Custom Stainless Steel Parts Manufacturer

As a foundry with over 10 years, HDC provides stainless steel castings for global customers across industries with unmatched expertise.

With our one-stop custom service from conception to final products and comprehensive casting processes(sand casting, investment casting, die casting), we can cast stainless steel products with complex structures and tight tolerance from a few grams to tens of kilograms.

Industries We Serve

Automotive Industry

HDC implements casting for complex auto parts that require excellent corrosion resistance and good heat resistance, such as supercharger parts and exhaust system.

Process Industries

The pump, valve, and pipeline system is the biggest stainless steel castings application area. HDC is an expert in casting these complex thin-walled parts.

Machinery Industry

Stainless steel castings support the machinery industry with their combined strength, corrosion resistance, and certain wear resistance

Stainless Steel for Casting

HDC provides a wide range of stainless steel for the casting process to satisfy various project requirements.

Austenitic stainless steel is non-magnetic, has excellent corrosion resistance and machinability, and is the type of stainless steel commonly used for casting.

- CF8(≈ 304): The most versatile cast austenitic stainless steel, containing 18% Cr-8% Ni.

- CF3(≈ 304L): A low-carbon version of CF8 (C≤0.03%), commonly used in the food sector

- CF8M(≈ 316): Adding 2%~3% Mo based on CF8, significantly improves the corrosion resistance to chloride, which is often used in chemical and marine fields

- CF3M(≈ 316L): The low-carbon version of the CF8M offers better weldability

Duplex stainless steel has a structure of about 50% austenite + 50% ferrite, which has high strength and excellent stress corrosion resistance.

Martensitic stainless steel is magnetic, generally corrosion resistant, and can obtain high strength and hardness through heat treatment.

CA15(≈ 410): Basic martensitic steel (12%Cr) for components that do not require high wear and corrosion resistance

Ferritic stainless steel has magnetic properties, good oxidation resistance, and sulfur corrosion resistance, but it has relatively poor strength and toughness.

- CB30( ≈ 430): Basic ferritic steel (17%Cr), mostly used in low corrosive environments

- CC50: High chromium ferrite steel (26%-30%Cr), excellent heat and oxidation resistance.

Precipitation hardening stainless steel has been aged to make it have both high strength close to martensitic steel, and good corrosion resistance close to austenitic steel.

CB7Cu-1(≈ 17-4 PH): High strength (yield strength >1000 MPa), excellent corrosion resistance, and dimensional stability, commonly used in aerospace applications and precision castings

Post Treatments We Offer

Our one-stop stainless steel casting service offers comprehensive post treatments to ensure both functionality and appearance.

Heat Treatment

Pickling and Passivation

CNC Machining

Sand/Bead Blasting

Polishing

Stainless Steel Casting Parts

Complex geometries & curved surfaces, thin-walled structures, internal details, all your designs can be turned into realities in HDC.

Why Choose HDC

One-Stop Solutions: Our comprehensive custom service supports you from scratch to the final product.

Multiple Casting Process: We offer sand casting, lost wax casting, and die casting to meet different project requirements.

Rich Custom Options: We offer dozens of materials and surface treatment solutions to help you create the ideal product.

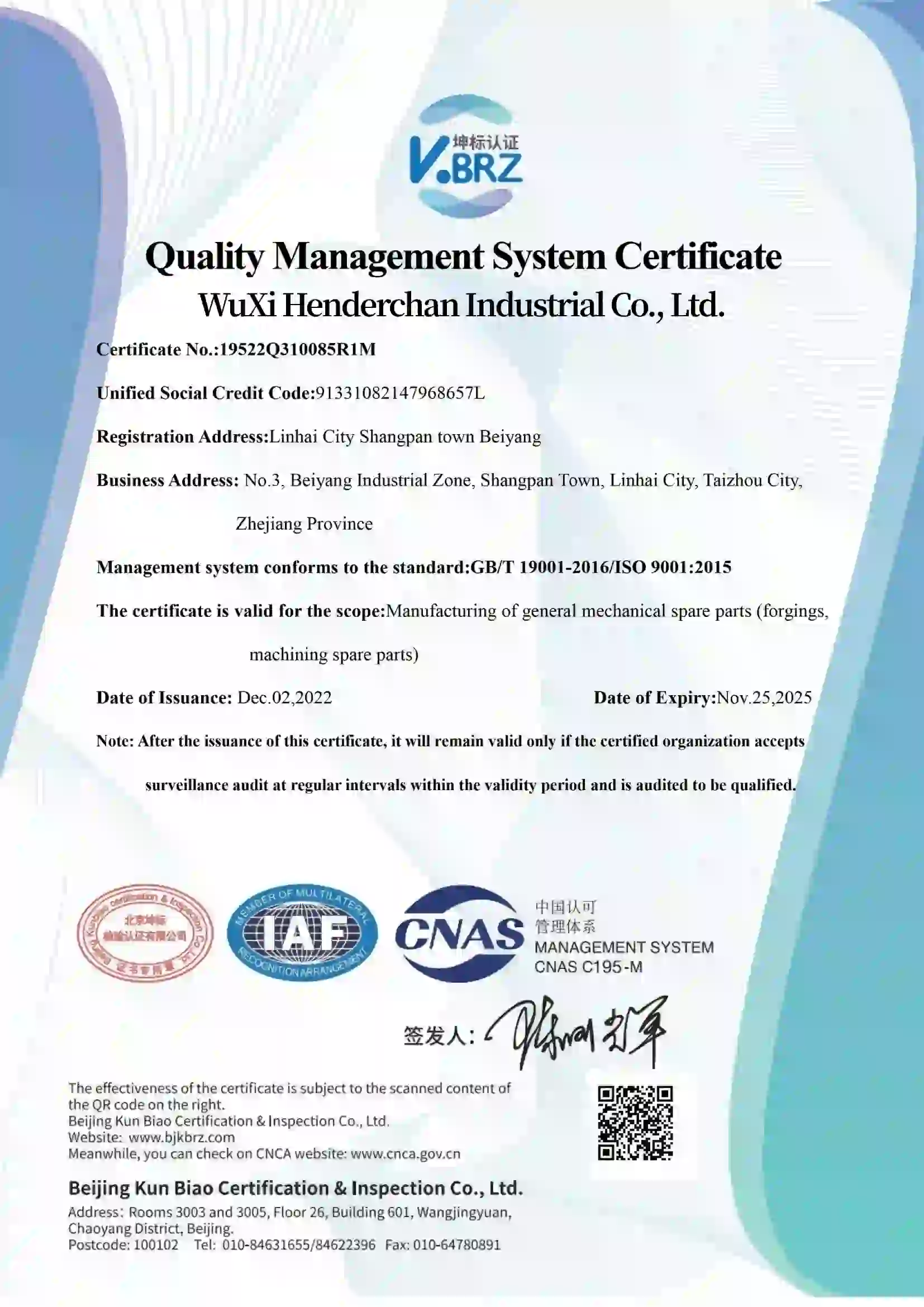

Strict Quality Control: HDC is an ISO certified foundry, we implement strict QA protocol to ensure every product is perfectly functional.

How HDC Cast Stainless Steel

Sand Casting: Capable of producing large-sized, structurally complex stainless steel castings with both cost-effectiveness and rapid delivery capabilities

Investment Casting: Achieve millimeter-level precision and smooth surface seamless stainless steel parts, especially good at thin-walled and complex cavity structures

Die Casting: High-speed mass production of thin-walled stainless steel precision parts, the cost of a single piece is significantly reduced, and it is suitable for large-scale standardized production

Customization Products With a Simple Quote!

Yes, we can help design your product based on samples or sketches, and design optimization is achievable.

Yes, prototype verification is a standard procedure before a production run.

Yes, it depends on the specific project, which is related to the complexity, size, and weight of the product.

Yes, the specific discount is determined by the quantity.

Yes, all customers are welcome to see our factory, please contact us in advance to get an appointment.