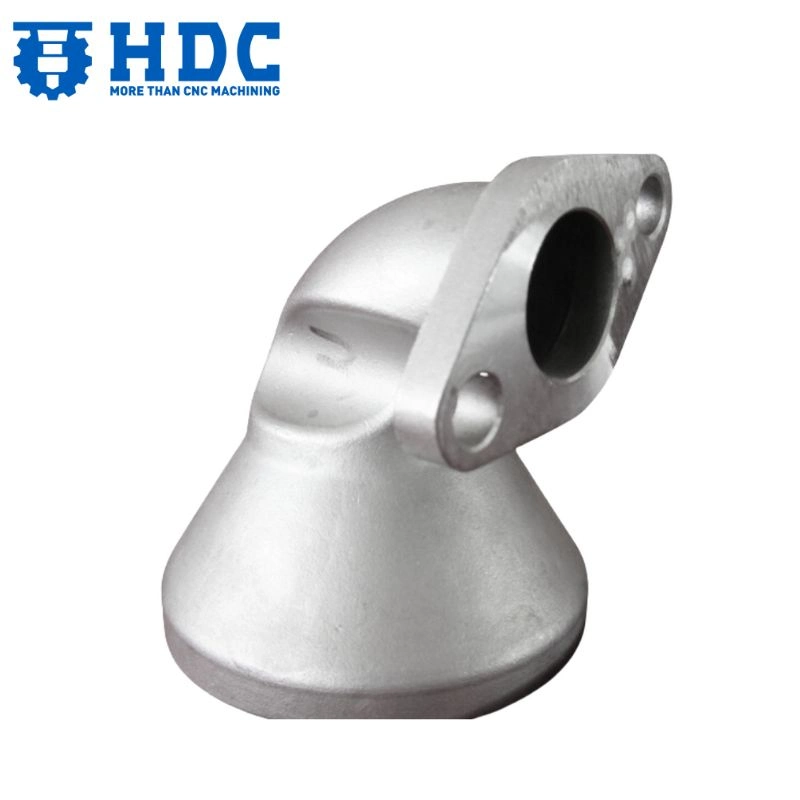

Деталь, изготовленная методом литья по выплавляемым моделям, из алюминия/стали, автомобильная деталь: вилка сцепления.

Подробная информация о товаре

| Модель №. | HDCICF001 |

| Стиль | Вилка сцепления, изготовленная методом литья по выплавляемым моделям. |

| Материал | Алюминий, алюминиевый сплав, сталь, стальной сплав, нержавеющая сталь, суперсплав, латунь |

| Тип отделки | Необработанный, полированный, анодированный, с электрофоретическим покрытием, с порошковым покрытием, оцинкованный, хромированный, с черным оксидированием |

| Доступный размер | / |

| минимальный заказ | 100 шт. |

| Пользовательский логотип | Доступный |

| Источник | Китай |

| Упаковка и доставка | |

| Вариант доставки | Курьер, воздух, море, железнодорожный экспресс, EXW, FOB, CIF, DDU, DDP |

| Дата доставки | 25-30 дней |

| Транспортный пакет | Индивидуальный, Картон, Поддон |

Achieve flawless clutch actuation and extended service life with this custom investment-cast clutch fork. Precision-engineered for drivetrains demanding complex geometry, material-specific performance, and one-piece structural integrity, this component translates release bearing force into clean, repeatable plate separation—delivered with the design freedom only investment casting can provide.

Multi-Alloy Material Optimization: Available in lightweight aluminum, high-strength steel, high-temperature superalloy, or corrosion-resistant brass—each precision-selected to match specific clutch load requirements, thermal environments, and weight reduction targets.

Investment-Cast Geometric Complexity: Precision casting enables intricate, thin-wall fork profiles, integrated pivot geometries, and optimized rib structures unattainable through conventional forging or billet machining—consolidating multiple components into a single, stress-free body.

One-Piece Structural Integrity: Eliminates welded assemblies and mechanical fasteners, removing potential failure points while reducing overall component mass and preserving continuous material properties throughout the fork architecture.

Finish-Machined Critical Surfaces: Pivot points, release bearing contact pads, and pushrod interfaces are CNC finish-machined to exacting tolerances—ensuring perpendicular engagement, consistent lever ratio, and zero free-play throughout the actuation cycle.

Long-Term Wear Resistance: Cast-in material density combined with optional localized surface hardening delivers exceptional durability at high-wear interfaces, maintaining precise engagement characteristics beyond the service life of stamped or fabricated alternatives.

Полностью настраиваемая конфигурация: Manufactured to customer-specific fork profiles, pivot styles, actuation methods (push or pull), and clearance envelopes—accommodating vintage transmissions, heavy-duty commercial applications, and high-RPM performance builds alike.

Приложения:

Performance Clutch Systems: Ideal for high-clamp-force pressure plates, multi-disc assemblies, and ceramic/metallic friction materials requiring deflection-free actuation force transmission.

OEM Replacement & Heavy-Duty Service: Essential for commercial vehicles, agricultural equipment, and high-mileage platforms demanding verified fatigue life and corrosion-resistant durability.

Vintage & Custom Drivetrain Restoration: Suitable for period-correct restorations and one-off transmission builds requiring non-standard fork geometry with modern metallurgical integrity.

More than an actuation lever, this investment-cast clutch fork is the mechanical interpreter between hydraulic or cable input and clutch pack modulation—preserving lever ratio, eliminating parasitic flex, and ensuring every disengagement is exactly when, and how, you intend. Whether you’re engineering a competition-ready drivetrain or resurrecting a classic gearbox, it’s the component that proves precision begins with cast continuity.