Alliages d'aluminium certifiés, fabriqués avec précision pour une conformité mondiale

Du prototype à la production : obtenez des composants en aluminium légers et résistants à la corrosion avec une traçabilité garantie. 90% des commandes sont expédiées à temps – ou nous compensons les retards.

Pourquoi choisir l'aluminium

Le champion des poids légers

✅Densité: 2,7 g/cm³ (1/3 du poids de l'acier)

✅Parfait pour les applications sensibles au poids : cadres de drones, pièces automobiles, appareils portables.

Résistance exceptionnelle à la corrosion

✅5x plus résistant au brouillard salin que l'acier standard

✅Idéal pour les environnements difficiles : quincaillerie marine, enceintes extérieures, équipements chimiques.

Usinabilité rentable

✅Vitesse de traitement 40% plus rapide que le titane

✅Prototypage et production rapides : géométries complexes, commandes en petites et moyennes séries.

Pourquoi choisir HDC

Assurance qualité des matériaux

✅Certifications des matériaux (RoHS, MSDS) fournis sur demande.

✅Inspections au niveau des lots pour garantir la conformité aux spécifications.

Collaboration axée sur les besoins

✅Chef de projet dédié pour Assistance individuelle.

✅Rapport DFM inclus pour optimiser les conceptions en vue de la fabricabilité.

Précision garantie

✅Précision d'usinage CNC 5 axes : ±0,02 mm (Norme ISO 2768-m).

✅Inspection CMM complète pour les dimensions critiques.

Solutions de bout en bout

✅Capacités de service complètes:CNC, impression 3D, tôlerie, finition de surface.

✅Sans couture intégration multi-processus (par exemple, « CNC + anodisation + gravure laser »).

Expertise de la conception à la réalité

✅Expérience intersectorielle: Plus de 500 projets dans les domaines des technologies médicales, de l'aérospatiale et de la robotique.

✅Équipe professionnelle, suivant un processus strict de la conception à la production

Engagement sans risque

✅Reprise/remplacement gratuit pour les défauts liés au matériel (frais de port couverts).

✅S'engager envers la qualité du produit et la satisfaction du client.

Guide de sélection des alliages d'aluminium

Conçu avec précision pour répondre aux exigences les plus strictes de votre secteur

Découvrez nos 8 alliages de qualité aérospatiale les plus demandés, rigoureusement testés pour offrir :

✅ Rapport résistance/poids optimal

✅ Finitions de surface personnalisables

✅ Cohérence d'un lot à l'autre

Besoin d'aide pour faire correspondre les matériaux à votre candidature

Nos capacités de fabrication de précision

Du prototypage à la production de masse – optimisé pour les propriétés uniques de l'aluminium

Usinage CNC

Nos équipements

Centre d'usinage 5 axes HAAS

Changeur automatique de 60 outils

Précision de positionnement :

±0,005 mm

Taille maximale de la pièce à usiner :

800×500×300mm

Matériaux recommandés :

6061-T6; 7075-T6; 2014-T6

Post-traitement :

Anodisation; Anodisation dure

Impression 3D en métal

Nos équipements :

Système SLM/DMLS

<0,1% atmosphère inerte d'oxygène

Précision dimensionnelle :

±0,1%L (L≤100mm)

Taille de construction maximale :

250×250×325mm

Matériaux recommandés :

Poudre d'aluminium 6061

Post-traitement :

Anodisation; Anodisation dure

Forgeage

Nos équipements

Capacité de la presse : 500-8 000 tonnes

Contrôle de la température de la matrice :

±15°C

Poids maximal de la pièce :

85 kg

Matériaux recommandés :

2014-T6; 6061-T6; 7075-T6

Post-traitement :

Contrôle par ultrasons; Anodisation

Fabrication de tôlerie

Découpeur laser à fibre de 6 kW

Robot de chargement automatisé

Précision de pliage :

±0,25°

Précision de la découpe laser :

±0,1 mm

Matériaux recommandés :

5052-H32; 3003-H14

Post-traitement :

Anodisation; Anodisation dure

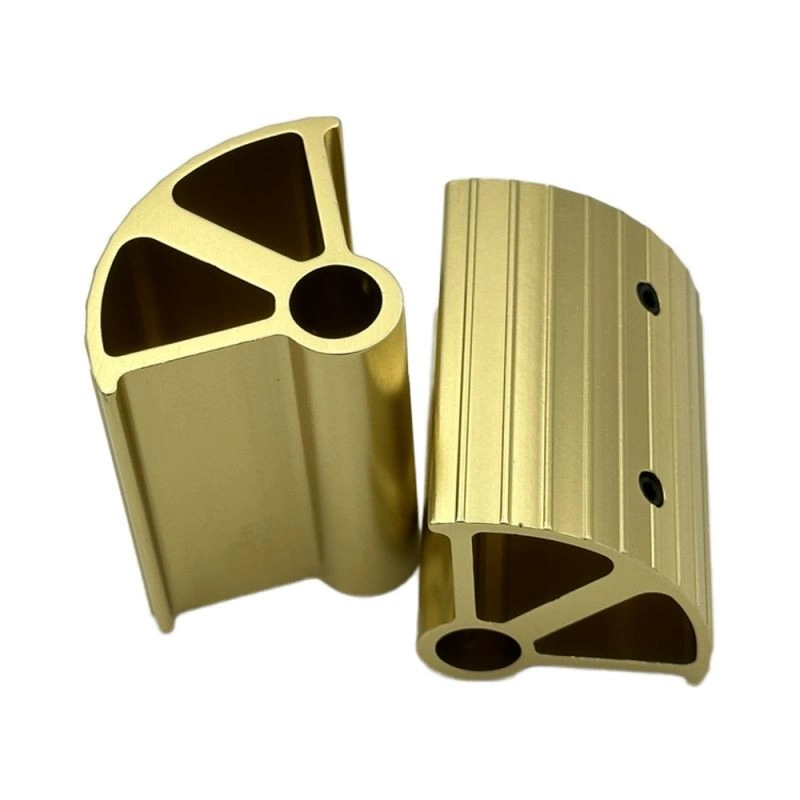

Composants en aluminium de précision

Conçu pour les applications critiques en termes de performances. Notre ligne de production certifiée fournit des pièces en aluminium essentielles à la mission dans tous les secteurs

FAQ

Nous proposons 8 alliages standards de l'industrie : 2007, 2024-T3, 5052-H32, 5083-H116, 6061-T6, 6063-T5, 6082-T6 et 7075-T6. Pour des besoins spécifiques, nous nous approvisionnons en plus de 40 alliages supplémentaires auprès de fournisseurs certifiés. Contactez-nous pour des besoins spécifiques en matériaux.

Nous proposons l'anodisation (standard/dure), les revêtements chimiques et le sablage/texturation. Le choix final dépend du processus de fabrication de votre pièce. Contactez nos ingénieurs pour obtenir des conseils sur la compatibilité.

Oui. Tous les matériaux sont conformes aux normes ISO 9001 et RoHS. Des rapports de test de matériaux avec analyse de composition sont disponibles sur demande.

Les prix varient en fonction du type de matériau, de la quantité commandée et de la complexité. Contactez-nous pour obtenir des devis en temps réel en fonction des taux actuels du marché et de vos spécifications.

Nous refaisons les pièces défectueuses sans frais, couvrons les frais de retour et fournissons une analyse des pannes. La garantie standard de 12 mois s'applique.

Oui. Nous vérifions la composition par analyse spectrométrique, vérifions la dureté et inspectons les défauts. Les enregistrements des tests sont conservés pendant 10 ans.

La plupart des alliages sont exportables librement. Les matériaux de qualité aéronautique nécessitent des permis, tandis que les alliages contenant du plomb nécessitent une documentation. Nous nous occupons de toutes les procédures d'exportation.

Contactez-nous avec des détails pour des exigences précises.

Oui. Nous proposons des optimisations gratuites pour réduire les coûts et améliorer la fabricabilité. Les projets complexes peuvent nécessiter des services d'ingénierie supplémentaires.

Obtenez un devis instantané!

Obtenez un devis rapide pour votre projet en un seul clic ! Demandez un devis instantané dès maintenant !

En contact avec nous

pour toute demande

Découvrez d'autres matériaux proposés par HDC

Au-delà de l’aluminium – métaux et composites spécialisés

pour les applications exigeantes