Custom Investment Cast Impellers & Blades for Demanding Applications

HDC manufactures high-performance impellers and blades using precision investment casting, ideal for fluid handling, turbines, compressors, and more.

• Complex Geometries &Tight Tolerances

• Stainless Steel & Super Alloy Casting Expertise

• OEM & Custom Design Support

Our Key Advantages

Intricate blade angles and flow-optimized designs are achievable with our investment casting techniques.

Stainless steel, nickel-based alloys, and high-temperature materials for various industrial needs.

We offer finish machining, polishing, dynamic balancing, heat treatment, and other post-processing services.

Flexible Production

Suitable for OEMs, replacement parts, and specialized industrial components.

Customization Options

| Material | Stainless steel, nickel alloys, or custom alloys |

| Blade Design | Open, semi-open, closed, or custom shapes |

| Dimensions | Diameter, thickness, blade height, bore size, blade count, and shaft fit |

| Surface Finish | Polished, coated, or as-cast |

| Tolerance | Machining and casting tolerances can meet ±0.05mm or better. |

| Heat Treatment | Solution heat treatment, aging, or stress-relief. |

By Structure / Design Type

We manufacture impellers in a full range of structures to suit different fluids, operating conditions, and efficiency goals.

Open Impeller

Blades are exposed on both sides, making it easy to clean and great for liquids with small amounts of debris.

Semi‑Open Impeller

One side has a cover for extra support, the other is open. Good balance between handling solids and maintaining efficiency.

Closed Impeller

Blades are enclosed between two plates. Delivers higher efficiency and better pressure for clean liquids.

Channel Impeller

One or more flow channels guide the fluid through. Handles solids and fibers without clogging.

Screw Impeller

Spiral-shaped blades move fluid smoothly, perfect for thick or delicate materials.

Vortex Impeller

Recessed in the casing, creating a swirling flow. Reduces wear and helps avoid blockage.

By Application

We make impellers and blades for a wide range of uses, from everyday pumps to high-performance turbines.

Turbine Blades

High-temperature and fatigue-resistant, built for energy and power generation turbine wheels.

Compressor Blades

Optimized for aerodynamic efficiency in compressors and HVAC systems.

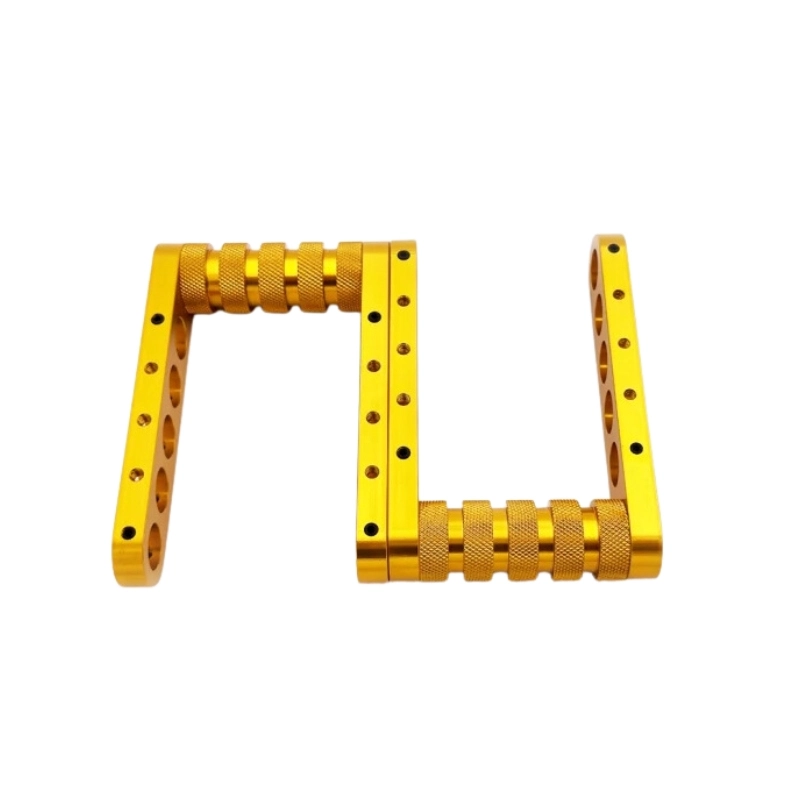

Mixer & Agitator Blades

Designed for food, chemical, and pharma processing with fluid compatibility in mind.

Fan Blades

Lightweight and durable for industrial blowers and ventilation systems.

Centrifugal Pump Impellers

The most common type in industrial pumps, smooth, efficient for liquid transfer.

By Flow Direction

Whether your system requires which flow direction, we have the engineering expertise to deliver the right solution.

Radial Flow Impeller

Moves fluid perpendicular to the shaft. Best for high-pressure, low-flow jobs.

Axial Flow Impeller

Moves fluid parallel to the shaft. Ideal for high-flow, low-head systems like mixers or fans.

Mixed Flow (Diagonal) Impeller

Combines radial and axial features. Balances flow rate and pressure, common in wastewater and chemical pumps.

By Material

We cast in a wide selection of high-performance alloys to meet demanding operational and compliance requirements.

Stainless Steel

Corrosion-resistant and easy to clean. It’s a solid all-round choice.

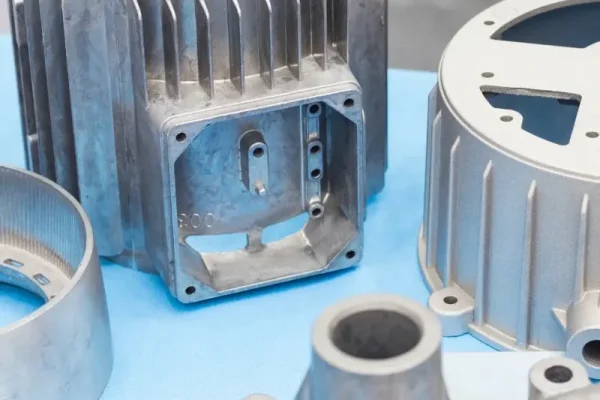

Aluminum Alloys

Lightweight and rust-free, making it great for fans and low-temperature systems.

Bronze & Brass

Excellent wear and seawater resistance. Commonly seen in marine impellers.

Nickel-Based Superalloys

Withstands extreme heat and stress, perfect for turbines and high-temp compressors.

Investment Casting Advantages on Impeller Manufacturing

One-shot casting process, perfect for complex blade geometries — built for performance and precision.

- Complex Shapes in One Piece

Accurately reproduce blade angles and flow passages without welding or extra assembly. - Wide Range of Industrial Materials

Stainless steel, bronze, aluminum alloys, nickel-based superalloys — for all operating conditions. - High Precision & Consistency

Tight tolerances for better hydraulic performance and easier dynamic balancing. - Cost-Effective for Low to Medium Volumes

Ideal for OEM batches, replacements, and special-purpose impellers.

How HDC Support Your Custom Project

From new designs to replacement parts — we handle everything from drawings to finished impellers.

- Design Review: Check your drawings, suggest manufacturing optimizations, and avoid costly rework.

- Sampling & Tooling: Produce samples for shape and fit confirmation before making high-precision molds.

- Casting & Cleaning: Investment casting, shell removal, de-burring, and heat treatment in one streamlined process.

- Machining & Balancing: CNC finishing, grinding, and dynamic balancing for low-vibration performance.

- Surface Treatment & Inspection

Polishing, passivation, coating, plus NDT and inspection reports as needed. - Delivery & Ongoing Support: Custom packaging, on-time shipping, and continued technical assistance.

Ready to bring your design to life?

Send us your drawings or concept, and we’ll turn them into precision-cast impellers or blades ready for your application.

FAQ

We work with stainless steel, carbon steel, aluminum alloys, and nickel-based superalloys like Inconel, covering most industrial needs.

We specialize in OEM and custom designs. Send us your drawings or samples, and we can manufacture to your exact specifications.

For most new designs, a minimum order is required due to mold tooling costs — especially for complex impellers. The specific MOQ needs to be negotiated based on the project.

However, we can produce smaller batches if you’re willing to cover tooling and higher per-unit pricing.

Yes. Investment casting allows us to achieve tight tolerances, and we can also provide CNC machining for critical dimensions.

Standard lead time is 4–6 weeks depending on complexity and order size. Rush orders can be arranged when possible.

We offer polishing, passivation, coating, and other surface treatments to improve performance and durability.

Yes. We regularly export to most countries on earth, including North America, Europe, and Asia, with secure packaging and reliable logistics.