- Home

- Capabilities

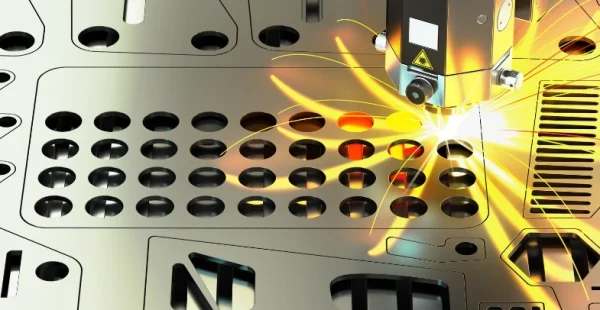

- Laser Cutting Service

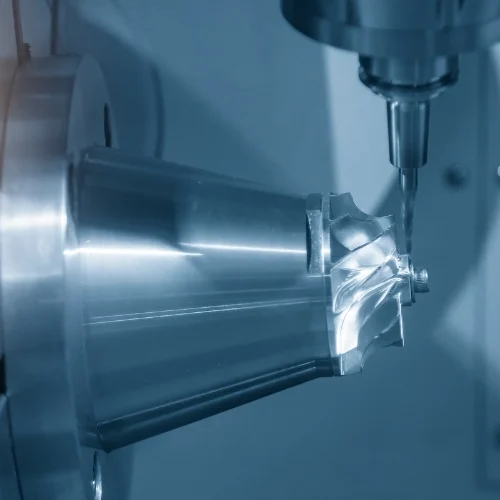

Professional Laser Cutting Services Provide By HDC

HDC delivers expert laser cutting services, combining state-of-the-art technology with unparalleled precision and efficiency to meet your exact specifications.

Advantages of Laser Cutting Technology

Discover the unparalleled benefits of laser cutting for precise, efficient, and versatile manufacturing solutions.

Why Choose HDC Laser Cutting Service

At HDC, we combine state-of-the-art laser cutting machines and a skilled team to deliver precise, high-quality cuts for large-volume and complex orders. Our advanced technology minimizes material waste, reducing costs and environmental impact, while our competitive pricing ensures cost-effective solutions without compromising quality. We handle a wide range of materials, including metals like steel, aluminum, and titanium, meeting both specialized and common needs.

Our strict quality control ensures every piece meets the highest standards, consistently exceeding expectations. From initial consultation to after-sales support, our dedicated team provides exceptional customer service, ensuring your project’s success. Choose HDC Laser Cutting Service for unparalleled precision, quality, and efficiency, and let us help you achieve your manufacturing goals with excellence.

Materials Used in Laser Cutting

Explore the diverse range of materials that can be precisely cut with our advanced laser cutting technology.

Highly resistant to rust and corrosion, commonly used in medical devices, kitchen equipment, and outdoor structures. Laser cutting ensures smooth, burr-free edges, critical for applications requiring high hygiene standards.

Lightweight and corrosion-resistant, perfect for aerospace, automotive, and architectural projects. Its excellent strength-to-weight ratio makes it ideal for parts where weight reduction is crucial.

Ideal for structural components, machinery parts, and industrial applications due to its strength and durability. Laser cutting allows for precise and clean edges, making it suitable for high-stress environments.

Known for its high strength-to-weight ratio and biocompatibility, often utilized in aerospace, medical implants, and high-performance engineering. Laser cutting allows for intricate designs and precise tolerances necessary for these advanced applications.

Versatile and easily shaped, used in signage, displays, electronic housings, and consumer products. Laser cutting provides clean cuts without melting or warping, maintaining the integrity of the material.

Exploring Laser Cutting

Delve into the intricate world of laser cutting, understanding its processes, techniques, and the diverse applications it supports in various industries.

Laser cutting involves focusing a high-power laser beam onto the material’s surface, melting, burning, or vaporizing it along the desired path. A computer-controlled system directs the laser for precision and accuracy. Since its inception in the 1960s, laser cutting technology has significantly evolved. Initially developed for industrial applications, it has advanced with improvements in laser power, precision, and control systems. Modern laser cutting machines now utilize sophisticated software and high-powered lasers to deliver unparalleled accuracy and efficiency, making them indispensable in various industries.

Types of Laser Cutting:

There are three main types of laser cutting used today:

- CO2 Lasers: Ideal for cutting, boring, and engraving non-metallic materials such as wood, acrylic, and glass. CO2 lasers are widely used due to their efficiency and cost-effectiveness.

- Fiber Lasers: Known for their high cutting speeds and precision, fiber lasers are particularly effective for cutting metal materials, including steel, aluminum, and brass. They offer superior performance in terms of speed and energy efficiency.

- Nd:YAG Lasers: These lasers are suitable for high-power applications and can cut both metals and non-metals. Nd:YAG lasers are often used in industrial and medical settings for tasks requiring high precision and depth.

Precision and Accuracy:

Laser cutting is renowned for its precision, capable of cutting materials with tolerances as tight as 0.001 inches (0.025 mm). This high level of accuracy is crucial for applications requiring intricate details and complex geometries, such as aerospace components, medical devices, and electronic parts.

Materials Thickness:

Lasers can cut very thin materials (down to micrometers in thickness) with extreme precision. Laser cutting is also capable of cutting thicker materials (up to several centimeters), though the quality and speed can be affected by the material’s properties.

Edge Quality: The quality of the cut edge depends on factors such as the material type, thickness, laser power, and cutting speed. Proper settings and adjustments can achieve smooth, clean edges with minimal post-processing required.

Diverse Applications of Laser Cutting

Laser cutting is used in the automotive sector to produce a range of parts, including body panels, exhaust systems, and intricate decorative trims. Its precision and efficiency help in creating high-performance and aesthetically pleasing automotive components.

In the aerospace industry, laser cutting is employed to manufacture lightweight and high-strength components such as airframe structures, turbine blades, and intricate brackets. The precision and minimal material waste are crucial for the performance and safety of aerospace parts.

Aerospace

In architecture and construction, laser cutting is used to create custom decorative elements, metal frameworks, and intricate design features. Its precision and versatility allow for the production of unique architectural components.

For the electronics industry, laser cutting is utilized to create detailed and precise electronic enclosures, circuit boards, and components. The ability to handle small and intricate parts makes laser cutting ideal for electronics manufacturing.

This sector uses sheet metal in the production of large-scale energy systems, including wind turbines and solar panel frames. Sheet metal's robustness and weather resistance are essential for enduring the rigors of outdoor energy applications.

In the medical field, laser cutting is essential for producing precise and sterile components such as surgical instruments, implants, and medical device parts. The high accuracy and cleanliness of laser cuts meet the stringent standards required in medical applications.

Medical Devices

Laser cutting is popular in the signage and advertising industry for creating custom signs, letters, and intricate designs from materials like acrylic and plastics. The ability to produce detailed and polished finishes makes laser-cut signs highly appealing.

Precision of Laser Cutting

Discover the exceptional accuracy and precision capabilities of laser cutting technology.

| Precision Aspect | Description |

| Dimensional Tolerance | ±0.1 mm or better, ensuring high accuracy for detailed and complex parts. |

| Edge Quality | Smooth and clean edges with minimal to no burrs, reducing the need for further finishing. |

| Kerf Width | As narrow as 0.1 mm, allowing for intricate and delicate designs. |

| Repeatability | Consistent precision across multiple cuts, essential for mass production. |

| Minimum Feature Size | As small as 0.2 mm, enabling the creation of fine details in parts. |

| Material Thickness | Capable of accurately cutting materials from thin sheets up to several centimeters thick. |

| Heat-Affected Zone (HAZ) | Minimal HAZ, preserving material properties and preventing distortion. |

| Cutting Speed | High-speed cutting while maintaining precision, boosting overall efficiency. |

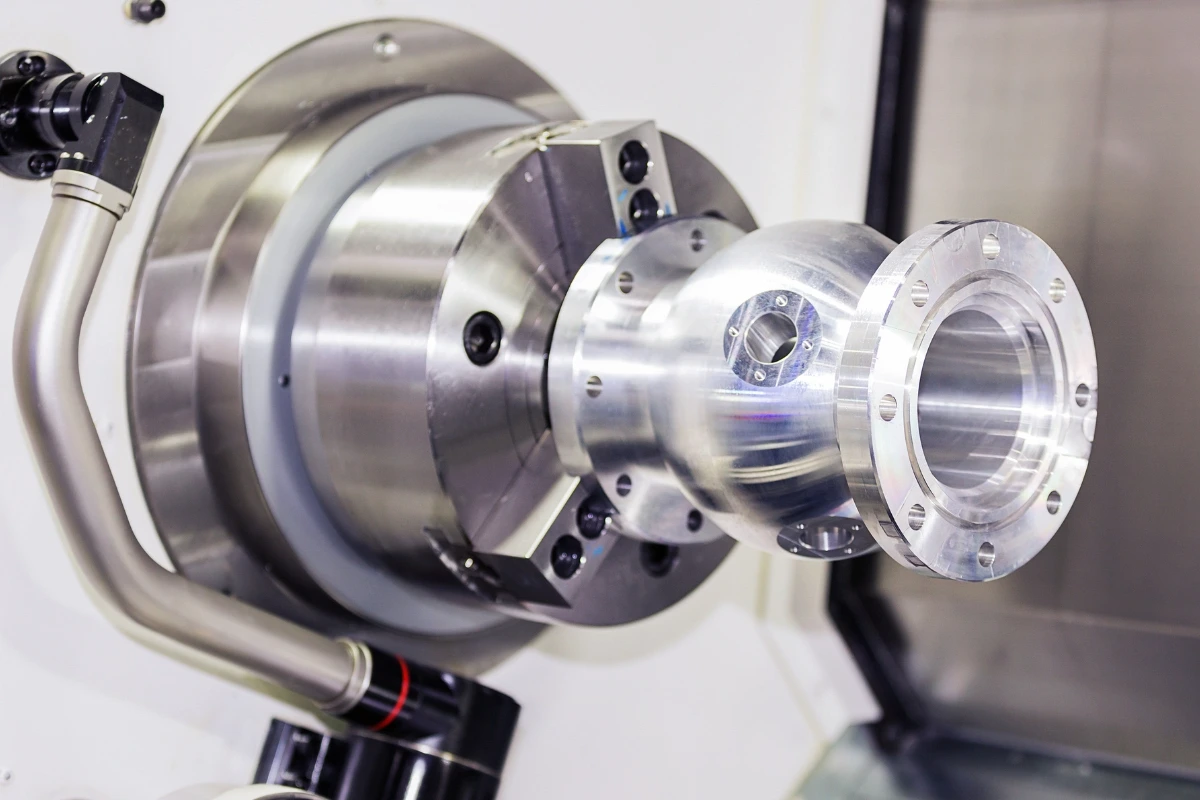

Processing Capabilities of Laser Cutting at HDC

Precision Engineered for Optimal Performance

At HDC, we pride ourselves on delivering top-notch laser cutting services that meet diverse industrial needs. Our advanced capabilities include:

- High Precision: Our laser cutting machines achieve tolerances as tight as ±0.1 mm, ensuring exact and intricate cuts for complex designs.

- Wide Material Range: We handle a variety of materials, including metals (steel, aluminum, titanium) and non-metals (wood, acrylic, plastic).

- Large Cutting Area: Our machines support large-format cutting up to 3000 mm x 1500 mm.

- High Speed: Efficient cutting speeds enhance productivity without sacrificing quality.

- Advanced Software Integration: Compatible with most CAD and design software, ensuring seamless project integration.

Whether you need prototypes, large production runs, or custom parts, HDC’s laser cutting capabilities provide the precision and reliability required for your projects.

Laser Cutting Service FAQ

Find answers to common questions about our laser cutting services to help you make informed decisions for your projects.

Our laser cutting technology can handle a wide range of materials, including metals (steel, aluminum, titanium), non-metals (wood, acrylic, plastic), and composites.

Our machines can cut materials up to several centimeters thick, depending on the material type. Please contact us for specifics regarding your material.

Laser cutting achieves high precision with tolerances as tight as ±0.1 mm, ensuring detailed and accurate cuts for complex designs.

We accept various file formats, including DXF, DWG, AI, and PDF. If you have a different format, please let us know, and we will do our best to accommodate.

Turnaround time varies based on the project's complexity and volume. Typically, small to medium-sized orders can be completed within a few weeks. Please contact us for a more accurate estimate based on your specific project.

Yes, we offer design assistance and prototyping services to help you refine your ideas and ensure they are optimized for laser cutting.

Laser cutting offers high precision, minimal waste, versatility in material usage, and faster production times compared to traditional cutting methods.

Simply contact us with your project details, including material specifications, design files, and any special requirements. Our team will provide you with a quote and guide you through the process.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!