- Home

- Capabilities

- Welding Service

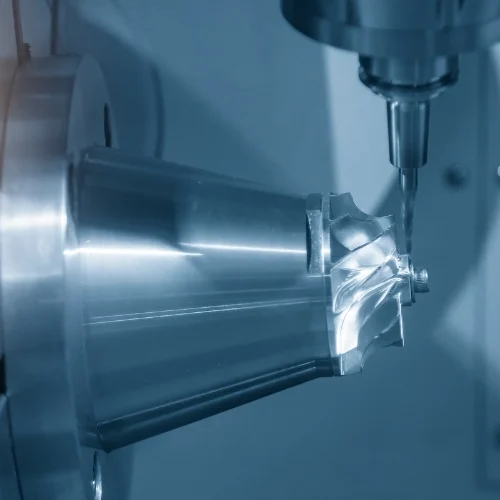

Expert Welding Services for Custom Metal Solutions

Welding quality directly impacts project success. HDC offers exceptional welding solutions to ensure you achieve the best results.

Why Choose HDC Welding Services

HDC’s welding services combine high-quality materials and professional techniques, providing clients with reliable custom metal products that ensure project success. Our skilled technicians are well-versed in the latest welding technologies, offering a range of processes including MIG and TIG welding tailored to your specific requirements. This versatility allows us to handle projects of any size and complexity, guaranteeing optimal results every time.

At HDC, we adhere to strict quality assurance protocols throughout the welding process, with each project undergoing comprehensive inspections to ensure compliance with international standards. Our commitment to quality not only enhances the performance of our products but also fosters long-term trust with our clients. By choosing HDC welding services, you gain access to high-quality custom solutions that guarantee the success and satisfaction of your projects.

Advantages of HDC Welding Service

Explore the unique advantages that set HDC's welding services apart from the competition.

Materials Compatibility in Welding Services

Learn about the diverse range of materials we can weld to meet your project requirements.

Steel

When welded, steel offers good tensile strength and toughness, making it ideal for structures that need to withstand heavy loads. Its ease of welding and relatively low cost make it a go-to choice for many applications, from bridges to industrial equipment.

Aluminum

Aluminum welding capabilities allow for strong joints while keeping weight down, which is essential for applications requiring reduced mass without sacrificing structural integrity. While welding aluminum does require specialized equipment and techniques, its benefits far outweigh the challenges.

Stainless Steel

Stainless steel maintains a smooth surface when welded, making it easy to clean and maintain. Its resistance to oxidation also ensures outstanding performance in humid environments, making it the material of choice for many demanding applications.

Our Welding Capability: TIG Welding & MIG Welding

Understand our expertise in both TIG and MIG welding techniques for various applications.

At HDC, we’re proud to offer a wide range of welding services designed to meet your unique needs. Our talented welders are experienced in various techniques, including:

- MIG Welding: This method is celebrated for its flexibility and speed. MIG welding is great for joining aluminum, stainless steel, and other metals. With our advanced MIG welding machines, we ensure high-quality results whether you’re working with thick or thin materials.

- TIG Welding: When precision matters most, TIG welding is the way to go. It provides a clean finish and is especially effective for aluminum. Many industries, including aerospace and automotive, rely on this technique for its meticulous results.

No matter the scope of your project—be it a simple repair or a complex fabrication—we have the expertise and equipment to handle it. Our welders are committed to delivering outstanding results that go beyond your expectations.

Our Welding Process: Step-by-Step Guide

Get an overview of our streamlined welding process, from consultation to project completion.

1. Initial Consultation

2. Design Review

3. Material Selection

4. Quote and Approval

5. Welding Process

6. Quality Control

7. Final Inspection and Delivery

Industries We Serve

Find out the different industries that benefit from HDC's custom welding services.

Transportation Industry

Aerospace Industry

Construction Industry

FAQs

Access answers to frequently asked questions about our welding services and processes.

HDC specializes in MIG and TIG welding, allowing us to cater to a wide range of projects and materials, ensuring high-quality results tailored to your needs.

We can weld various materials, including aluminum, stainless steel, carbon steel, and more. Our team will guide you in selecting the best material for your specific project.

The timeline for a welding project depends on its complexity and size. During the initial consultation, we’ll provide an estimated completion time based on your requirements.

We adhere to strict quality assurance protocols, conducting thorough inspections at each stage of the welding process to ensure compliance with industry standards.

Absolutely! We specialize in custom welding services and can tailor our approach to meet the unique specifications of your project.

You can request a quote by contacting us directly through our website or by phone. Please provide details about your project, and we’ll respond promptly.

We welcome specific design requests and will work closely with you to ensure that your vision is accurately realized in the final product.

We do not have a strict minimum order quantity, but larger projects may benefit from better pricing and efficiency. Feel free to discuss your needs with us.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!