Enhancing Vehicle Performance with CNC-Machined Clutch Covers

Explore the pivotal role of CNC-machined clutch covers in vehicle performance. This article details the design, functionality, and benefits of CNC clutch covers, highlighting how they protect the clutch assembly from external contaminants, enhance vehicle aesthetics, and contribute to optimal transmission functionality. Dive into the various materials and customization options available, and learn how CNC technology delivers precision and adaptability in clutch cover manufacturing.

Understanding CNC Clutch Cover

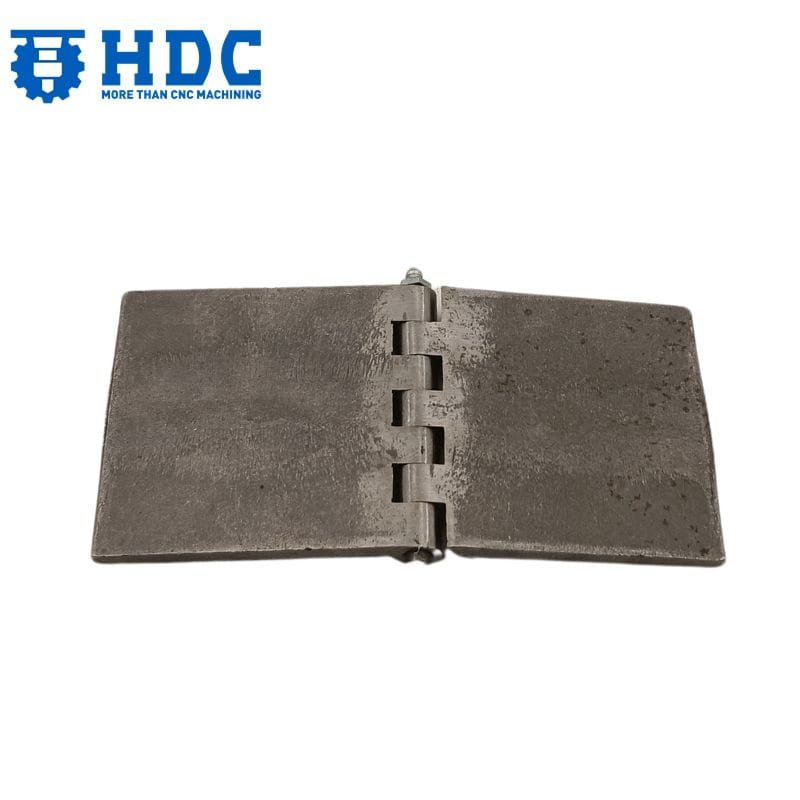

A CNC clutch cover, often referred to as a CNC-machined clutch cover, is a component used in the clutch system of a vehicle, typically a motorcycle or an off-road vehicle like an ATV or dirt bike. The clutch cover is a protective casing that encloses and protects the clutch assembly, which includes the clutch plates, pressure plate, and other related components.

The term “CNC” in CNC clutch cover stands for “Computer Numerical Control,” which refers to the method of machining or manufacturing the cover.

Primary Function of a Clutch Cover

A clutch cover is a protective component that encases and shields the clutch assembly in a vehicle, typically found in manual transmission vehicles, such as motorcycles. The clutch cover, also known as a clutch housing or clutch casing, is designed to protect the clutch from dirt, debris, and external elements that could potentially damage or affect the operation of the clutch. In addition to providing protection, the clutch cover also helps contain the clutch components and ensures that they function properly within the transmission system. It’s an essential part of a vehicle’s drivetrain that helps maintain the integrity and performance of the clutch.

Different Types of Clutch Covers

A clutch cover’s primary function is to safeguard and enclose the clutch assembly within a vehicle’s transmission system, shielding it from external contaminants and potential damage. It enhances safety by preventing foreign objects from interfering with the clutch operation, ensures proper containment of clutch components, reduces dust and noise, and may include features for heat dissipation. Some clutch covers also serve aesthetic and branding purposes, allowing vehicle enthusiasts to customize the appearance of their vehicles.

The Impact of Clutch Cover on Automotive Performance

The clutch cover itself does not significantly affect the performance of a vehicle’s clutch system. Its primary function is to protect and encase the clutch assembly, as well as to reduce dust and noise. However, in some cases, aftermarket clutch covers may be designed with specific features, such as cooling fins or materials that help dissipate heat more effectively, which can have a marginal impact on clutch performance by helping to maintain optimal operating temperatures. Generally, the performance of the clutch system is more directly influenced by factors such as the quality of the clutch components (clutch plates, pressure plate, etc.), the clutch’s adjustment, and the skill of the rider in using the clutch effectively.

Materials Typically Used in Manufacturing CNC Clutch Covers

CNC clutch covers are generally made from various materials selected for their specific properties and performance attributes. The commonly used materials are steel is for strength and robustness, aluminum is to reduce weight and heat dissipation, cast iron results in wear resistance, magnesium provides lightweight performance gains; reinforced plastics or carbon fiber composites provide a balance of strength reduction in weight some with high-temperature resistance. The selection of the material is determined by factors like vehicle application, horsepower, and operating conditions which allows manufacturers to customize the clutch cover for desired purposes.

Finishing Options Available for CNC Clutch Covers

- Polishing: This process produces a glossy and polished surface that not only makes the clutch cover visually pleasing but also ensures that it lasts for an extended period.

- Anodizing: They further increase the resistance to corrosion and can also be coloured in various color options for a customized look.

- Powder Coating: The powder coating is long-lasting and offers varied color choices to shield and accessorize the clutch cover.

- Painting: High-end custom paint finishes offer the opportunity to create complex designs, logos or branding on clutch covers.

- Bead Blasting: This method generates a mat or textured with enhanced appearance for the clutch cover.

- Natural or Bare Metal: Some clutch covers remain untreated in order to retain their raw industrial appearance.

The selection of finish type relies on the desired look, performance specifications, and customization desires for the CNC clutch cover.

CNC Technologies Primarily Used to Manufacture CNC Clutch Covers

CNC technologies are key to producing CNC clutch covers encompassing precision and uniformity throughout the manufacturing process. These technologies include machining operations, such as milling, drilling, and turning that cut out the clutch covers with high precision. Milling forms complex contours, drilling produces high accuracy holes and turning guarantees the required smoothness as well as concentricity.

In addition, CNC technologies provide a wide range of customization capabilities that enable manufacturers to tailor clutch cover designs to fit specific requirements and uses. This flexibility, in conjunction with CNC’s accuracy and repeatability, generates clutch covers that conform to industry standards molded for a wide range of automotive and industrial applications. In essence, CNC technologies have allowed clutch cover manufacturing to reach unrivaled levels of accuracy and adaptability.

Clutch Covers are Typically Not Universal

Clutch covers, also called pressure plates are semi-standard because of industry standards as well as the aftermarket availability. They are designed to provide pressure on the clutch disk for engagement and disengagement of transmission, which is a core part of manual transmissions in many cars. Although many clutch covers are manufactured according to some specifications and can be interchangeable or compatible with almost all vehicles, the compatibility may still vary depending on particular make/model of a vehicle and its engine, which is why it’s so important to find the best fitting clutch cover yourself.

Customizing Small Batches of CNC Clutch Covers Is More Cost-Effective

While small batches of CNC clutch covers can be more cost-effective in certain situations, it depends on factors such as setup costs, material costs, labor costs, and the specific requirements of the project. It’s essential to evaluate the overall costs and benefits of small-batch customization based on your unique needs and objectives. In some cases, small-batch customization may be the best approach, while in others, economies of scale may make larger production runs more cost-effective.

Customize CNC Clutch Covers

CNC clutch covers are customized to individual needs through a complicated procedure. Start by specifying your requirements (materials and dimensions) and find a credible CNC machining manufacturer. Call them, give details on your design and ask for a complete quote that fits your budget. Work together with their engineering team to perfect the design and choose appropriate materials. Alternatively, think of a prototype to test before production.

After the design is approved, the manufacturer will adopt CNC machining to guarantee quality control in their production. Check the finished clutch covers for accuracy and characteristics. Talk about packaging and shipping, make all payments, as well as keep records of all transactions. Lastly, install the custom clutch covers in your application and test them to make sure they fit your specifications. Communication and cooperation with the manufacturer play an important role in a successful customization process.

Conclusion

CNC clutch covers play a crucial role in ensuring the smooth operation of vehicles and machinery. Understanding their functions, types, and customization options is essential for making informed choices. Whether you’re a mechanic, enthusiast, or simply curious about these components, this article has provided you with valuable insights.

Resources:

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!