Aluminum is a popular material and has a wide range of alloys, among which 6063 aluminum is also one. It is used in many industries but architectural applications are highly dependent on it. If you are looking forward to learning in detail about 6063 aluminum, the guide below can help you. So, let’s read.

Chemical Composition of 6063 Aluminum

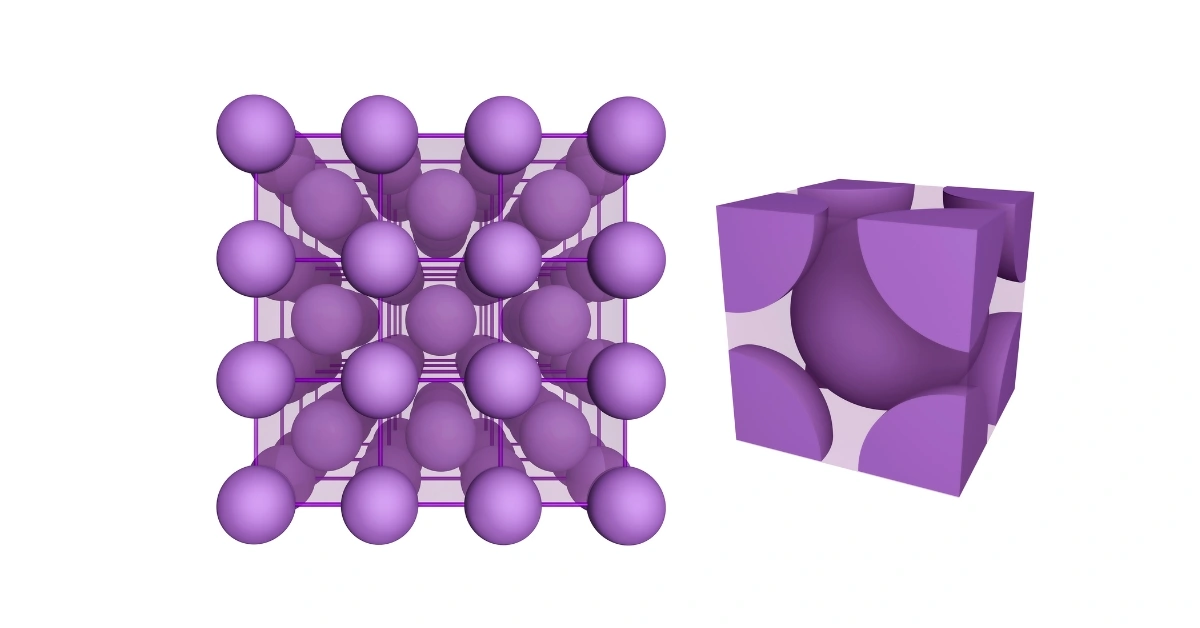

6063 aluminum is manufactured after alloying aluminum with multiple other elements in different quantities. The properties of each of the alloy elements are composed in aluminum 6063, making it suitable for different uses. The composition of 6063 aluminum comprises the following elements.

- Aluminum – 97.9% to 99.6%

- Silicon – 0.2% to 0.6%

- Copper – less than 0.1%

- Magnesium – 0.45% to 0.9%

- Iron – less than 0.35%

- Manganese – less than 0.1%

- Zinc – less than 0.1%

- Titanium – less than 0.1%

Properties of 6063 Aluminum

6063 aluminum is divided into three categories when it comes to its properties, and each plays a vital role in deciding where to use it. A detailed insight into its chemical, physical, and mechanical properties is as follows:

Chemical Properties:

- It contains primary alloying elements composed of aluminum, silicon, and magnesium.

- Aluminum 6063 offers excellent corrosion resistance as it has a layer of aluminum oxide on its surface.

- It releases hydrogen gas when it reacts with strong bases and acids.

- Due to its anodized nature, it is used for decorative finishes.

Physical Properties:

- 6063 aluminum is lightweight with a density of 2.70 g/cm3

- It has a high melting point ranging between 620 and 650 degrees Celsius.

- It conducts electricity and heat very well.

Mechanical Properties:

- The tensile strength of 6063 aluminum is 190 MPa, and the yield strength is 160 MPa, respectively.

- It is moderately ductile and can be elongated by 8% to 10%.

- 6063 aluminum is soft when compared to other alloys of aluminum, with a Brinell Hardness of 73.

- The modulus of elasticity is 69 GPa.

Advantages of Using 6063 Aluminum

Aluminum 6063 offers multiple advantages when implemented in different applications, and some of these are as follows:

Extrudability:

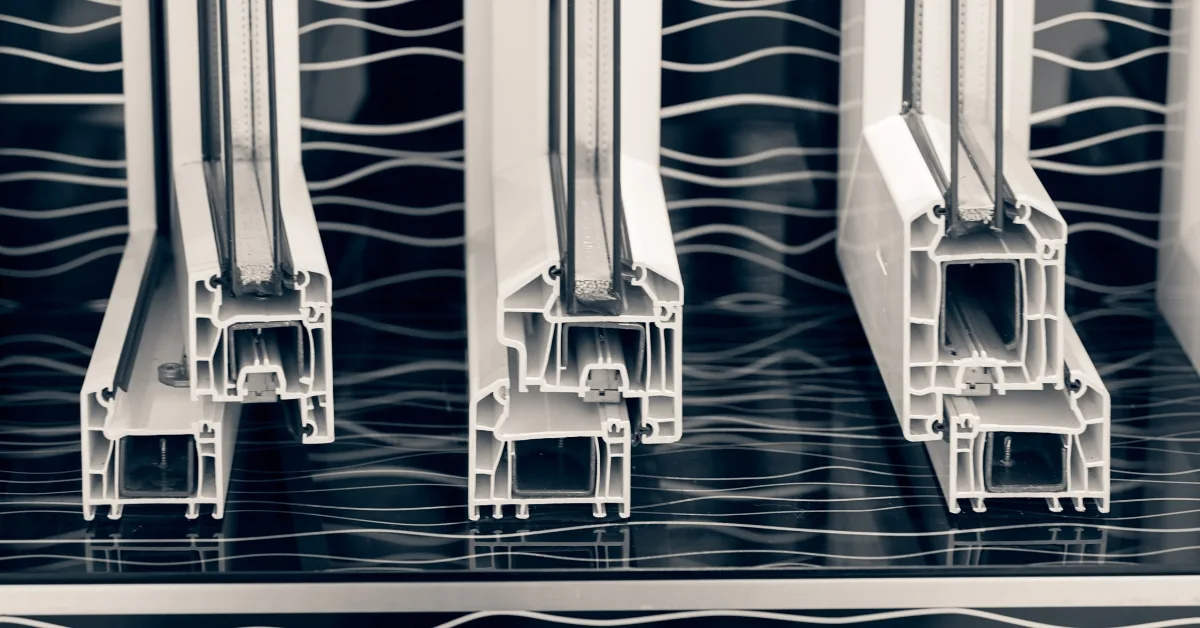

6063 aluminum is highly extrudable and can be converted into multiple shapes, like window frames and heat sinks required for architectural applications. It helps create versatile designs at a very low production cost.

Surface Finish:

6063 aluminum has a lustrous and smooth finish. Due to the surface smoothness, it is widely considered for decorative and architectural applications.

Corrosion Resistance:

When subjected to air exposure, 6063 aluminum creates a layer of oxide that protects it from rusting and corrosion. It is widely used in coastal applications as it can very well resist corrosion.

Workability:

It is highly formable and can be converted into various shapes and styles with the help of an extrusion process. Moreover, it is weldable, and multiple structural and architectural layouts are easily created.

Common Applications Across Industries

6063 aluminum is used in many architectural and structural applications, and some of the common applications are given here:

Piping:

Aluminum 6063 is highly resistant to rust and corrosion. Hence, when used in water lines, irrigation systems, and HVAC systems for piping, it proves to be a great choice.

General extrusions:

The 6063 alloy of aluminum is highly formable that makes it suitable for creating custom profiles and shapes. It is widely adopted in manufacturing enclosures, tracks and frames.

Tubing:

Structural tubing, like handrails, furniture, and frames that require lightweight materials are manufactured using 6063 aluminum. It is also opted for tubing due to its smooth surface finish.

Architectural products:

Architectural products like door frames and window frames require reliable materials. 6063 aluminum is lightweight and durable with a seamless surface finish.

Building & construction extrusions:

Extrusions of 6063 aluminum are used in framing systems and roof panels to ensure the strength and aesthetics of a building.

Marine:

Marine environment requires materials that resist corrosion and 6063 aluminum is suitable for moisture based environments. Therefore, in marine applications it is used for components of boats.

Automotive:

6063 aluminum is used in roof rails, trims and structural components of automobiles. These offer a significant weight reduction with high strength.

Aerospace and Aviation:

In the aviation sector interior components like trims and panels are made using 6063 aluminum due to its corrosion resistance and light weight.

Comparing 6063 to Other Aluminum Alloys

When choosing aluminum 6063 it is important to compare it with other alloys of aluminum to make a sane decision. A detailed comparison between aluminum 6063 and other alloys of aluminum is given below.

6063 vs. 6061 Aluminum:

6063 and 6061 aluminum are both known for their excellent extrusion. They belong to the 6000 series and have silicon and magnesium as their key elements. They are both equipped with high weldability and corrosion resistance, and are even used in many applications.

The major difference between them is that 6061 has a higher strength compared to 6063. Whereas, 6063 is more formable when it comes to complex shapes compared to 6061.

6063 vs. 7075 Aluminum:

Aluminum 6063 has a good machinability, weldability and resistance to corrosion due to which it is suitable for architectural applications. 7075 aluminum has excellent strength and light weight but it is not as resistant to corrosion as 6063 nor is weldable.

6063 Vs. 5052 Aluminum:

5052 aluminum belongs to the 5000 series, which is non-heat treatable. However, 6063 belongs to the 6000 series, which is heat treatable. When compared to 6063, aluminum 5052 is tougher and also offers ease of use due to high workability.

6063 Vs. 6005 Aluminum:

6063 and 6005 aluminum are both used in structural applications. However, 6063 is considered when an aesthetic look followed by high extrusion properties is required. Whereas, 6005 is more suitable for applications that need weldability and strength.

Selection Criteria:

When choosing between aluminum 6063 and other alloys, some of the considerable factors are as follows:

- The strength required for an application.

- Exposure to moisture and corrosion resistance.

- Workability and formability

- Aesthetic requirements

Tempers of 6063 Aluminum

The two tempers of aluminum 6063 T5 and 6063 T6 have different uses and characteristics that are necessary to analyze before implementing them in any application. A comparison to both is given below.

Aluminum 6063 T5 Vs. T6

Aluminum 6063 T5 is the kind of aluminum that is cooled down from a high temperature and is then subjected to aging. It is known for its seamless strength and surface finish which makes it suitable for architectural applications. It is mostly used where aesthetics and formability are crucial.

6063 T6 is a temper of aluminum that undergoes heat treatment after the process of extrusion. This temper is equipped with high strength, but the formability is low, and is used in applications that need high mechanical performance.

Processing and Fabrication Techniques

6063 aluminum passes through three processing and fabrication techniques discussed below.

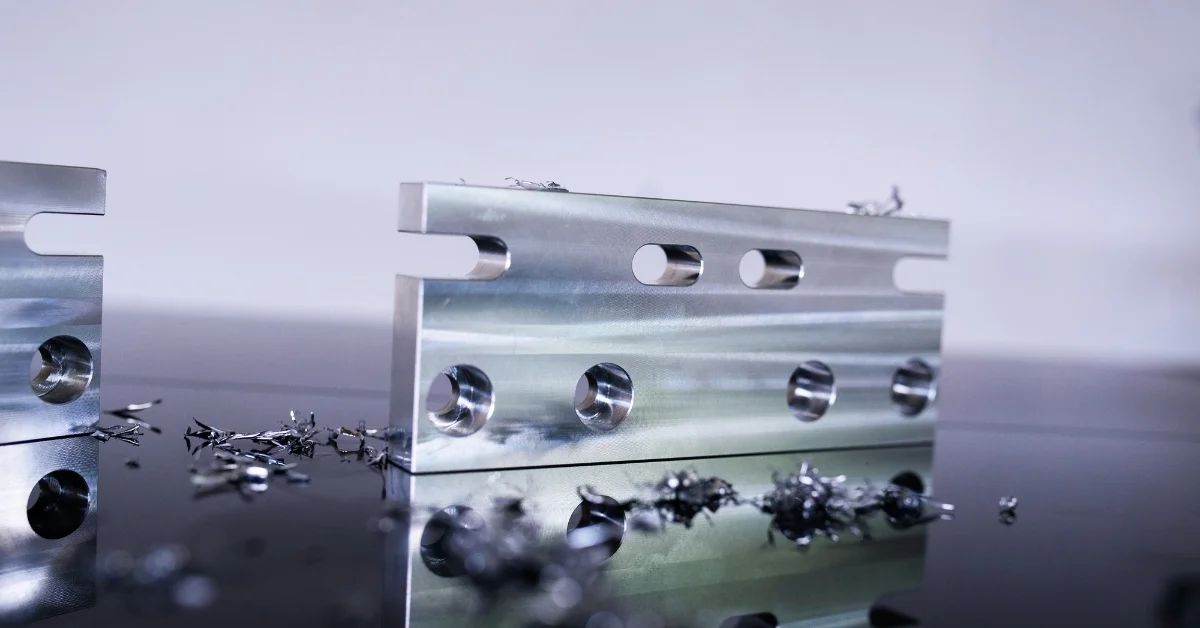

Extrusion Process:

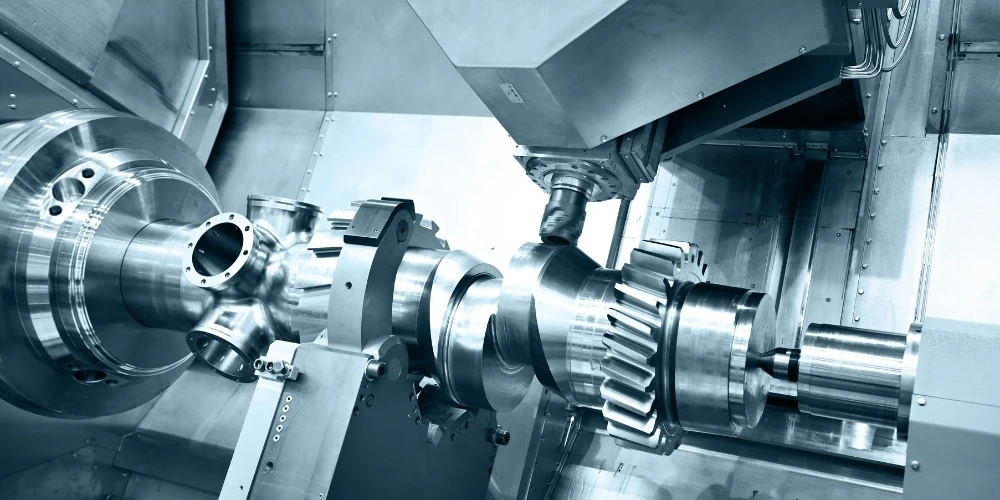

Aluminum 6063 is suitable for the extrusion process because it is highly formable. The process consists of heating billets of aluminum and allowing them to pass through dies to create complex shapes.

The extrusion process is mostly used to create pipes, frames, and other structural parts. The smooth surface of this alloy allows it to keep the tolerance tight, and hence it is suitable for intricate shapes.

Heat Treatment:

To enhance mechanical properties, aluminum 6063 is heated after the extrusion process. Heat treatment strengthens the alloy and adds hardness to it so that it is used for load-bearing applications.

Finishing Options:

6063 aluminum has a high surface finish quality and is also capable of being subjected to various finishing options. When it comes to surface treatments, powder coating, anodizing, and painting are commonly opted for. The different options of finishing add to the aesthetic appeal of the material and also make it corrosion resistant.

Environmental and Economic Considerations

6063 aluminum is not only popular for its corrosion resistance, weldability, and aesthetics, but it also plays a very positive role for the environment. Some of the ways it benefits the environment and economic growth are as follows:

Recyclability:

6063 aluminum is completely recyclable and hence offers environmental friendliness. Due to its recyclability, the reduction in waste and conservation of natural resources is attained.

Cost-Effectiveness:

6063 aluminum is also cost-effective compared to other alloys of aluminum. It is highly extrudable, and hence, the processing time and wastage are reduced. The reduction in waste helps to save on costs, since it is a well-finished material, the cost of added finishing is minimized.

Sustainability:

Aluminum 6063 alloy is a highly durable material. It is equipped with corrosion resistance and needs minimal maintenance. Hence, it is widely used in many applications due to the fact that it is sustainable and doesn’t need replacements.

Conclusion

Understanding about a material before incorporating it in your project is very important for the project success. After reading the guide above you must have understood everything about aluminum 6063.

If you are looking to source custom components for your projects with high accuracy and intricate features made of aluminum 6063, HDC is your go to choice. We offer a wide range of machining services for the custom components of your projects. We use state-of-the-art machines that help us achieve the required precision in each part we manufacture.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!