Custom Forged Lifting & Rigging Components for Industrial Applications

Backed by years of experience in forging and machining, HDC provides custom service for your custom lifting & rigging hardware project.

- Precision close-die forging

- Custom forged to your design or sample

- One-stop solution from forging to CNC finishing

What Can HDC Offer

From forged blanks to fully machined, assembly-ready components — choose the delivery level that fits your production stage.

Forged Blanks

Pros: Mass production of forged near-net shape rigging equipment blanks based on your design, ensuring cost-effective and exceptional strength.

Best Fit For: OEM manufacturers or brands that can handle post-machining and surface treatment.

Machined Forged Blanks

Pros: Precision forged rigging gear blanks with critical dimensions finished by CNC machining, offering balanced cost and quality requirements.

Best Fit For: Customers who can handle surface treatment or only require as-machined finishes for their projects.

Assembly-Ready Components

Pros: Ready for direct assembly lifting components, ensuring dimensional consistency, stable batch quality, and streamlined supply chain management.

Best Fit For: Customers who have sufficient budget and are seeking one-stop manufacturing solutions.

Typical Lifting & Rigging Components We Customize

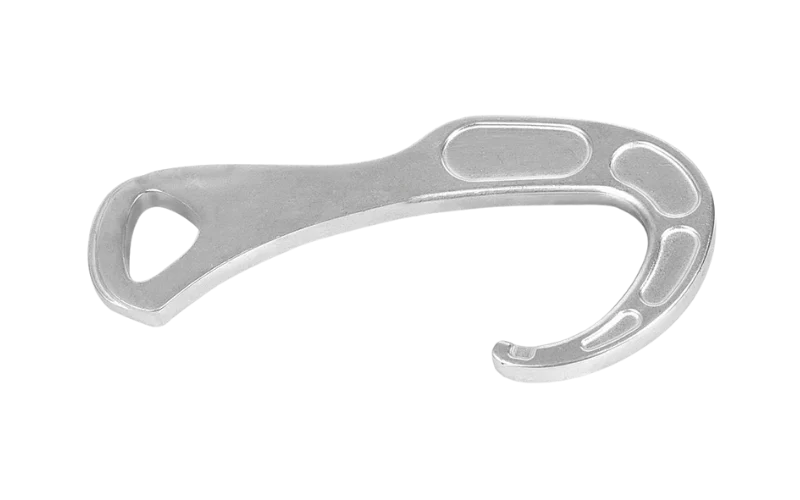

Forged Hooks

Custom forged hooks with high-strength steel, suitable for heavy duty industrial applications. Customizable in size, throat opening, and material.

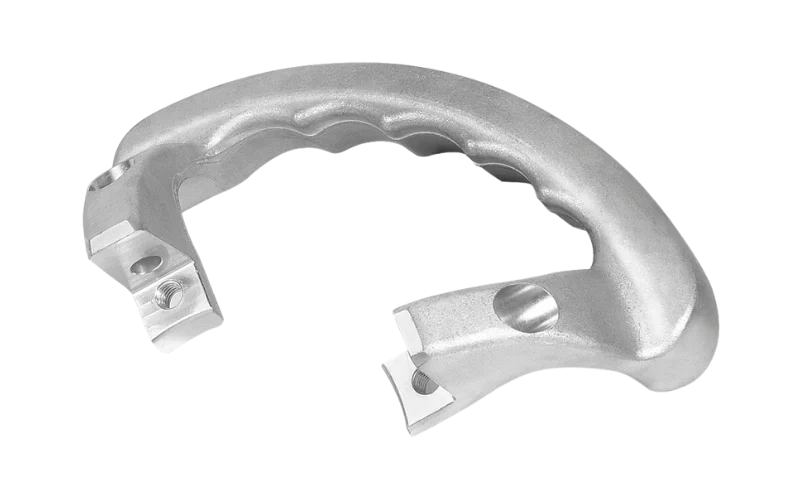

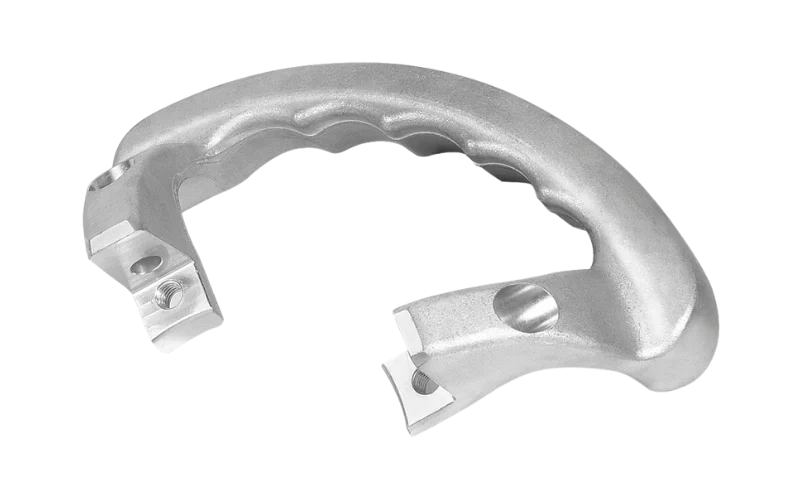

Forged Shackles

Bow and D-shackles forged for extreme durability. Custom pin types and wide-body designs available for specific rigging setups.

Forged Eye Bolts

Precision forged and machined. We offer custom thread sizes and stem lengths, adhering to strict shoulder pattern standards for angular lifting.

Forged Eye Nuts

We supply anchorage points forged from Carbon or Alloy steel for superior tensile strength. Custom threads and oversized dimensions available.

Forged Turnbuckles

We can manufacture Jaw-Jaw, Eye-Eye, or Hook-Eye configurations. Forged bodies and machined ends for smooth adjustability and heavy tensioning.

Forged Swivels

Designed to prevent wire rope twisting. We combine precision forging with CNC machining to ensure smooth rotation under load.

Forged Cable Clamp

We forge the clamp base with close-die forging, offering significantly higher holding power and resistance to deformation compared to malleable iron clips.

Forged Connecting Links

Through forging, we fabricate the critical link in your chain. Hammerlocks, Master Links, and Coupling Links forged for varying chain sizes and working load limits.

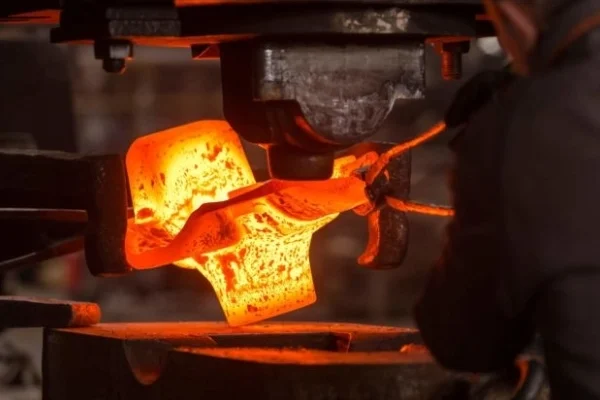

Why Forge for Lifting & Rigging Hardware

Superior Strength

Forging refines the grain flow of lifting component, resulting in better strength and fatigue resistance under high load.

Optimized Internal Defects

Through heat and high pressure, forging can eliminates cavaties and pockets inside metal, which is crucial for safe lifting applications.

Controlled Mechanical Properties

The physical properties of forged lifting parts can be controlled by proper heat-treatment to achieve the desired hardness and tensile strength.

Cost-Effective Mass Production

Close-die forging offers higher production speed and lower material waste, making it a cost-effective process for medium to high-volume production.

HDC Core Capabilities

Why choose HDC for your custom rigging parts project? Here is the answer.

Close-Die Forging

We forge lifting hardware with precision machined die, which can achieve a high production rate and reduce material waste.

Heat Treatment

Various heat treatments can be applied to meet your performance requirements for rigging gear, such as quenching, tempering, and aging.

CNC Finishing

With comprehensive CNC machining capabilities, we offer you on-stop solution for custom lifting and rigging component projects.

For a full overview, please visit our Forging and CNC Machining Capability pages.

Materials for Custom Forged Lifting Hardware

Surface Finishes for Lifting & Rigging Hardware

Backed by a solid supply chain in surface finishing, HDC offers you a wide range of surface finishes to meet your custom options requirements.

| 🔷 Zinc Plated | 🔷 Black Oxide |

| 🔷 Powder Coated | 🔷 Polished |

| 🔷 Brushed | 🔷 Anodized |

Typical Applications of Forged Lifting & Rigging Hardware

Different industries demand different standards. Whether you need high-load hooks or lifting parts designed for a unique feature, we provide OEM manufacturing tailored to the unique challenges of your sector.

| 🔷 Industrial Lifting Equipment | 🔷 Construction & Infrastructure Projects |

| 🔷 Mining, Oil & Heavy Industry | 🔷 Marine & Offshore Handling |

| 🔷 OEM Equipment Manufacturing: |

Ready to Forge Your Custom Rigging Hardware?

Click the button below and specify your requirements. We’ll get back to you with a quote within 12 hours.

FAQs

Do you supply standard lifting and rigging hardware?

No, HDC is focusing on providing custom metal forging solutions to customers. Standard products are not supplied.

Can you manufacture lifting and rigging hardware based on drawings or samples?

Yes. We manufacture forged lifting and rigging components strictly according to customer-provided drawings, samples, and technical requirements.

What types of forging processes do you use?

We primary utlize close-die forging for lifting and rigging hardware. For specific projects, we can also provide a compatible forging process with our reliable supply chain.

What materials are commonly used for forged lifting and rigging hardware?

We mainly work with three types of materials: stainless steel, carbon steel, and aluminum alloy. Specific material can be supplied based on your requirements.

Are your forged lifting components suitable for safety-critical applications?

Our forging processes focus on strength and structural integrity. Final application suitability and compliance requirements are defined by the customer’s design and application standards.