Tabella di riferimento dei comandi G-Code

- Di: Italiano:

Il G-code (Geometric Code) è il linguaggio di programmazione universale utilizzato per controllare le macchine CNC (Computer Numerical Control). Sviluppato negli anni '50 al MIT, il G-code rimane la spina dorsale della moderna lavorazione CNC, consentendo un controllo preciso sui processi di lavorazione come fresatura, tornitura e taglio laser.

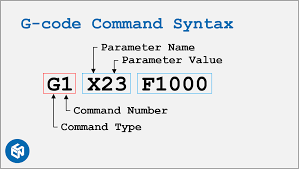

Ogni comando G-code inizia con una lettera (ad esempio G, M o F) seguita da valori numerici, che indicano alla macchina di:

- Controllo del movimento (comandi G): Determina il percorso e la velocità dell'utensile (ad esempio, spostamento verso coordinate, movimento lineare/ad arco).

- Gestisci funzioni (comandi M): Gestire le azioni di avvio/arresto (ad esempio, rotazione del mandrino, cambio utensile, accensione/spegnimento del refrigerante).

Sebbene standardizzati secondo ISO 6983, esistono delle variazioni tra i produttori di macchine (ad esempio, Fanuc, Haas, Siemens). Questa tabella copre 90% di codici G per uso generico. Per le funzioni avanzate (5 assi, macro), consultare sempre il manuale della macchina per verificarne la compatibilità.

Concetti chiave:

- Comandi modali: Rimanere attivi fino alla sostituzione (ad esempio,

G01rimane in modalità movimento lineare). - Comandi non modali: Eseguire una volta (ad esempio,

G28ritorna alla posizione iniziale). - Unità:

G20(pollici) /G21(millimetri). - Sistemi di coordinate:

G54–G59(compensazioni di lavoro),G90(posizionamento assoluto),G91(posizionamento incrementale). - Esecuzione sequenziale: La macchina legge il codice riga per riga, dall'alto verso il basso, Nessun salto o loop a meno che non si utilizzino funzionalità avanzate

Categorie G-Code

| Categoria | Comandi di esempio | Funzione primaria |

|---|---|---|

| Controllo del movimento | G00, G01, G02, G03 | Movimento utensile (rapido/lineare/arco) |

| Selezione del piano | G17, G18, G19 | Selezionare il piano di lavoro (XY/XZ/YZ) |

| Unità e misure | G20 (pollici), G21 (mm) | Imposta il sistema di misura |

| Sistemi di coordinate | Da G54 a G59, G92 | Definire offset di lavoro o coordinate temporanee |

| Compensazione utensile | G40, G41, G42, G43 | Regolare in base alle dimensioni/lunghezza dell'utensile |

| Cicli in scatola | Da G81 a G89 | Routine di foratura/maschiatura automatizzate |

| Controllo del mandrino | M03, M04, M05 | Avvia/arresta la rotazione del mandrino |

| Controllo del refrigerante | M08, M09 | Accendere/spegnere il refrigerante |

| Controllo del programma | M30, M02 | Fine programma/reset macchina |

| Funzioni speciali | G28, G53 | Ritorna alle coordinate di casa/macchina |

Nota: I programmi di base 80% utilizzano solo: G00/G01, G17/G20/G21, M03/M05, e M30.

Tabella di riferimento dei comandi G-Code comuni

| Comando | Funzione | Parametri | Esempio | Appunti |

|---|---|---|---|---|

| G00 | Posizionamento rapido (movimento senza taglio) | X, Y, Z (coordinate di destinazione) | G00X10Y5Z2 | Evita collisioni; non si verificano tagli. |

| G01 | Interpolazione lineare (movimento di taglio) | X, Y, Z, F (velocità di avanzamento) | G01 X20 Y15 Z0 F150 | Mantenere una velocità di avanzamento costante per la finitura superficiale. |

| G02 | Interpolazione circolare in senso orario | X, Y, I, J, K (offset del centro dell'arco) | G02 X30 Y30 I5 J0 | I/J/K definiscono il centro dell'arco rispetto al punto di partenza. |

| G03 | Interpolazione circolare antioraria | Uguale a G02 | G03 X40 Y20 I0 J-5 | Utilizzato per archi e cerchi. |

| G17 | Selezione del piano XY | Nessuno | G17 | Piano predefinito per la maggior parte delle operazioni di fresatura. |

| G18 | Selezione del piano XZ | Nessuno | G18 | Utilizzato per operazioni di tornitura. |

| G19 | Selezione del piano YZ | Nessuno | G19 | Raramente utilizzato nella fresatura standard. |

| G20 | Unità in pollici | Nessuno | G20 | Imposta tutti i valori in pollici. |

| G21 | Unità metrica | Nessuno | G21 | Imposta tutti i valori in millimetri. |

| G28 | Ritorno alla posizione iniziale | X, Y, Z (facoltativo tramite intermedio) | G28 X0 Y0 Z0 | La macchina si sposta verso il punto di riferimento. |

| Il G40 | Annulla compensazione taglierina | Nessuno | Il G40 | Disabilita la compensazione del raggio utensile. |

| G41 | Compensazione della fresa sinistra | D (numero di offset del raggio utensile) | G41D1 | Compensa il raggio dell'utensile a sinistra del percorso. |

| G42 | Compensazione della fresa a destra | D (numero di offset del raggio utensile) | G42 D2 | Compensa il raggio dell'utensile a destra del percorso. |

| G43 | Compensazione della lunghezza dell'utensile | H (numero di offset dell'altezza dell'utensile) | G43 H3 | Si adatta alla lunghezza dell'utensile; essenziale per le configurazioni multi-utensile. |

| G54 | Sistema di coordinate di lavoro 1 | Nessuno | G54 | Seleziona l'offset di lavoro predefinito (G54–G59). |

| G80 | Annulla modalità di movimento | Nessuno | G80 | Annulla i cicli (ad esempio foratura, maschiatura). |

| G90 | Posizionamento assoluto | Nessuno | G90 | Tutte le coordinate sono relative all'origine. |

| G91 | Posizionamento incrementale | Nessuno | G91 | Le coordinate sono relative alla posizione attuale. |

| M03 | Avvio del mandrino (senso orario) | S (velocità del mandrino) | Modello M03 S2000 | Il mandrino ruota in senso orario a 2000 giri/min. |

| M04 | Avvio del mandrino (senso antiorario) | S (velocità del mandrino) | Modello M04 S1500 | Utilizzato per operazioni di taglio inverso. |

| M05 | Arresto del mandrino | Nessuno | M05 | Arresta il mandrino dopo l'operazione. |

| M06 | Cambio utensile | T (numero utensile) | M06 T5 | Cambio utensile automatico (richiede ATC). |

| M08 | Refrigerante acceso | Nessuno | M08 | Attiva il refrigerante di allagamento. |

| M09 | Liquido refrigerante spento | Nessuno | M09 | Disattiva il refrigerante. |

| M30 | Fine programma e ripristino | Nessuno | M30 | Termina il programma e reimposta la macchina. |

| F | Velocità di avanzamento | Valore di avanzamento (unità/min o unità/giro) | F200 | Impostare in G94 (unità/min) o G95 (unità/giro). |

| S | Velocità del mandrino | Valore RPM | S3000 | La velocità dipende dal materiale e dal tipo di utensile. |

| T | Selezione dello strumento | Numero dello strumento | Tipo 4 | Prepara lo strumento per il comando M06. |

FAQ

Devo memorizzare tutti i codici G?

No. Il software CAM moderno genera la maggior parte del codice automaticamente. Concentrati sulla comprensione dei comandi comuni come G00, G01, M03, e M30.

I codici G sono gli stessi per tutte le macchine?

Le basi sono universali, ma le funzionalità avanzate variano a seconda del marchio. Ad esempio:

- Haas: G187 (modalità ad alta velocità)

- Fanuc: G05.1 (levigatura)

Per i dettagli, consultare sempre il manuale della macchina.

Un G-code errato può danneggiare la macchina?

Sì. Ad esempio:

Utilizzando G00 (movimento rapido) invece di G01 (taglio lento) → L'utensile urta il pezzo in lavorazione.

Dimenticare M05 (arresto del mandrino) → Il mandrino continua a ruotare anche dopo la fine del programma.

Come posso utilizzare il G-code in modo sicuro?

- Prima prova: esegui i programmi in modalità "dry run" (senza tagli).

- Modalità blocco singolo: esegue una riga alla volta per rilevare gli errori.

- Impostazioni di backup: annotare gli offset della macchina prima di modificarli.

- Pulisci l'area di lavoro: rimuovi i detriti che potrebbero ostacolare il movimento.

Posso modificare manualmente il G-code?

Sì, ma modifica solo i valori che conosci appieno e non modificare mai i percorsi utensile senza un software CAM: piccoli errori possono causare arresti anomali.

Quale software crea il G-code?

Programmi CAM: Fusion 360, Mastercam, SolidWorks CAM (a pagamento), FreeCAD, Easel (basato sul Web).

Nota: Evita di scrivere codice da zero, a meno che tu non sia esperto.

Risorse

- Documentazione LinuxCNC G-Code

- Manuale di programmazione Fanuc serie 30i/31i/32i

- Guida alla programmazione avanzata Siemens 840D SL

- Norma ISO 6983-1

- Quaderno di programmazione Haas Mill

- Manuale di programmazione CNC Mazak SmoothX

- Nozioni di base sul codice G (NRAO)

- Blog del ricettario CNC

- NC Viewer (Web, gratuito)

- CAMotics (Open source)

- Vericut

- Macchinista pratico

- Forum di LinuxCNC

- Stack Exchange – Produzione

- Reddit r/CNC