About HDC Manufacturing: Our Story, Values, and Vision

Get to know HDC Manufacturing, where we combine years of expertise with cutting-edge technology to deliver unmatched quality in custom metal parts manufacturing. Learn about our journey, our values, and how we’re shaping the future of the industry.

About HDC Manufacturing

Wuxi Henderchan (HDC) Industrial Co., Ltd, also known as HDC Manufacturing, was founded in 2009. We began as a CNC machining and metal fabrication specialist, delivering high-precision components for demanding applications.

As our customers’ projects evolved, so did we. By expanding our manufacturing capabilities and trusted supply chain, HDC now provides complete custom metal manufacturing solutions, covering casting, forging, CNC machining, and finishing, all managed under a unified engineering and quality system.

Rather than focusing on a single process, HDC partners with customers to find the right manufacturing approach—supporting projects from concept to production as requirements grow.

Our Approach: One Partner, Multiple Manufacturing Routes

We believe manufacturing should follow engineering logic, not process limitations.

We start from part function, material, and volume to define the optimal path.

Combining casting, forging, and CNC to achieve precision and cost-efficiency.

Single point of responsibility from concept to mass production.

Core Manufacturing Capabilities

Casting

- Precision Investment & Sand Casting

- Stainless Steel, Alloy & Carbon Steel

- Managed scale for OEM production

- Advanced melting & material analysis

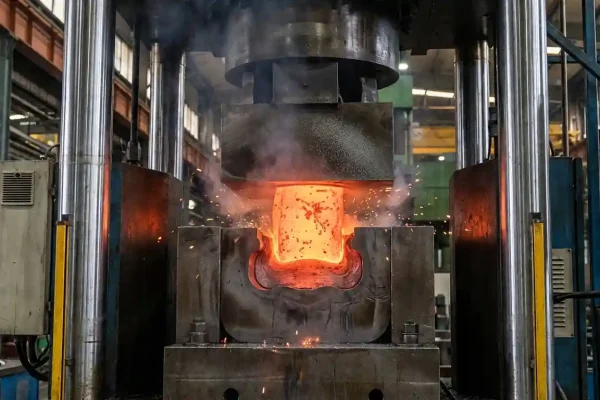

Forging

- Closed-die forging for strength-critical parts

- Press capacity from 160T to 4000T

- Improved fatigue resistance & grain flow

- Seamlessly integrated with CNC finishing

CNC Machining

- Advanced 3-, 4-, and 5-axis centers

- Tight tolerance & complex geometry

- Optimized for finishing cast/forged parts

- Single engineering workflow

Systematic Quality Assurance

Quality at HDC is a system, not just a final inspection step.

Certified Management Standards

We don’t just manufacture according to your design — we support optimization and iteration for motorsports projects.

High-Precision Metrology

Advanced CMM inspection and strict dimensional control ensure 100% alignment with your blueprints.

Material & Structural Integrity

Spectrometer analysis and NDT testing guarantee material composition and structural soundness for critical parts.

End-to-End Traceability

Full batch tracking across casting, forging, and CNC processes for total transparency and consistency.

Industries We Support

Track-tested performance parts and IATF 16949-compliant drivetrain components.

High-strength alloys and mission-critical geometries with full traceability.

Biocompatible materials and ultra-tight tolerance components for surgical devices.

Durable casting and forging solutions for heavy-duty power and infrastructure systems.

Our Journey

From Precision Machining to Integrated Manufacturing Solutions

HDC Manufacturing was founded in Wuxi, focusing on establishing excellence in custom CNC machining.

2009

Ventured into Motorsports (Cars, Motorcycles, Karting). Expanded into 5-axis machining to handle high-performance geometries.

2010 - 2012

Introduced CMM inspection and achieved ISO 9001 certification, standardizing production for Marine and Aerospace clients.

2014 - 2016

Added laser cutting, punching, and professional welding. Transitioned from "part supplier" to "assembly component provider".

2019

Relocated to advanced facilities with high-end 5-axis centers. Fully integrated managed Casting & Forging into our one-stop supply chain.

2021 - Present

Let’s Build the Right Manufacturing Solution

Have a complex part or a growing project?