Fabrication de pièces métalliques sur mesure en Chine (guichet unique)

Simplifiez votre chaîne d'approvisionnement grâce à des processus de fabrication intégrés, notamment l'usinage CNC, la fonderie, le forgeage et bien plus encore.

🛡️ Tout le contenu téléchargé est conservé en toute sécurité et confidentialité.

Capacités de base

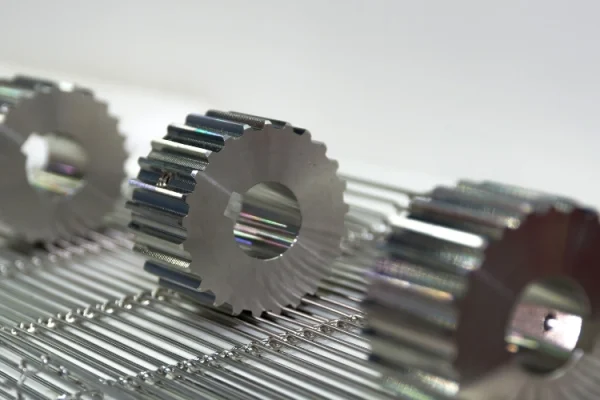

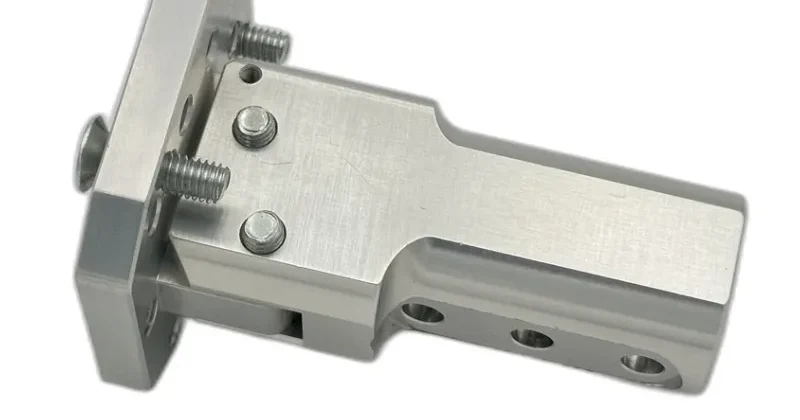

Usinage CNC

- Équipé de 3 axes, 4 axes, et 5 axes Centres d'usinage CNC.

- Tolérance stricte jusqu'à ±0,005 mm.

- Finition CNC des dimensions critiques pour les pièces moulées et forgées.

- Contrôle des dimensions critiques.

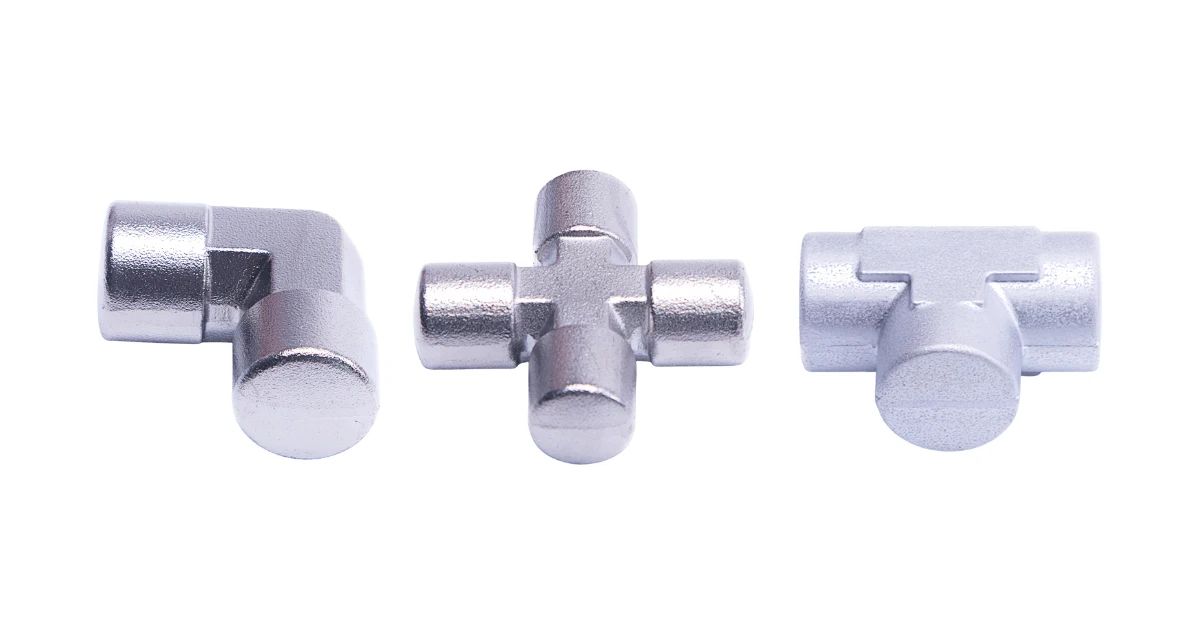

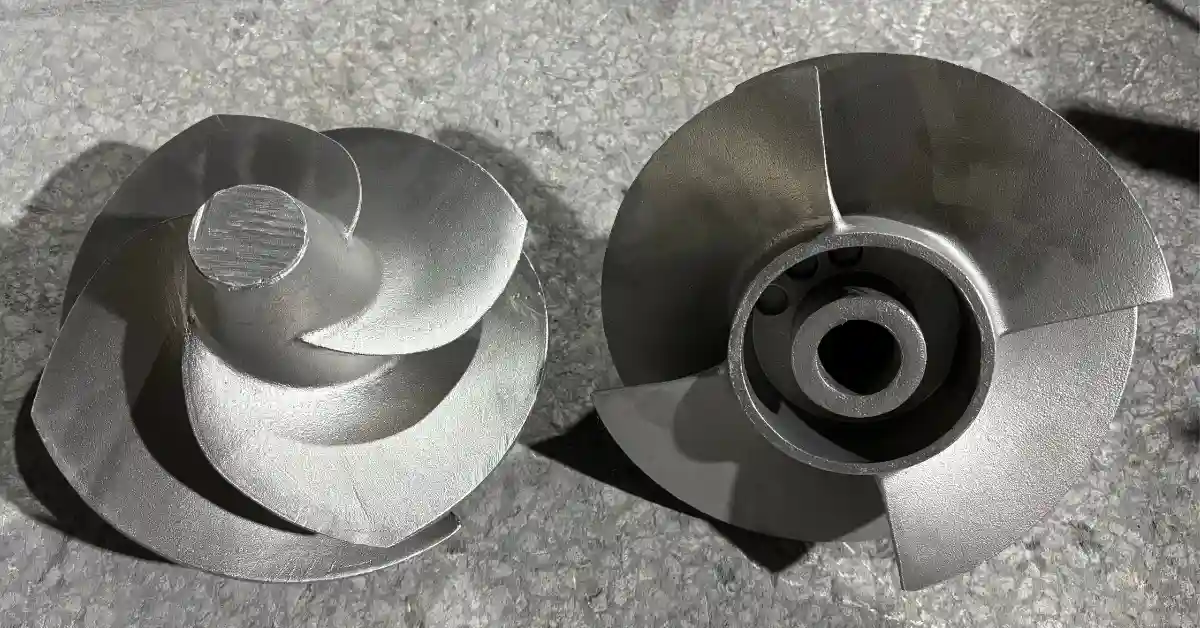

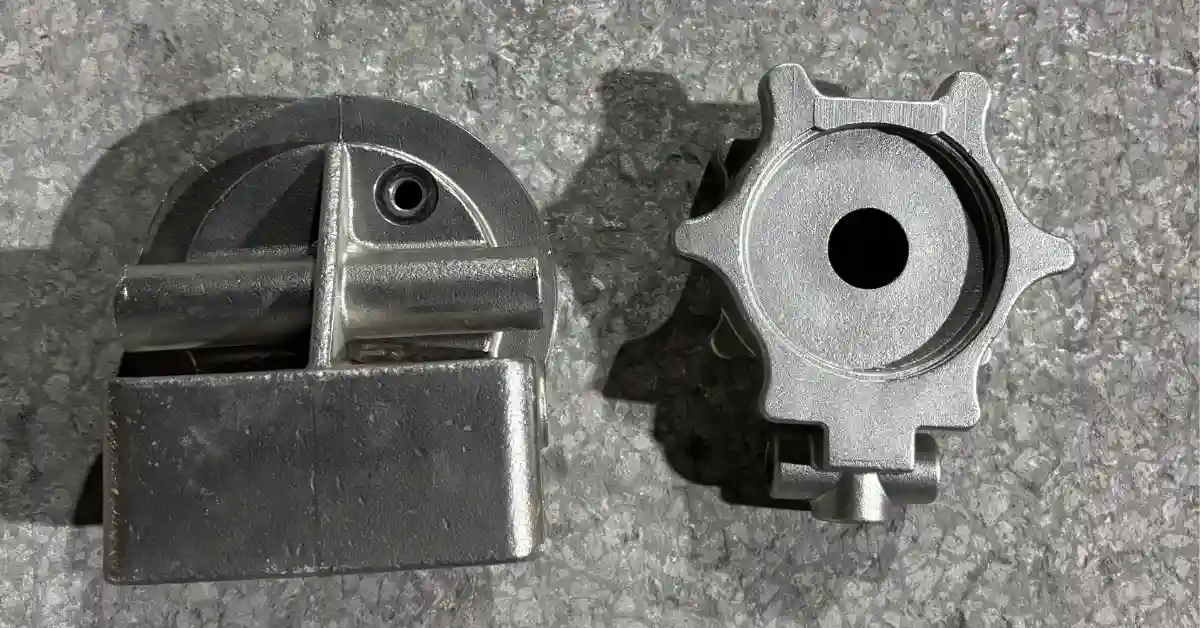

Fonderie

- Moulage de précision avec acier inoxydable, alliage de nickel, et plus encore.

- 50 kg casting unique maximum.

- Tolérances serrées grâce à la finition CNC.

- Solution personnalisée dans procédés de moulage, configuration matérielle, et traitement thermique.

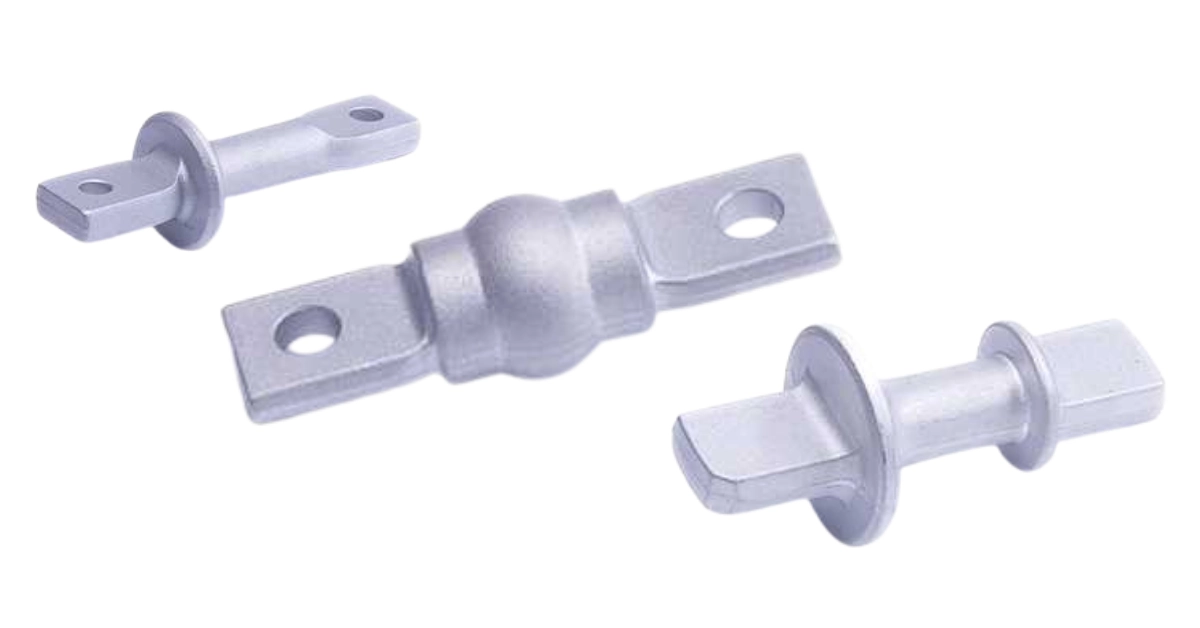

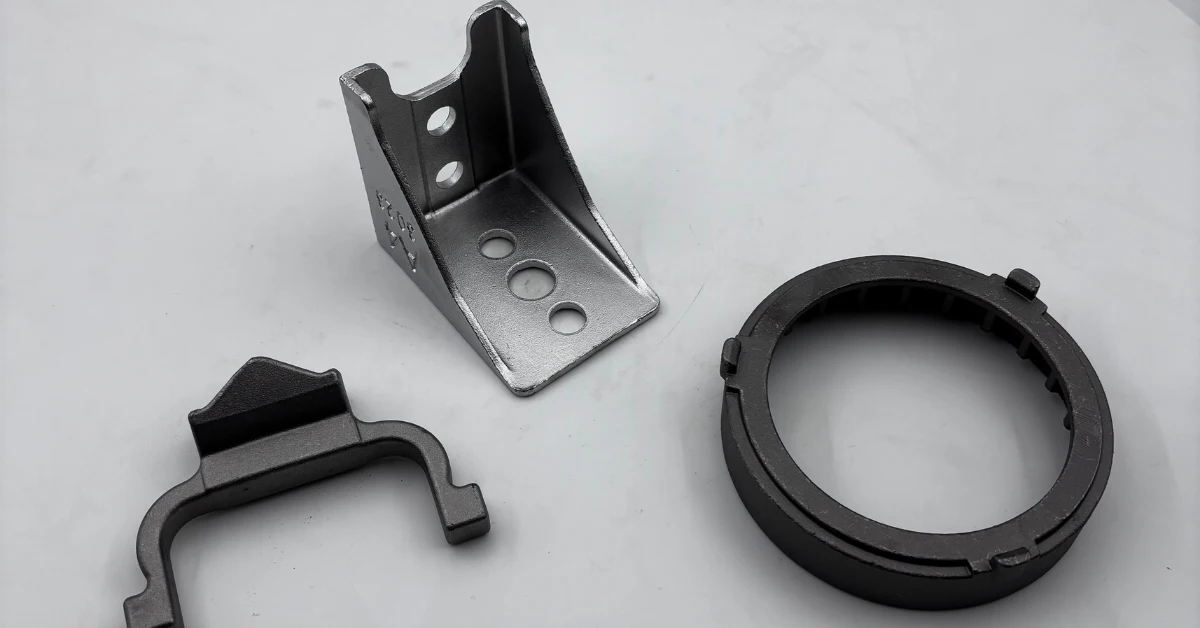

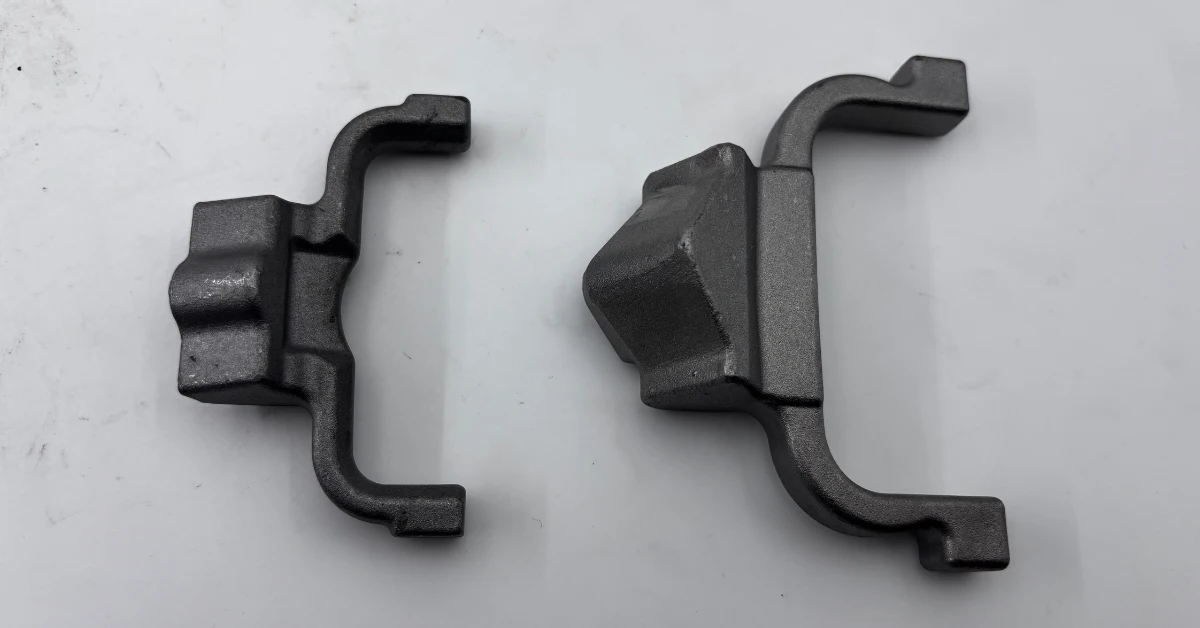

Forgeage

- Forgeage en alliage d'aluminium, Acier Carbone, et en acier inoxydable.

- 30 kg forgeage unique maximum.

- 160T ~ 4000T Presses à forger et presses à vis.

- Le forgeage à froid et le forgeage à chaud sont disponibles.

Service mondial

Nous avons servi plus de 1000 clients dans plus de 50 pays.

Certifié ISO et IATF

Nous avons la certification ISO9001:2005.

Plus de 50 matériaux certifiés

Nous pouvons personnaliser vos pièces métalliques avec plus de 50 types de matériaux différents.

Délais de livraison respectés

Les pièces vous seront livrées comme promis, de 1 semaine à 30 jours.

Pour plus d'informations, veuillez visiter notre Politique de service page.

Pourquoi choisir HDC Manufacturing

Plus qu'un fabricant : votre partenaire en ingénierie et chaîne d'approvisionnement

Un projet concret peut s'avérer complexe et nécessiter la combinaison de plusieurs procédés de fabrication pour produire les composants souhaités. Pour les fabricants de marques, la gestion de multiples fournisseurs impliqués dans différents processus peut rapidement devenir complexe et risquée.

Initialement atelier d'usinage CNC, nous n'avons cessé d'enrichir nos capacités de fabrication et de développer notre chaîne d'approvisionnement, dans le but d'offrir une solution complète à nos clients.

Forts d'une expertise reconnue en usinage CNC, nous réunissons les meilleurs acteurs chinois de la fonderie et du forgeage au sein d'un système qualité unique et fiable. De l'ingénierie à l'approvisionnement, en passant par le contrôle qualité et la logistique, nous prenons en charge toute la complexité : vous pouvez ainsi vous concentrer sur votre produit, et non sur vos fournisseurs.

Valorisez votre marque grâce à des solutions personnalisées

Chez HDC Manufacturing, nous allons au-delà de la simple fabrication. Nous agissons comme un partenaire concret et impliqué pour vous accompagner de la conception à la production de vos produits. Des premiers concepts aux composants finis, nous proposons des pièces métalliques sur mesure et un usinage de précision pour les marques émergentes comme pour les marques établies.

Grâce à l'usinage CNC intégré, au moulage et au forgeage, nous vous aidons à gagner en rapidité, à réduire la complexité de votre chaîne d'approvisionnement et à garantir une qualité constante, afin que vous puissiez vous concentrer sur le développement de votre marque plutôt que sur la gestion de vos fournisseurs.

Processus de commande

Consultation initiale

Partagez les exigences de votre projet avec notre équipe. Nous examinerons votre demande et vous fournirons des conseils d'ingénierie pratiques pour vous aider à démarrer.

Soumission de conception

Envoyez-nous vos fichiers de conception ou travaillez avec nos ingénieurs pour affiner la conception en vue de sa fabrication et de son rapport coût-efficacité.

Devis et révision de conception

Vous recevrez un devis clair et détaillé ainsi qu'une vérification finale de toutes les spécifications avant d'aller plus loin.

Développement de prototypes

Au besoin, nous produisons des prototypes pour valider la conception, l'ajustement et les performances avant la production en série.

Production et contrôle qualité

Une fois l'approbation obtenue, la production à grande échelle démarre, soutenue par des inspections en cours de production et un contrôle qualité rigoureux à chaque étape.

Expédition et livraison

Choisissez votre mode de livraison préféré. Nous assurons une livraison internationale avec des délais de livraison fiables.

Consultez nos ressources pour en savoir plus sur les capacités de HDC.

Matériaux métalliques avec lesquels nous travaillons

HDC Manufacturing travaille avec une large gamme de matériaux métalliques pour répondre à différentes exigences en matière de résistance, de poids et de performance.

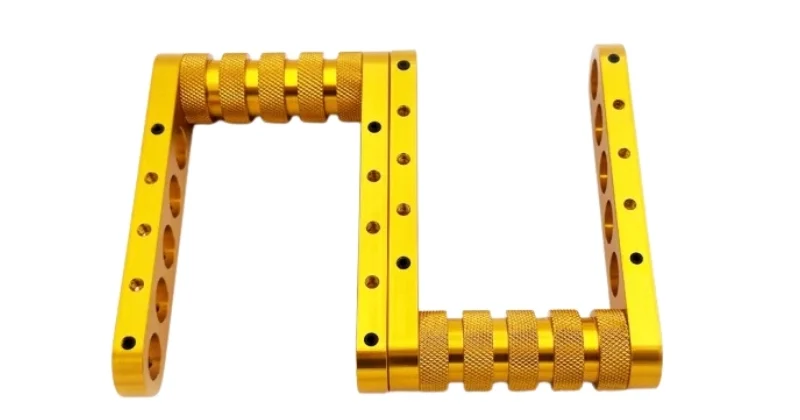

Options complètes de traitement de surface

Grâce à un processus de finition de surface intégré en interne et à une chaîne d'approvisionnement fiable en post-traitement, HDC Manufacturing propose une gamme complète de traitements de surface pour améliorer l'apparence, la durabilité et les performances fonctionnelles des pièces métalliques sur mesure.

| 🔷 Sablage | 🔷 Microbillage |

| 🔷 Anodisation de type II | 🔷 Anodisation de type III |

| 🔷 Revêtement en poudre | 🔷 Peinture |

| 🔷 Zingage | 🔷 Chromage |

| 🔷 Gravure laser | 🔷 Oxyde noir |

Traitement thermique des pièces métalliques

Le traitement thermique joue un rôle essentiel pour obtenir la résistance, la dureté et la durabilité requises des pièces métalliques.

Grâce à des procédés de traitement thermique contrôlés et à une chaîne d'approvisionnement fiable pour le post-traitement, nous proposons une gamme complète d'options de traitement thermique afin d'optimiser les propriétés des matériaux pour différentes applications.

| 🔷 Trempage | 🔷Trempage |

| 🔷 Recuit | 🔷Normalisation |

| 🔷 Traitement par solution |

Contrôle de qualité

Produits fabriqués sur mesure

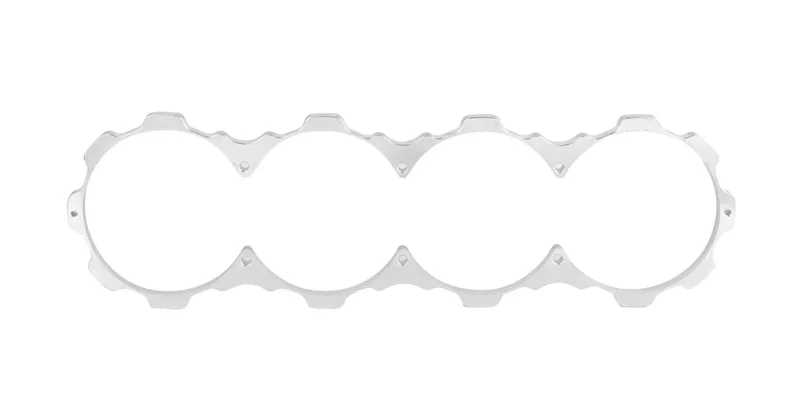

Composants forgés, moulés et usinés CNC pour de multiples industries

Composants automobiles forgés

Composants de moto forgés

Accessoires pour volant et direction

Composants structuraux et d'outillage forgés

Outils, supports et accessoires

Composants de fonderie industrielle

Corps de pompe, soupape, carter d'engrenage

Pièces moulées pour véhicules

Pièces détachées pour voitures, motos, vélos et vélos électriques

Quincaillerie et pièces moulées de structure

Connecteurs, supports et quincaillerie sur mesure

Pièces de moto CNC

Pièces automobiles CNC

Ce que disent nos clients

Questions fréquemment posées

Tout ce que vous devez savoir avant de travailler avec HDC Manufacturing.

Comment puis-je demander un devis ?

Pour obtenir un devis, il vous suffit de nous communiquer les détails de votre projet, y compris les plans, les besoins en matériaux et toute spécification particulière. Notre équipe d'ingénieurs examinera vos informations et vous fournira un devis clair et détaillé dans les meilleurs délais.

Quel est le délai de livraison typique pour les commandes personnalisées ?

Les délais de livraison varient en fonction de la complexité des pièces, de la quantité et des procédés de fabrication. Pour la plupart des projets sur mesure, la production peut être réalisée en quelques semaines. Les délais estimés sont confirmés lors de l'établissement du devis.

Quelles sont les options d'expédition disponibles ?

Nous proposons des options d'expédition flexibles, incluant le fret aérien, le fret maritime et la livraison express. La livraison internationale est possible et des conditions FOB peuvent être convenues selon vos besoins.

Comment HDC Manufacturing garantit-elle la qualité de ses produits ?

La qualité est contrôlée à chaque étape de la production. De l'inspection des matières premières aux contrôles en cours de production et à l'inspection finale, notre système qualité est certifié ISO afin de garantir la constance et la fiabilité de chaque commande.

Existe-t-il une quantité minimale de commande (MOQ) ?

La quantité minimale de commande (MOQ) dépend du type de produit, du matériau et du procédé de fabrication. Nous proposons des volumes de production flexibles et vous invitons à nous contacter afin de trouver la solution la plus adaptée à votre projet.

HDC Manufacturing peut-elle apporter son aide en matière de conception ou de prototypage ?

Oui. Nous proposons des services d'ingénierie et de prototypage pour optimiser votre conception en termes de fabricabilité, de performance et de coût avant la production en série.

Quels modes de paiement acceptez-vous ?

Nous acceptons les paiements sécurisés, notamment les virements bancaires, PayPal et d'autres options courantes. Les modalités de paiement sont confirmées lors de la commande pour plus de clarté et de transparence.

Offrez-vous un soutien aux nouveaux importateurs ?

Oui. Nous travaillons régulièrement avec des importateurs débutants et leur fournissons des conseils sur les Incoterms, le dédouanement et les options d'expédition afin de garantir un processus d'importation sans encombre.

Comment puis-je contacter HDC Manufacturing pour obtenir plus d'informations ?

Vous pouvez nous contacter via notre page de contact, par courriel ou par téléphone. Notre équipe est à votre disposition pour discuter de votre projet et répondre à toutes vos questions.

Donnons vie à votre projet

Téléchargez vos dessins techniques (STEP, IGES ou PDF) pour obtenir un avis professionnel sur la conception pour la fabrication (DFM) et un devis compétitif sous 24 heures.

* Analyse technique disponible. Un accord de confidentialité peut être signé sur demande.