High Performance Front Wheel Bearings & Spindle Bearings

Reference FOB Price:

US $3.00-10.00

/Piece | 100 Pieces (Min Order.)

Type:

Go Kart Wheel Bearing

Samples:

US$ 30/Piece

Customization:

Available

Shipping Cost:

Negotiate with us about Details.

Payment Method:

Product Details

Basic Info

| Model NO. | HDCKB003 |

| Style | Double Seal Ball Bearing |

| Material | Bearing Steel |

| Finish Type | / |

| Available Size |

|

| MOQ | 100 |

| Custom Logo | Available |

| Origin | China |

Packaging & Delivery | |

| Shipping Option | Courier, Air, Sea, Railway Express, EXW, FOB, CIF, DDU, DDP |

| Delivery Date | 25-30 days |

| Transport Package | Customized, Carton, Pallet |

| Available Specifications (Customizable) | |||||

| 8 x 22 x 7 (mm) | 10 x 22 x 6 (mm) | 10 x 26 x 8 (mm) | 12 x 28 x 8 (mm) | 15 x 35 x 11 (mm) | 17 x 35 x 10 (mm) |

| Wheel Bearing Standard Specifications (Customizable) | |||

| Fits For | I.D. | O.D. | Width |

| 17mm Spindle | 17mm | 35mm | 10mm |

| 25mm Spindle“OTK Size” | 25mm | 42mm | 12mm |

| 25mm Spindle “all others” | 25mm | 42mm | 9mm |

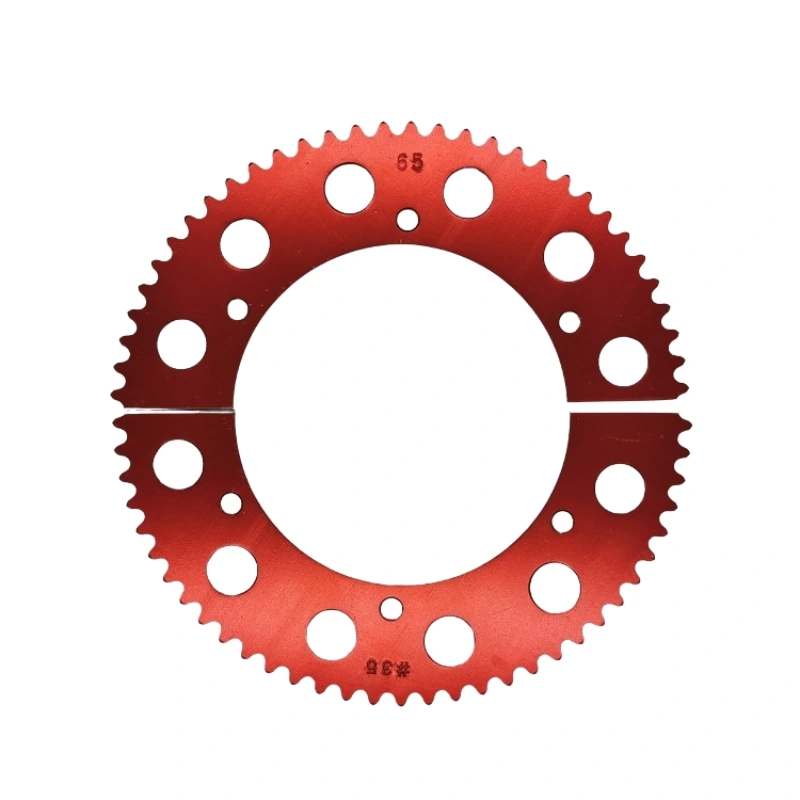

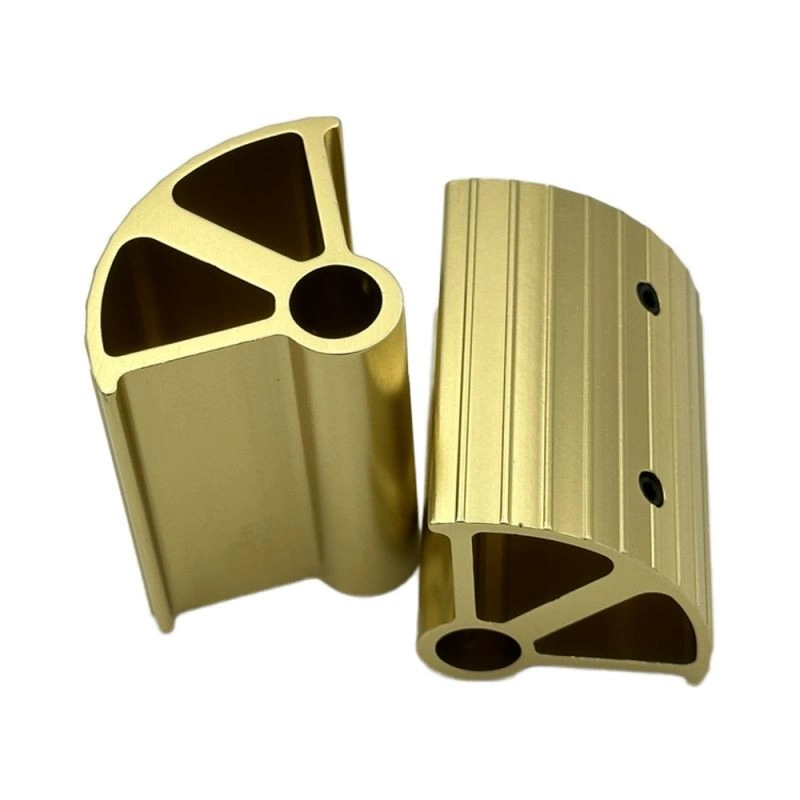

Key Features

- Material: Crafted from premium stainless steel for maximum strength and corrosion resistance.

- Sealing: Double seal configuration offers superior protection against contaminants.

- Size: Universal fit with an inner diameter of 5/8 inch and outer diameter of 1-3/8 inch, compatible with most go-kart front wheel hubs.

- Durability: Designed to endure the harsh conditions of kart racing and recreational use.

- Performance: Ensures smooth wheel operations and reduces maintenance needs.

Applications:

- Racing Karts: Ideal for competitive go-kart racing, providing reliable and long-lasting wheel performance.

- Recreational Go-Karts: Perfect for leisure applications, enhancing the driving experience with dependable wheel rotations.

- Custom Go-Kart Builds: A must-have component for DIY go-kart enthusiasts looking to build or upgrade their karts with high-quality bearings.

This Stainless Steel Double Seal Ball Bearing is an essential upgrade for any serious go-kart builder or racer aiming for top performance and durability in their wheel assemblies.