Комплексное производство металлических деталей на заказ в Китае.

Упростите свою цепочку поставок с помощью интегрированных производственных процессов, включая обработку на станках с ЧПУ, литье, ковку и многое другое.

🛡️ Весь загруженный контент хранится в безопасности и конфиденциально.

Основные возможности

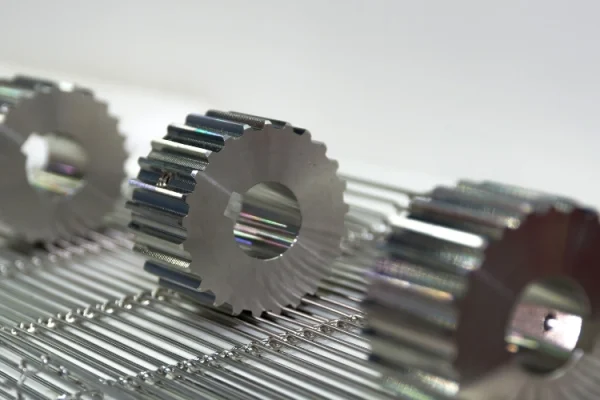

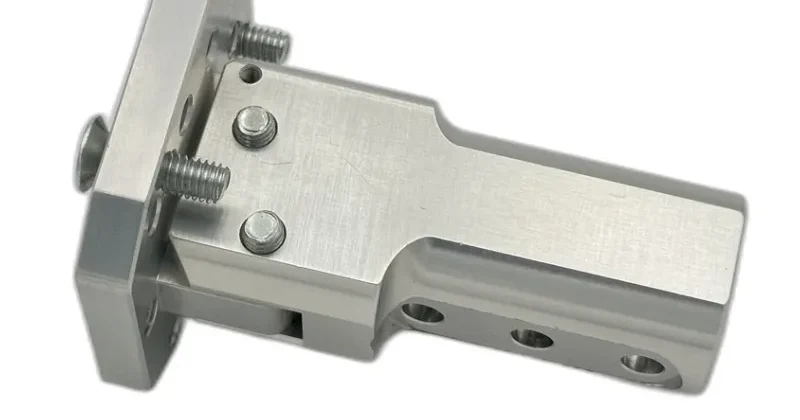

Обработка с ЧПУ

- Оборудован 3-х осевой, 4-осевой, а также 5-осевой Обрабатывающие центры с ЧПУ.

- Жесткий допуск до ±0,005 мм.

- Обработка критически важных размеров отливок и поковок на станках с ЧПУ.

- Контроль критических размеров.

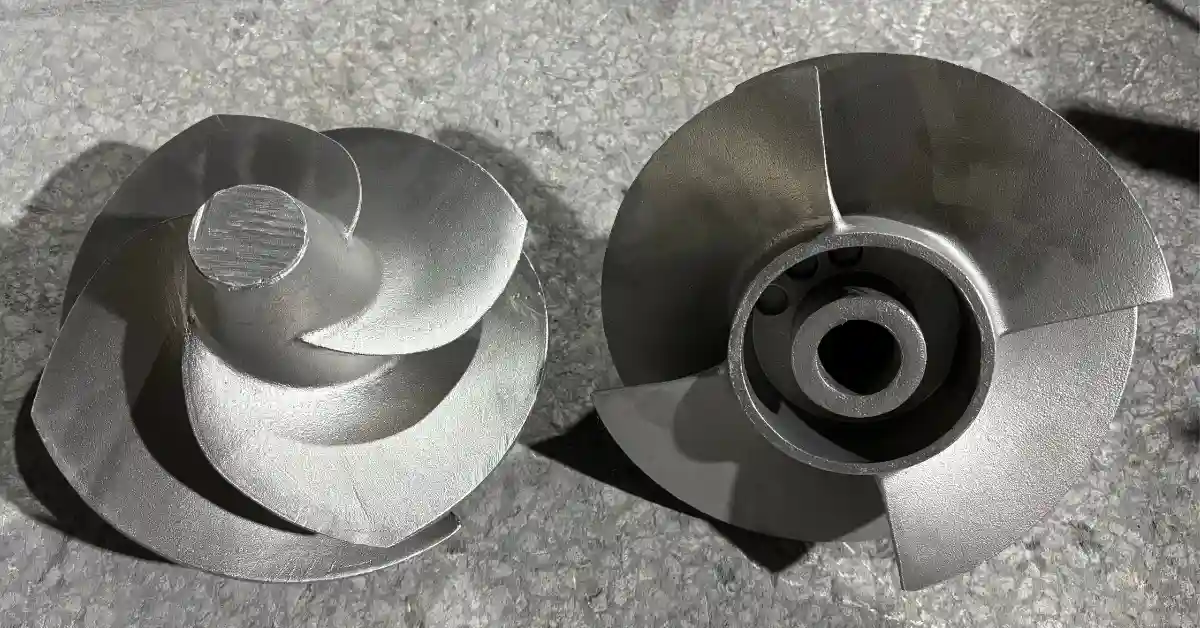

Кастинг

- Высокоточное литье с нержавеющая сталь, никелевый сплав, и многое другое.

- 50 кг максимальное количество литьевых отливок за один раз.

- Жесткая обработка с ЧПУ-станками.

- Индивидуальное решение в процессы литья, конфигурация материала, а также термическая обработка.

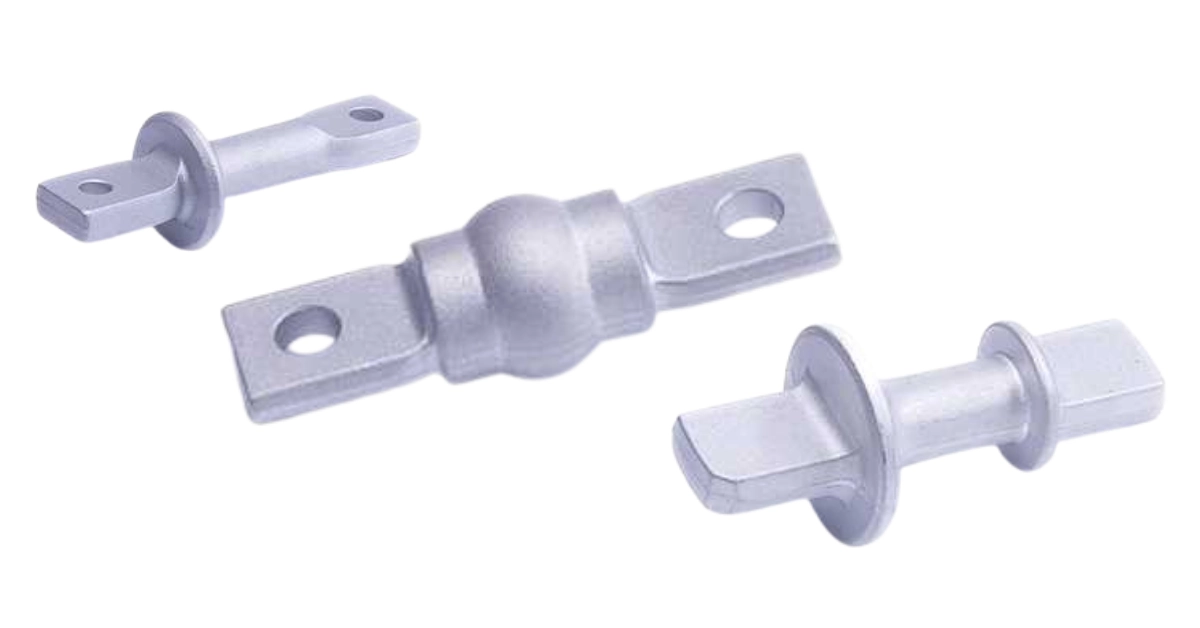

Ковка

- Ковка из алюминиевого сплава., углеродистая сталь, и нержавеющей стали.

- 30 кг максимальная одинарная ковка.

- 160Т ~ 4000Т ковочные прессы и винтовые прессы.

- Доступны методы холодной и горячей ковки.

Глобальный сервис

Мы обслужили более 1000 клиентов из более чем 50 стран.

Сертифицировано ISO и IATF

У нас есть сертификация ISO9001:2005.

50+ сертифицированных материалов

Мы можем изготовить ваши металлические детали на заказ из более чем 50 видов различных материалов.

Своевременная доставка

Детали будут доставлены вам, как и было обещано, от 1 недели до 30 дней.

Для получения более подробной информации посетите наш сайт Политика предоставления услуг страница.

Почему стоит выбрать HDC Manufacturing?

Больше, чем просто производитель: ваш партнер в области проектирования и снабжения.

Реальный проект может быть сложным и потребовать объединения нескольких производственных процессов для изготовления необходимых компонентов. Для производителей брендовой продукции управление множеством поставщиков в различных производственных процессах может быстро стать сложным и рискованным.

Начав свою деятельность как цех с ЧПУ-станками, мы постоянно расширяем свои производственные возможности и развиваем цепочку поставок, стремясь предоставлять нашим клиентам комплексные решения.

Обладая ключевыми компетенциями в области обработки на станках с ЧПУ, мы объединяем лучшие в Китае производственные ресурсы в области литья и ковки в рамках единой, надежной системы контроля качества. От проектирования и закупок до контроля качества и логистики — мы берем на себя все сложные задачи, чтобы вы могли сосредоточиться на своем продукте, а не на поставщиках.

Поднимите свой бренд на новый уровень с помощью индивидуальных решений.

В HDC Manufacturing мы выходим за рамки простого производства. Мы работаем как практичный партнер, помогая воплотить ваши идеи в жизнь. От ранних концепций до готовых компонентов, мы поддерживаем изготовление металлических деталей на заказ и прецизионную механическую обработку как для растущих, так и для уже состоявшихся брендов.

Благодаря интегрированным технологиям обработки на станках с ЧПУ, литья и ковки, мы помогаем вам работать быстрее, упрощать цепочку поставок и обеспечивать стабильное качество, чтобы вы могли сосредоточиться на развитии своего бренда, а не на управлении поставщиками.

Процесс оформления заказа

Первичная консультация

Поделитесь с нашей командой требованиями к вашему проекту. Мы рассмотрим вашу заявку и предоставим практические инженерные рекомендации, которые помогут вам начать работу.

Представление дизайна

Присылайте нам свои проектные файлы или сотрудничайте с нашими инженерами для доработки конструкции с целью повышения технологичности и экономической эффективности.

Обзор сметы и дизайна

Вы получите четкое и подробное коммерческое предложение, а также окончательную проверку всех технических характеристик перед принятием дальнейших решений.

Разработка прототипа

При необходимости мы изготавливаем прототипы для проверки конструкции, посадки и характеристик перед началом серийного производства.

Производство и контроль качества

После утверждения начинается полномасштабное производство, сопровождаемое проверками на каждом этапе и строгим контролем качества.

Доставка и доставка

Выберите предпочтительный способ доставки. Мы организуем доставку по всему миру с гарантированными сроками.

Воспользуйтесь нашими ресурсами, чтобы узнать больше о возможностях HDC.

Металлические материалы, с которыми мы работаем

Компания HDC Manufacturing работает с широким спектром металлических материалов, чтобы удовлетворить различные требования к прочности, весу и эксплуатационным характеристикам.

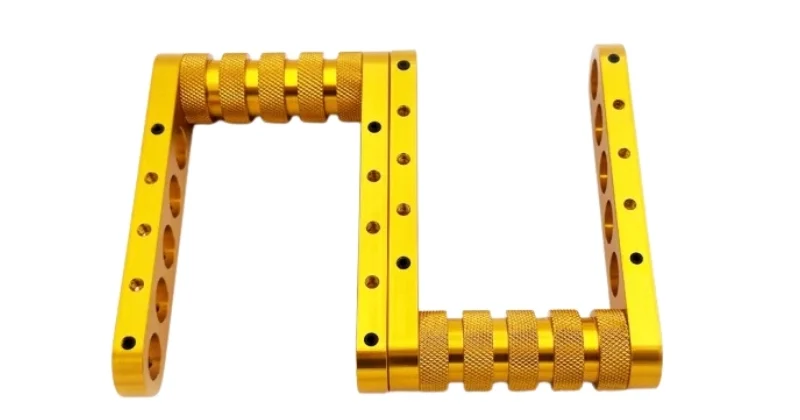

Комплексные варианты обработки поверхности

Благодаря встроенной производственной линии обработки поверхности и надежной цепочке поставок материалов для последующей обработки, компания HDC Manufacturing предлагает полный спектр услуг по обработке поверхности для улучшения внешнего вида, долговечности и функциональных характеристик металлических деталей, изготовленных на заказ.

| 🔷 Пескоструйная обработка | 🔷 Пескоструйная обработка |

| 🔷 Анодирование типа II | 🔷 Анодирование типа III |

| 🔷 Покрытие Podwer | 🔷 Живопись |

| 🔷 Цинковое покрытие | 🔷 Хромирование |

| 🔷 Лазерная гравировка | 🔷 Черный оксид |

Термическая обработка металлических деталей

Термическая обработка играет решающую роль в достижении необходимой прочности, твердости и долговечности металлических деталей.

Благодаря контролируемым процессам термической обработки и надежной цепочке поставок для последующей обработки, мы поддерживаем полный спектр вариантов термической обработки для оптимизации свойств материалов в различных областях применения.

| 🔷 Закалка | 🔷Закалка |

| 🔷 Отжиг | 🔷Нормализация |

| 🔷 Раствор для лечения |

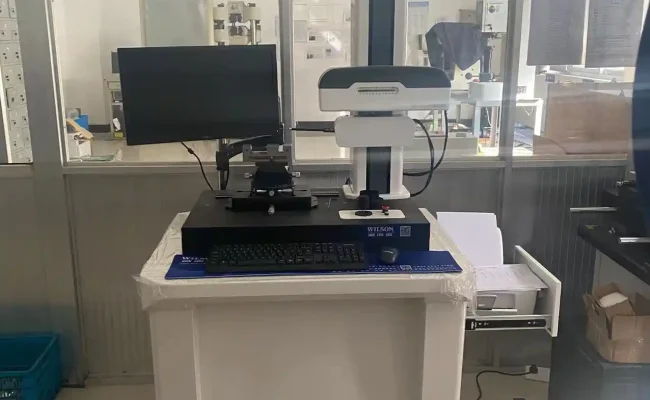

Контроль качества

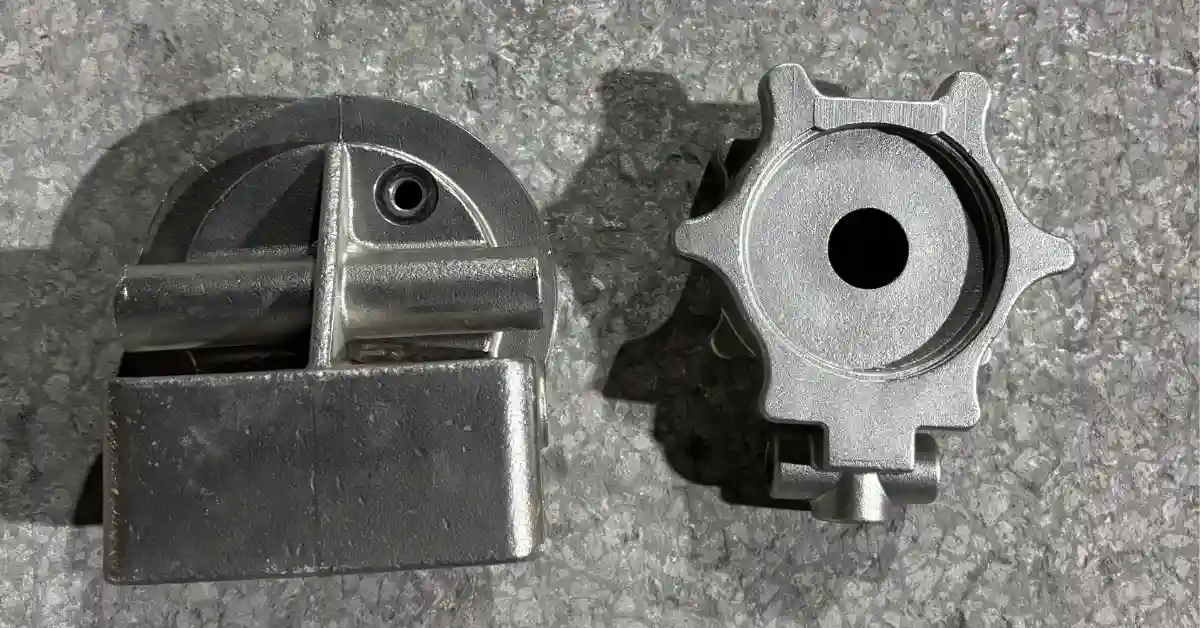

Продукция, изготовленная на заказ

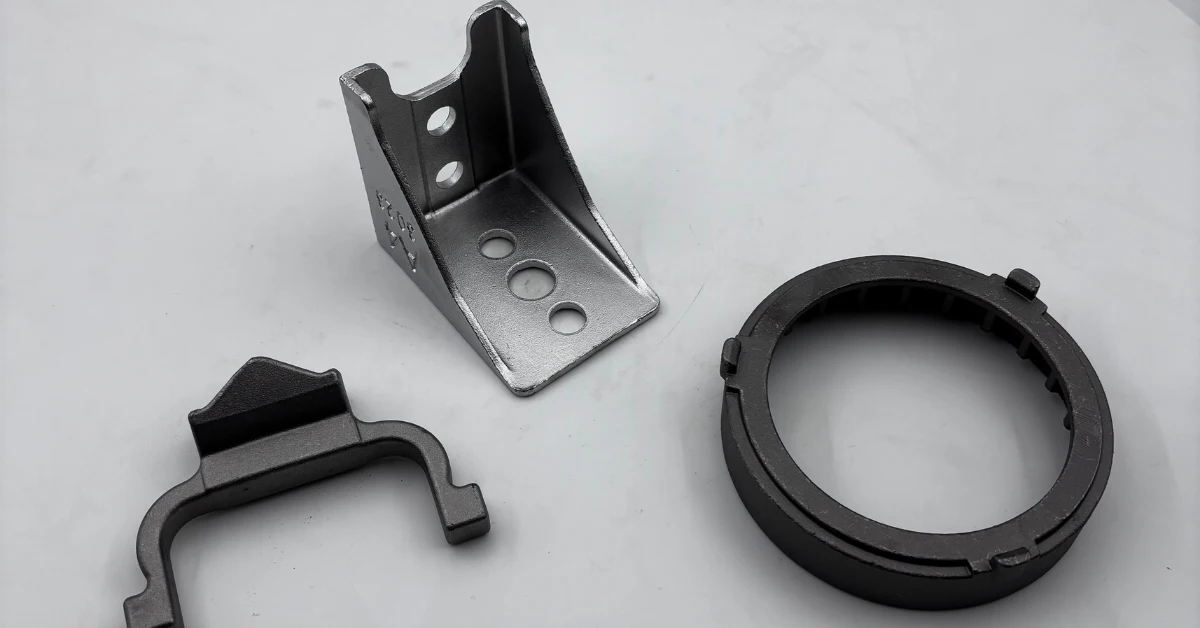

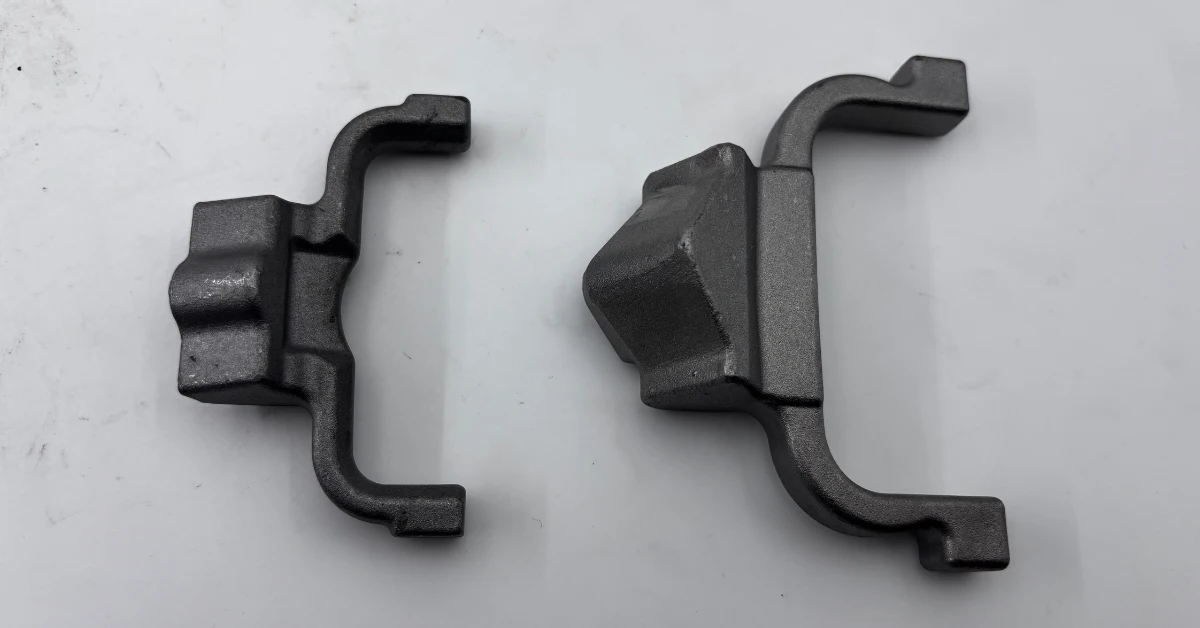

Кованые, литые и обработанные на станках с ЧПУ компоненты для различных отраслей промышленности.

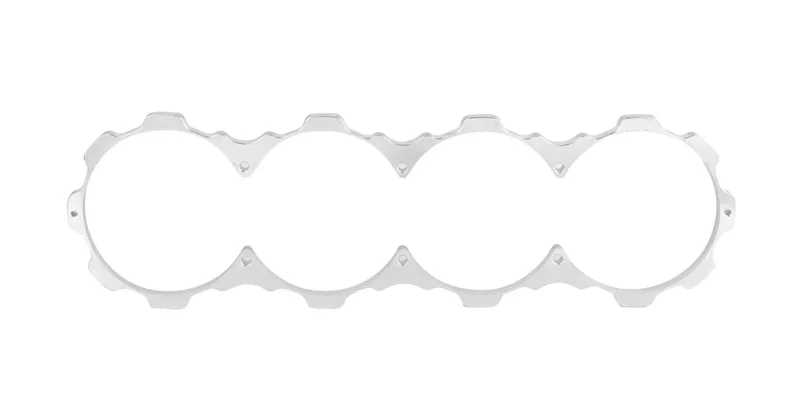

Кованые автомобильные компоненты

Кованые компоненты для мотоциклов

Аксессуары для рулевого управления и колес

Кованые конструкционные и инструментальные компоненты

Инструменты, кронштейны и фитинги

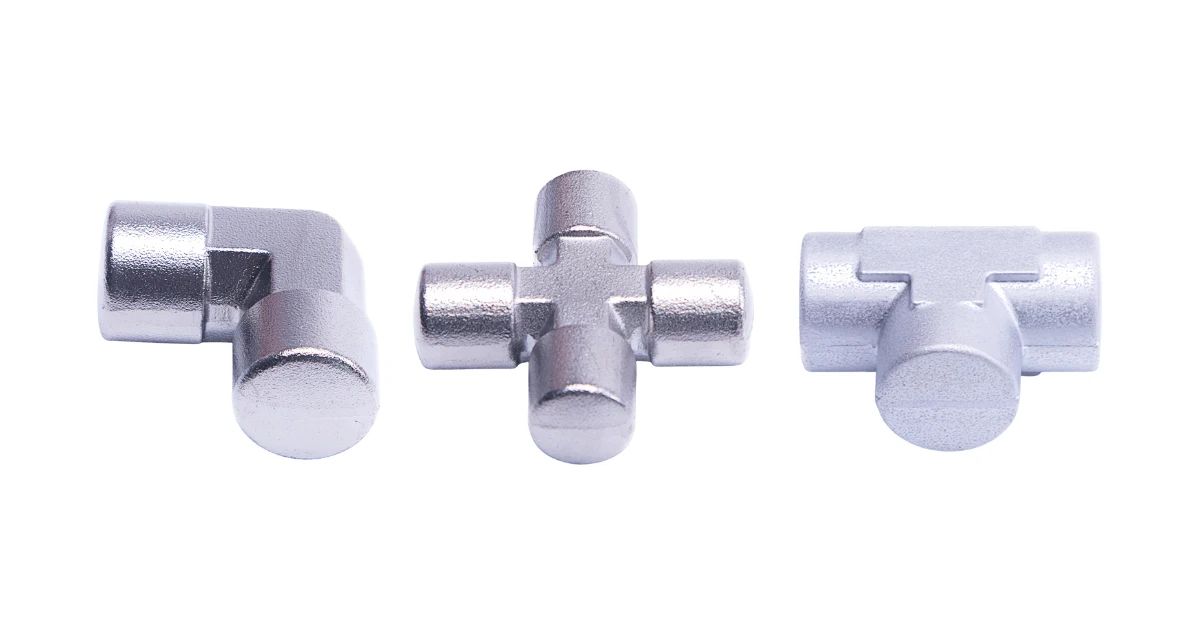

Компоненты промышленного литья

Корпус насоса, клапан, корпус редуктора

Детали литья для автомобилей

Запчасти для автомобилей, мотоциклов, велосипедов и электровелосипедов

Крепежные элементы и конструкционные отливки

Соединители, кронштейны и крепежные изделия на заказ.

Запчасти для карт с ЧПУ

Автомобильные детали с ЧПУ

Что говорят наши клиенты

Часто задаваемые вопросы

Всё, что вам нужно знать перед началом работы с компанией HDC Manufacturing.

Как мне запросить расценки?

Чтобы запросить ценовое предложение, просто предоставьте нам подробную информацию о вашем проекте, включая чертежи, требования к материалам и любые особые спецификации. Наша инженерная команда рассмотрит вашу информацию и в кратчайшие сроки предоставит четкое и подробное ценовое предложение.

Каковы типичные сроки выполнения индивидуальных заказов?

Сроки выполнения заказа варьируются в зависимости от сложности детали, количества и производственных процессов. Для большинства индивидуальных проектов производство может быть завершено в течение нескольких недель. Ориентировочные сроки выполнения заказа уточняются на этапе составления коммерческого предложения.

Какие варианты доставки доступны?

Мы предлагаем гибкие варианты доставки, включая авиаперевозки, морские перевозки и экспресс-доставку. Доставка осуществляется по всему миру, условия FOB могут быть согласованы в соответствии с вашими требованиями.

Как компания HDC Manufacturing обеспечивает качество своей продукции?

Контроль качества осуществляется на каждом этапе производства. От проверки сырья до контроля в процессе производства и окончательной инспекции, наша система качества подкреплена сертификацией ISO, что гарантирует стабильность и надежность каждого заказа.

Существует ли минимальный объем заказа (MOQ)?

Минимальный объем заказа зависит от типа продукции, материала и производственного процесса. Мы поддерживаем гибкие объемы производства и рекомендуем вам связаться с нами, чтобы обсудить наиболее подходящее решение для вашего проекта.

Может ли компания HDC Manufacturing помочь с проектированием или созданием прототипов?

Да. Мы предоставляем инженерную поддержку и услуги по созданию прототипов, чтобы помочь оптимизировать вашу конструкцию с точки зрения технологичности, производительности и стоимости перед началом серийного производства.

Какие способы оплаты вы принимаете?

Мы принимаем безопасные способы оплаты, включая банковские переводы, PayPal и другие распространенные варианты. Условия оплаты подтверждаются в процессе оформления заказа для обеспечения ясности и прозрачности.

Оказываете ли вы поддержку импортерам, впервые осуществляющим импорт?

Да. Мы регулярно работаем с импортерами, которые впервые отправляют товары за границу, и предоставляем консультации по Инкотермс, таможенному оформлению и вариантам доставки, чтобы обеспечить беспрепятственный процесс импорта.

Как я могу связаться с компанией HDC Manufacturing для получения дополнительной информации?

Связаться с нами можно через страницу контактов, по электронной почте или по телефону. Наша команда готова обсудить ваш проект и ответить на любые ваши вопросы.

Давайте воплотим ваш дизайн в жизнь!

Загрузите свои технические чертежи (STEP, IGES или PDF), чтобы получить профессиональную оценку DFM (проектирование с учетом технологичности производства) и конкурентоспособное ценовое предложение в течение 24 часов.

* Возможна техническая экспертиза. Соглашение о неразглашении может быть подписано по запросу.