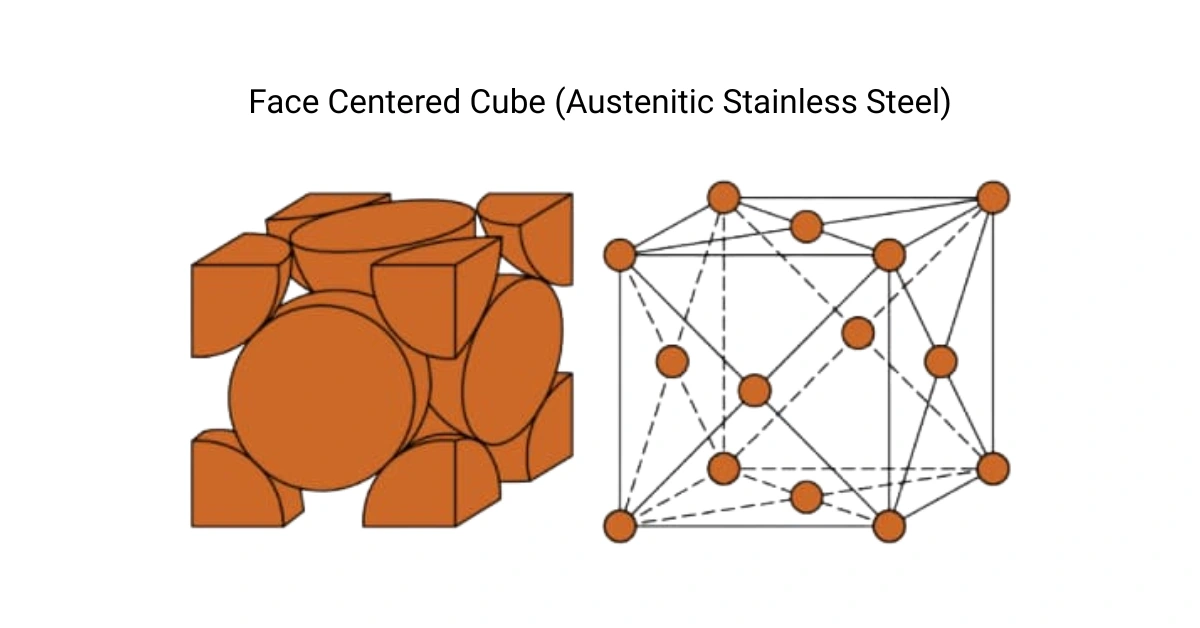

Strength and Performance

Forging is often used for performance-critical components because it’s a reliable route for demanding service conditions. It’s common in heavy-duty equipment and drivetrain-style applications where fatigue, shock, and torque matter. Stamping can still produce strong, durable parts, but it’s typically selected for sheet applications where geometry and production efficiency are more important than thick-section strength.

Volume and Production Speed

Stamping is one of the fastest ways to produce parts at scale. Once the die is ready, throughput can be extremely high and repeatability is excellent, which is why stamping tends to shine in medium-to-very-high volumes. Forging can also scale, but it often becomes especially attractive when the part needs high performance—or when near-net forging reduces machining time and scrap compared to machining from solid bar.

Допуски и качество поверхности

This is where many projects get surprises. Both forged and stamped parts can look “finished,” but if your drawing has tight datums and functional interfaces, you’ll usually need machining somewhere. Bearing seats, precision bores, sealing faces, flatness requirements, threads, and tight positional tolerances typically require CNC finishing. This is why forging vs stamping tolerances is often really a question of “how much machining is needed after forming.”

Near-Net Shape Machining: Where the Big Savings Often Happen

A lot of cost savings comes from combining the right forming method with the right machining plan.

With forging, a near-net blank can dramatically cut CNC time compared to machining a part from solid bar. With stamping, the press can create holes, forms, and bends efficiently—but you may still need selective machining for features that must meet tight tolerance or functional requirements. In both cases, near-net shape machining is about minimizing unnecessary material removal while still hitting the drawing where it matters.

A practical way to think about it is: use forging or stamping to create the shape efficiently, then use CNC machining to make the part precise.

Stamping vs Forging Cost: What Drives Total Cost?

If you’re comparing stamping vs forging cost, don’t focus only on unit price. Compare total delivered cost, including tooling, scrap, machining time, finishing, inspection, and lead time.

What typically drives forging cost

Forging cost is influenced by tooling complexity, how close the forging gets to final shape, material utilization, any heating/heat treatment steps, and the machining required afterward. Even if forging tooling is not cheap, forging can still reduce total cost if it lowers machining hours and reduces waste.

What typically drives stamping cost

Stamping cost is influenced by die approach (simple die vs progressive tooling), how efficiently the sheet material is used, press setup/automation, and secondary operations like deburring, plating, inserts, welding, or selective machining. Stamping tends to win when the part is truly sheet-friendly and volumes are high enough to spread tooling cost across many pieces.

Forging vs Stamping Applications: When Each One Makes Sense

When forging is usually the better choice

Forging is generally the better fit when your part must handle cyclic loads, shock, or torque; when it has thick sections or compact 3D geometry; and when you can benefit from a near-net blank that reduces CNC machining time. Typical examples include shafts and shaft ends, gear blanks and hubs, couplings/yokes, and high-strength flanges.

When stamping is usually the better choice

Stamping is usually the better fit when your part is sheet-based with mostly uniform thickness, needs high repeatability at high throughput, and includes features like holes, tabs, bends, embossing, louvers, or drawn shapes. Typical examples include brackets and clips, covers and shields, housings and sheet frames, and enclosure components.

A Quick Decision Checklist You Can Use Before Sending an RFQ

Start with the part’s starting form. If it’s sheet, stamping is typically the natural choice. If it’s solid, forging is usually the right place to start. Then think about the loads the part will see and the annual volume you need. After that, identify the critical dimensions—because tight functional interfaces usually require machining no matter what. Finally, compare total delivered cost instead of unit price alone, because tooling, machining, scrap, and finishing can flip the outcome.

FAQ: Forging vs Stamping

Are forged parts stronger than stamped parts?

Forging is often chosen for high-stress parts because it typically performs well under demanding loads like fatigue, impact, and torque. Stamped parts can still be very strong when the part is designed for sheet metal and the load conditions match the design.

Is stamping always cheaper than forging?

Stamping often achieves very low unit cost at high volumes, but it isn’t automatically cheaper in every case. Die complexity, material utilization, secondary operations, and required machining can shift total cost. The right comparison is total delivered cost, not unit price alone.

Do forged or stamped parts still need CNC machining?

Often, yes. If your drawing includes tight fits, bearing seats, sealing faces, flatness requirements, precision bores, threads, or tight positional tolerances across datums, CNC machining is typically required to meet the final specification.

Which is better for complex 3D shapes?

Forging is generally better for thick, load-bearing 3D parts. Stamping is better for sheet-based complexity like holes, bends, formed features, and drawn shapes—especially when the thickness stays fairly consistent.

What’s the best way to reduce total cost: forging or stamping?

The best cost strategy is usually choosing the right blank method (forging or stamping) and then machining only the critical features. When the blank is well-matched to the part, you reduce scrap and CNC hours while still meeting the drawing.

Вывод

Choosing between ковка против штамповки comes down to geometry, load requirements, volume, and how much machining your part needs to meet the drawing. Stamping is typically the best route for high-volume sheet metal parts with holes and bends. Forging is typically the best route for high-strength, thick-section 3D parts where mechanical performance matters most.

If you want the quickest path to the right choice, have these ready: your drawing, material, annual volume, and which features are tolerance-critical. With that, it becomes straightforward to recommend forging or stamping (or a hybrid route) that keeps total cost under control while meeting quality expectations.

Узнайте больше из наших сообщений в блоге.

Недавние Посты

Узнайте больше о наших услугах

Решения для ковки на заказ

Мгновенная бесплатная оценка стоимости!