Custom Casting Exhaust Manifold & Header Parts Manufacturer

Specialized in investment casting and precision machining, HDC provides custom exhaust manifold service for your brand with our years of metal fabrication expertise.

Exhaust Manifold Parts We Fabricate

With comprehensive manufacturing capabilities, HDC brings any of your exhaust manifold designs to life.

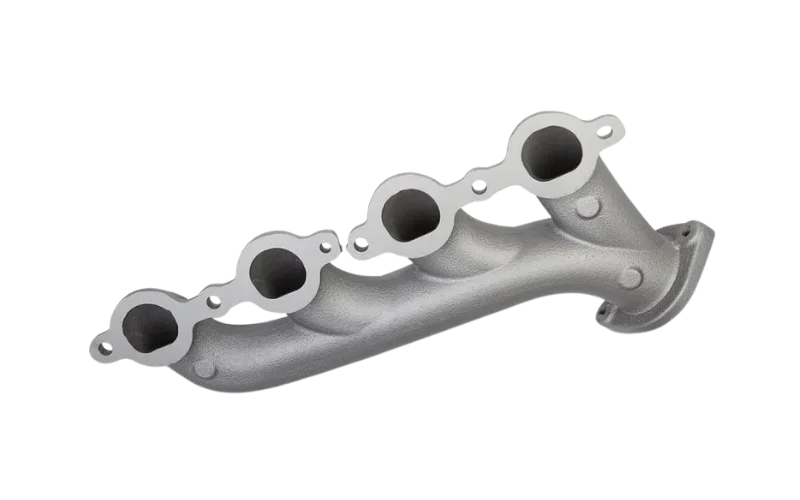

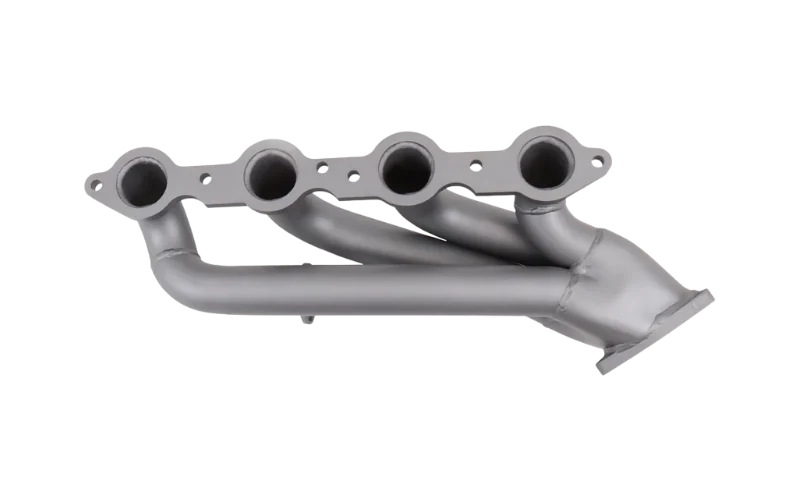

Automotive Exhaust Manifold

Whether your exhaust manifold is for an inline or V-type engine, NA or turbocharged, racing modification or OEM spare, HDC can make it for you.

Motorcycle Exhaust Manifold

HDC offers exhaust manifold for both scooters and racing motorcycles, using investment casting for precision manufacturing.

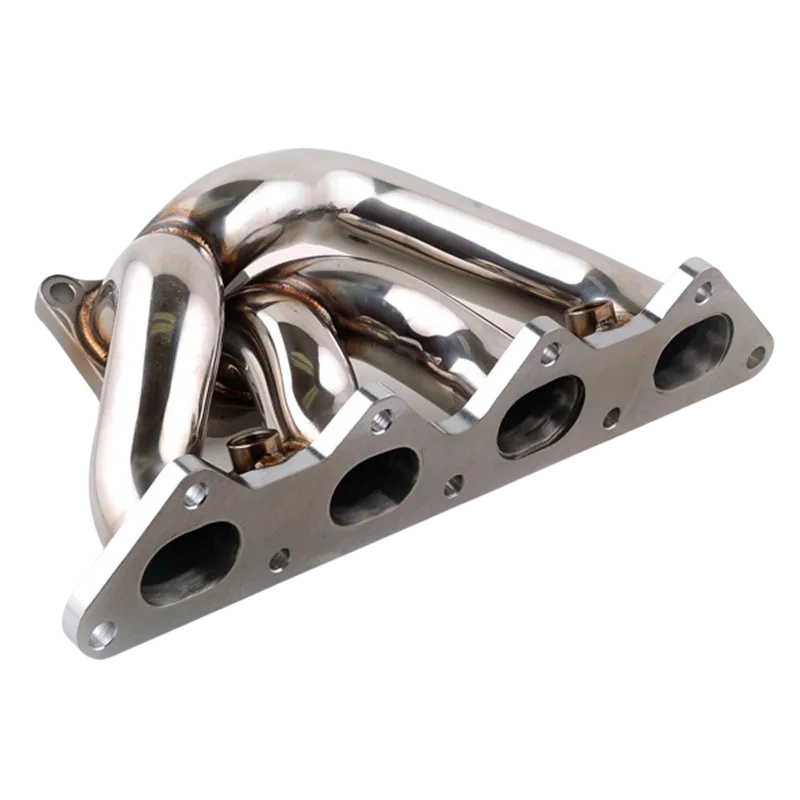

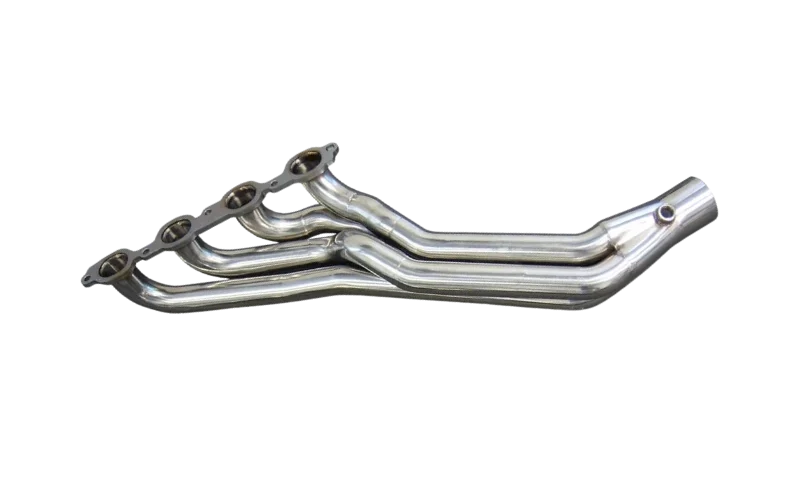

Long Tube Exhaust Header

A long exhaust tube is a common selection in racing cars, in which area we have served many customers in Europe for years.

Short Tube Exhaust Header

A short tube exhaust manifold is usually applied for a regular car. HDC is capable of mass production of OEM exhaust emission parts for it.

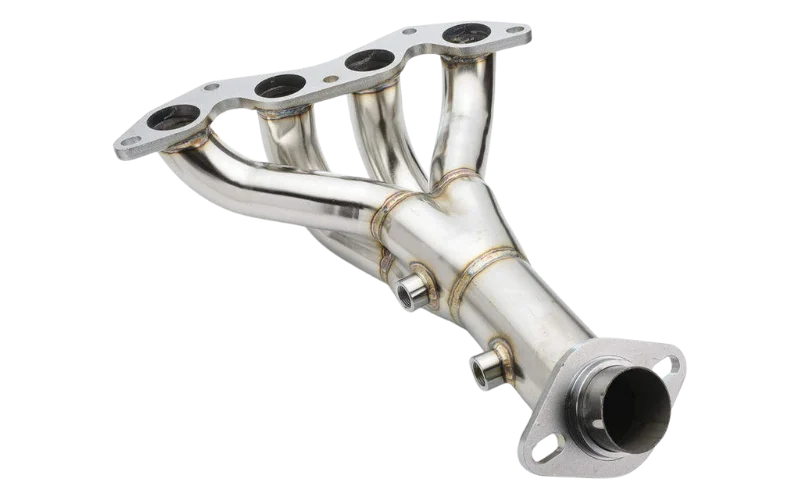

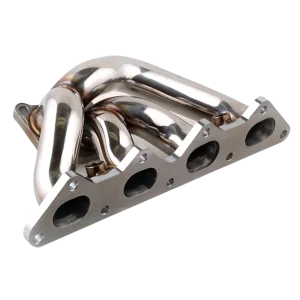

4-1 Exhaust Manifold

With rich experience in casting, We can help to custom build your 4-1 exhaust manifold that can improve engine performance at a high rpm.

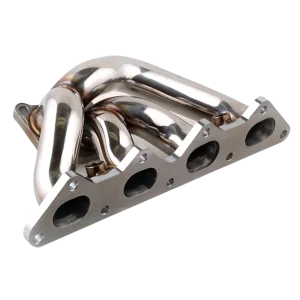

4-2-1 Exhaust Manifold

4-2-1 exhaust manifold has a balanced performance in both low rpm and high rpm, HDC build it with stainless steel or steel.

Exhaust Manifold Collector

This is a essienal parts that helps to collect gas from every cylinder together, we can cast it in 4 in 1 or 3 in 1 type as per your request.

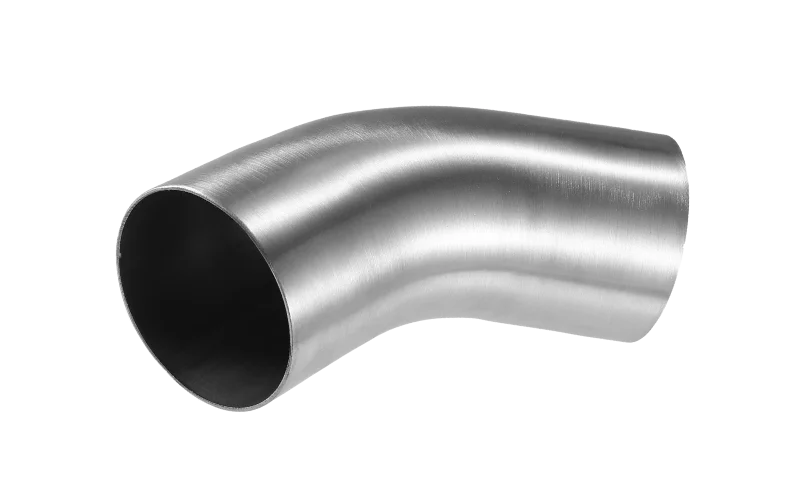

Exhaust Manifold Tube

It’s a common way to cast these tubes and weld them together to build an exhaust pipe. We cast them in any degree to fit your design.

Exhaust Manifold Mounting Flange

A mounting flange is a flat plate machined with exhaust ports and tapped holes. Typically, we manufacture it by CNC machining.

Why Choose HDC

What HDC can do for your business? Here is the answer.

Precision Investment Casting

HDC utilizes investment casting to cast high performance one-piece exhaust manifold, which can achieve complex hollow structure and lightweight thin-wall design.

Wide Range of Material Options

We cast exhaust parts with a wide range of metals, including cast iron, carbon steel, stainless steel, nickel alloy, etc. All your material requirements can be fulfilled here.

One Stop Customization Solution

With the capabilities of casting, CNC machining, and welding, we build your customized exhaust manifold parts from raw material to final product with seamless in-house metalworking.

Worldwide Service

HDC provides multilingual support to ensure smooth and barrier-free communication. We also export to most countries worldwide, offering flexible shipping terms such as DDP, DDU, and FOB.

How HDC Fabricate Exhaust Parts

HDC fabricates exhaust parts from raw metal to the final product with comprehensive in-house capabilities

Investment Casting

Lost wax casting is an ideal method to cast products with complex geometry and thin-walled structures. Therefore, it shows superior ability in manufacturing exhaust manifolds. That’s why HDC utilizes it to fabricate one-piece exhaust manifold or exhaust parts.

CNC Machining

After casting and cleaning, the exhaust manifold needs to be CNC finished for key dimensions, including mounting surface, mounting holes, and threads. HDC is equipped with 3-axis and 4-axis CNC machining centers, which allow us to ensure high precision and consistent quality.

Welding & Assembly

HDC not only provides casting exhaust manifold parts, but also offers fully assembled exhaust systems. Available welding methods include TIG, MIG, and laser welding, with the specific method determined by material requirements and product specifications.

Material Available for Exhaust Parts

Comprehensive material options for different vehicle requirements

Cast iron is the mainstream material for manufacturing exhaust manifolds in the internal combustion engine(ICE) vehicle industry. It is cost-effective and provides good thermal resistance, noise damping, and mechanical strength.

At HDC, we use it to cast the one-piece exhaust manifold, usually an OEM replacement in car repair.

The carbon steel exhaust manifold has better strength and toughness. Still, the heat resistance is not as good as cast iron, so it is mainly used for a small displacement engine, for example, motorcycle, small construction machinery, and generator.

At HDC, you can get both low-carbon steel(AISI 1010 / 1020 / 1030) and medium-carbon steel(AISI 1045 / 1050) for your custom exhaust system.

The stainless steel exhaust manifold is favored by high-end vehicles and modified turbocharged cars due to its overall superior heat and corrosion resistance compared to cast iron and carbon steel.

Stainless steel is our major material in producing the exhaust manifold as it well well-suited for investment casting. The common grades we use include CF8 and CF8M.

Titanium exhaust manifolds often showed up in aftermarket modifications for luxury cars or high-performance racing cars. It’s favored by the excellent strength-to-weight ratio, heat, and corrosion resistance. But the high material and manufacturing fee keeps most enthusiasts out.

At HDC, we utilize vacuum investment casting to produce these essential parts, along with our mature supply chain, making titanium a good choice for a custom exhaust manifold.

If you need an exhaust manifold that can maintain functionality after a long time running in an extreme heat environment(over 1000°C), then nickel alloy is your only choice, since it offers the best strength, antioxidant, and thermal fatigue resistance at high temperatures.

HDC cast nickel alloy grades such as Inconel 718 and Inconel 625 for the custom exhaust system.

Material Comparison for Exhaust Manifolds

| Comparison Item | Titanium Alloy | Nickel Alloy | Stainless Steel | Cast Iron / Carbon Steel |

|---|---|---|---|---|

| Maximum Operating Temperature | 750–850 °C | 1100–1150 °C | 900–1050 °C | 700–850 °C |

| Oxidation Resistance | Moderate (requires protective coating) | Excellent | Good | Fair |

| Thermal Fatigue Resistance | Good | Excellent | Good | Low |

| Strength-to-Weight Ratio | Very High | Medium | Low to Medium | Low |

| Weight | Lightest | Relatively Heavy | Medium | Medium |

| Corrosion Resistance | Excellent in wet or humid environments | Excellent | Good | Fair |

| Manufacturing Cost | Very High | High | Moderate | Low |

| Weldability / Machinability | Difficult (requires vacuum welding or special tools) | Difficult | Good | Excellent |

| Typical Applications | Racing cars, motorcycles, aerospace components | Extreme high-temperature engines | Turbocharged gasoline engines | Standard mass-production vehicles |

Custom Surface Treatment Options

We are not just manufacturing it. We finish the surface as well

Bead blasting creates a uniform matte finish by propelling fine abrasive media onto the surface.

HDC uses bead blasting to remove casting marks, CNC machining lines, and welding residues, providing a smooth, clean base for painting, coating, or polishing. It is suitable for cast iron, carbon steel, stainless steel, titanium, and nickel alloy manifolds.

Coating offers additional heat and corrosion resistance for high-performance manifolds. It can withstand extreme temperatures and extend the life of the exhaust system.

HDC provides ceramic, anti-oxidation, or thermal barrier coatings suitable for stainless steel, nickel alloy, and titanium manifolds.

We polish stainless steel, nickel alloy, and titanium manifolds to produce a smooth, reflective surface that improves appearance and reduces surface roughness.

Passivation removes free iron from the surface and forms a protective oxide layer.

It is usually applied on stainless steel and nickel alloy manifolds to enhance corrosion resistance and maintain long-term durability, especially in high-temperature and humid environments.

Heat coloring creates a visually appealing, gradient finish on stainless steel, titanium, and nickel alloy manifolds.

By controlling heat treatment, we are able to produce gold, blue, purple, and rainbow effects, giving manifolds a high-end look without affecting mechanical properties.

Technical Specifications

Check out our capabilities in manufacturing your customized exhaust manifold

| Wall Thickness | 2.5 – 6.0 mm (controlled depending on design & alloy) |

| Casting Tolerance | ±0.2 mm (investment casting) |

| Machining Tolerance | ±0.05 mm (CNC finishing) |

| Surface Roughness (Ra) | 1.6 – 3.2 μm (after CNC), < 6.3 μm (as-cast) |

| Welding Method | TIG / MIG / Laser Welding (with post-weld heat treatment available) |

| Weld Seam Quality | 100% visual and leak-tested; optional X-ray or dye penetrant inspection |

| Dimensional Accuracy | ±0.5 mm overall assembly tolerance |

| Max Operating Temperature | Up to 1050 °C (depending on material) |

| Pressure Resistance | Up to 6 bar (boosted turbo applications) |

| Heat Treatment | Solution annealing / stress relieving available after welding or casting |

| Production Capacity | Up to 10,000 units per year (custom tooling available) |

| Customization | Fully customizable per OEM / performance application drawings |

Need to build a Custom Exhaust System?

Reach out to HDC, then you get the most expert one-stop forging product solution you can find. Just send an email, our quote is free!

FAQ

What do exhaust manifolds do?

An exhaust manifold collects exhaust gases from the engine cylinders and sends them to the exhaust pipe. It helps reduce back pressure and improves engine performance.

Where is the exhaust manifold located?

It is connected to the cylinder head of the engine. Each cylinder has a port that joins the manifold.

How do I know if my exhaust manifold needs replacing?

You may hear a ticking or leaking noise from the engine area, smell exhaust gases, or see reduced engine power. These are signs the manifold or gasket may be damaged.

Can I drive with a bad exhaust manifold?

It is not recommended. A leaking manifold can reduce performance, cause more fuel consumption, and even damage the engine or catalytic converter.

How long do exhaust manifolds last?

Normally they can last 5 to 10 years or more, depending on the material, engine temperature, and driving condition.

What need to consider before ordering custom exhaust manifold?

You need to confirm the engine model, material, surface finish, and connection type. Also, please prepare the 3D or 2D drawings for quotation.

Can HDC suggest the best casting or machining process for my exhaust parts?

Yes. Based on your material and design, HDC engineers will suggest the most suitable process, such as investment casting, CNC machining, or welding.

Which material is the best for an exhaust manifold?

It depends on your application and budget. Cast iron and carbon steel are good for standard engines. Stainless steel and nickel alloy are better for high-temperature or performance engines.