Stainless Steel 201: Composition, Characteristics, Naming Convention, and Applications

HDC has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your Stainless Steel 201 material components to perfection, tailored to your specific requirements.

Overview

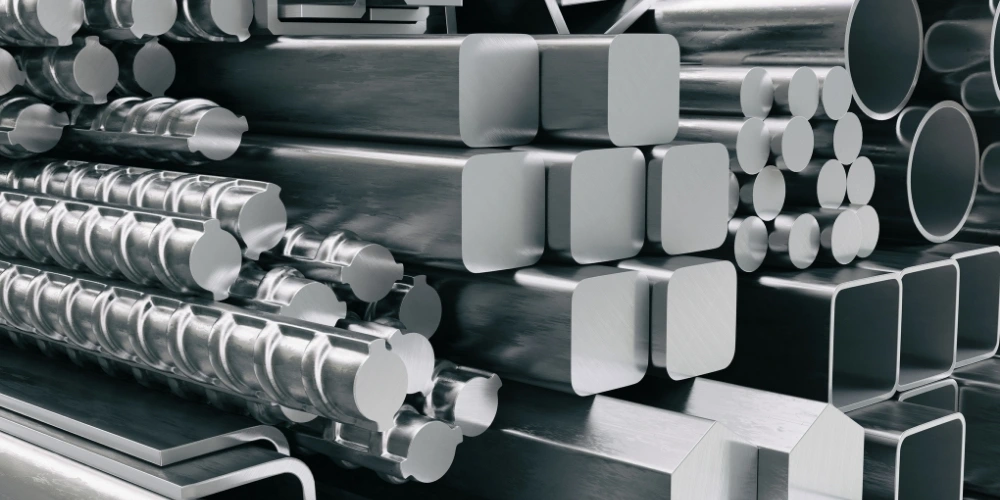

Stainless Steel 201 is an economical alternative with reasonable corrosion resistance. Its composition includes iron, chromium, and nickel, but with lower levels of chromium and nickel compared to other stainless steel grades like 304, resulting in reduced corrosion resistance. This steel is magnetic, cost-effective, and versatile. It is well-suited for indoor applications, such as kitchenware, appliances, and automotive exhaust systems, where cost is a key consideration. While it may not be suitable for highly corrosive environments, its formability and weldability make it valuable for various cost-conscious applications.

[toc]

What is Stainless Steel 201?

Stainless Steel 201 is an austenitic stainless steel alloy with nominal composition containing 18-20% of Cr element, and which demonstrates an acceptable corrosion resistance, good formability, as well as economic consideration. Consisting of Cr, Ni, Mn, and N, this grade has a good corrosion resistance suitable for much use, yet not as high as those in premium grades, such as 304 and 316. Its high shapeability makes it a good alternative to both welding and joinery in diverse industries including construction, automotive, kitchens and appliances manufacture. Nevertheless, duplex stainless steels are not suitable for extremely corrosive environments that calls for specialized stainless steels of higher grade.

Why Is This Type of Stainless Steel Named 201?

Stainless Steel 201 is named as such due to its classification within the American Iron and Steel Institute (AISI) grade system. The “200 series” stainless steels are a subset of austenitic stainless steels, and within this series, Stainless Steel 201 is specifically identified by the number “201.” This numerical designation serves to differentiate it from other stainless steel alloys and indicates its specific chemical composition and properties.

What Is the Basis for Grading Stainless Steel?

Stainless steel is graded based on its chemical composition, microstructure, and physical properties, with key elements including chromium, nickel, carbon, and various alloying elements like manganese and molybdenum. Chromium content, crucial for corrosion resistance, must be at least 10.5% for stainless steel designation. Nickel enhances corrosion resistance and adds strength, while carbon affects strength and hardness. Different series like the “200 series,” “300 series,” and “400 series” categorize stainless steel grades based on their properties. International standards organizations like ASTM and ISO provide standardized classification systems and specifications for stainless steel grades, facilitating their use across various industries and applications.

What Are the Grades of Stainless Steel?

The stainless steel grades are categorized into various series such as austenitic (300 grade), ferritic (400 grade), martensitic, duplex, and precipitation hardening stainless steels. Austenitic stainless steels like 304 and 316 provide excellent corrosion resistance and formability, while the ferritic grades such as 430 have magnetism with great corrosion resistance. The martensitic steels such as 410 have enhanced strength yet lower corrosion resistance. Duplex families of stainless steels such as 2205 have strength and excellent corrosion resistance because they are a blend of different microstructures. The hardening grades of 17-4 PH type can be heat treated to achieve the high tensile strength. These different grades have a number of properties suitable for use in different industries and they are structural, corrosion resistant, wear resistant, and can be easily worked with.

Chemical Composition of Stainless Steel 201

Element | Content (%) |

Iron, Fe | 72 |

Chromium, Cr | 16.0 – 18.0 |

Manganese, Mn | 5.50 – 7.50 |

Nickel, Ni | 3.50 – 5.50 |

Silicon, Si | 1.0 |

Nitrogen, N | 0.25 |

Carbon, C | 0.15 |

The Influence of Various Elements on the Properties of Stainless Steel 201

The characteristics of Stainless Steel 201 are dependent on the alloying elements such as chromium which confers corrosion resistance, nickel for ductility and toughness and manganese for strength. Nitrogen critical for strengthening by its presence in a material as an alloying element. Carbon, on its own, affects hardness and strength, while silicon is a scaling and oxidation resistance rising temperature ally. Yet, other minor elements like sulfur, phosphorus, and copper can be effectively used for some other purposes. 201 grade of Stainless Steel has moderate corrosion resistance, fairly good formability and mechanical properties ideally suited for different applications, where no need for more expensive stainless steels exists.

Physical Properties of Stainless Steel 201

Properties | Metric | Imperial |

Density | 7.86 g/cm3 | 0.284 lb/in³ |

Mechanical Properties of Stainless Steel 201

Properties | Metric | Imperial |

Tensile strength (transverse at room temperature) | 685 MPa | 99400 psi |

Tensile strength (longitudinal at room temperature) | 696 MPa | 101000 psi |

Yield strength (transverse at room temperature) | 292 MPa | 42400 psi |

Yield strength (longitudinal at room temperature) | 301 MPa | 43700 psi |

Compressive yield strength | 365 MPa | 52900 psi |

Elastic modulus | 197 GPa | 28573 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Elongation at break (longitudinal at room temperature) | 56% | 56% |

Elongation at break (transverse at room temperature) | 62.50% | 62.50% |

Hardness, Rockwell B (transverse at room temperature) | 85 | 85 |

Hardness, Rockwell B (longitudinal at room temperature) | 85 | 85 |

Thermal Properties of Stainless Steel 201

Properties | Metric | Imperial |

Thermal expansion co-efficient (@ 20-100°C/68-212°F) | 16.6 µm/m°C | 9.22 µin/in°F |

Thermal conductivity (@ 100°C/212°F) | 16.3 W/mK | 113 BTU in/hr.ft².°F |

Challenges Encountered in Processing Stainless Steel 201

The processing stainless steel 201 is complicated by its lower corrosion resistance, propensity for rapid cold working induced work hardening and lower machinability compared to other stainless steels. Meeting the surface finish and the formability requirements while also maintaining the economics of the materials is another point of concern. Additionally, weldability needs a correct sequence of preheating and post-weld heat treatment. Moreover, compatibility to certain environments should be evaluated in advance. Although cheap option, consideration of material properties, processing techniques, and quality control measures affect the production and must be addressed carefully.

Applications of Stainless Steel 201

Stainless steel 201 is used in different spheres thanks to its certain properties. It is a very popular material in kitchenware and kitchen appliances because of its good corrosion resistance properties and low cost, which makes it suitable for the food preparation processes. Furthermore, it is applied in the automotive components’ manufacturing including the exhaust systems and trim where the corrosion resistance and aesthetic appearance are considered. In the construction, stainless steel 201 is applied for decorative purposes and architectural trim and for structural elements, where corrosion resistance sufficiently. Along with that, its affordability permits its versatility, i.e., multiple fabrication purposes like shelves, furniture, and signage. Nonetheless, the limited use of these materials is seen in water-based or highly caustic environments where, compared to high-grade stainless steels, their serviceability is limited.

Equivalent Materials of Stainless Steel 201

EUEN | USA- | JapanJIS | FranceAFNOR |

X12CrMnNiN17-7-5 (1.4372) | 201 | SUS201 | Z12CMN17-07Az |

[toc]

Clutch Fork HDCACF001

Customized Hot Forged Aluminium Alloy Auto Clutch Release Fork Reference FOB Price: US $15.00-20.00 /Piece | 100 Pieces (Min Order.) Type: Auto Clutch Fork Samples: US$ 25/Piece Customization: Available Shipping Cost: Negotiate with us about Details. Payment Method: Get a Quote Product Details Basic Info Model NO. HDCACF001 Style Clutch Release Fork Material Aluminum, Aluminum

Control Arm HDCASA003

Aluminum Alloy Forged Auto Front Upper Suspension Control Arm Reference FOB Price: US $30.00-35.00 /Piece | 100 Pieces (Min Order.) Type: Auto Control Arm Samples: US$ 35/Piece Customization: Available Shipping Cost: Negotiate with us about Details. Payment Method: Get a Quote Product Details Basic Info Model NO. HDCASA003 Style Control Arm Material Aluminum, Aluminum Alloy,

Steering Knuckle HDCASK001

Steel Alloy Hot Forged Auto Steering Knuckle Reference FOB Price: US $25.00-30.00 /Piece | 100 Pieces (Min Order.) Type: Auto Steering Knuckle Samples: US$ 30/Piece Customization: Available Shipping Cost: Negotiate with us about Details. Payment Method: Get a Quote Product Details Basic Info Model NO. HDCASK001 Style Steering Knuckle Material Steel Alloy, Aluminum, Aluminum Alloy