Precision Custom Die Casting Parts Manufacturer - HDC

HDC is your ISO-certified partner for high-quality, precision custom die-casting parts. We specialize in transforming your designs into reality with high-performance materials such as aluminum and zinc.

Our engineering expertise and strict quality control ensure consistent performance and reliability of die-cast products in demanding applications such as automotive, electronics, industrial equipment, and more. Get a competitive quote for your project today!

Industries We Serve

Automotive

HDC delivers precision aluminum and zinc die castings like engine brackets, transmission housings, and structural components, meeting IATF 16949 standards.

Consumer Electronics

HDC excels in producing high-precision, thin-wall aluminum die castings for smartphone/tablet frames, laptop chassis, connector housings, and heatsinks.

Industrial Machinery

We manufacture durable aluminum and high-strength zinc die castings for critical industrial applications such as gearbox housings, hydraulic valve bodies.

Die Casting Materials

At HDC, we mainly forge aluminum and steel because of their great formability and excellent mechanical properties.

Surface Finishes

Protect your parts and achieve the desired look with our comprehensive range of secondary finishing services.

Powder Coating

Anodizing (Type II, Type III)

Electroplating

Shot Blasting

Anodizing

Polishing

Why Choose HDC for Die Casting

Expert Design: Our experienced engineers can provide analysis to optimize part design, reduce costs, improve manufacturability, and ensure high yield rates before tooling begins.

Advanced Manufacturing Capability: With the modern 200 to 2000 ton die casting machines and supporting CNC machining, we can handle parts from 0.05 kg to 25 kg with capabilities for thin walls, complex geometries, and tight tolerances down to ±0.05mm.

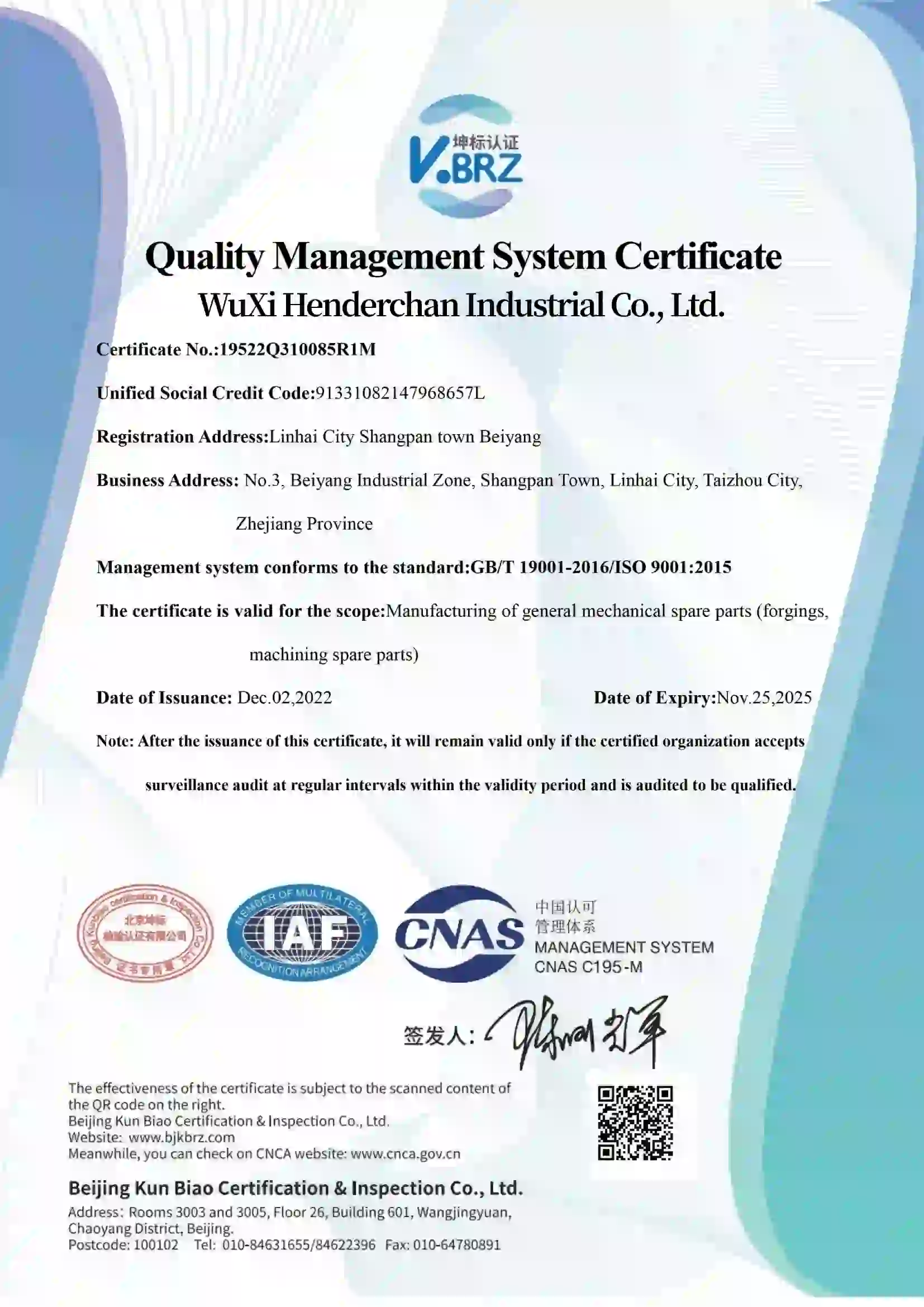

Uncompromising Quality: Certified by ISO 9001:2015 and IATF 16949. We integrated quality control at every stage, from real-time casting monitoring, CMM dimensional inspection, material certification, to defect detection.

Flexibility & Responsiveness: From rapid prototyping to high-volume production, we adapt to your needs with our dedicated project management, ensuring clear communication and on-time delivery

Cost-Effective Solutions: Leveraging efficient mold design, process optimization, and economies of scale to deliver high-quality parts at competitive prices, maximizing your ROI.

Global Support:We offer seamless logistics solutions to ensure reliable delivery worldwide, making your international business as smooth and hassle-free as local sourcing.

HDC Certifications

Customization Products With a Simple Quote!

We require your part drawings and specifications. Our engineers review for manufacturability and provide a detailed quote covering tooling costs and piece-part pricing for your required volumes.

Absolutely! We provide design support as part of our service. Our experts will identify potential issues and suggest optimizations to improve castability, reduce costs, and shorten lead times before tooling starts.

We produce parts ranging from 0.05 kg to 30 kg. For complex geometries requirements, we can achieve 0.1 mm thin wall, and tight tolerances of 0.01mm on critical dimensions. Submit your design for a feasibility assessment.

Absolutely, the specific discount is determined according to the quantity.

Lead times depend on complexity, volume, and finishing requirements, typically range from 4-8 weeks after order confirmation.

Lead times depend on complexity, volume, and finishing requirements, typically range from 4-8 weeks after order confirmation.

Yes, we offer complete in-house tooling services, from design and engineering to manufacturing and maintenance. We build robust, high-precision molds optimized for performance and longevity. Tooling costs are quoted separately

Our MOQ varies depending on part complexity and tooling requirements. We strive to be flexible, accommodating projects from low-volume batches suitable for startups or niche applications to high-volume runs. Contact us to discuss your specific volume needs.