Casting defects are one of the biggest reasons a “good-looking” part turns into delayed shipments, unexpected machining time, or rejected inspection reports. The tricky part is that many defects don’t show up clearly at first glance. A casting can look acceptable on the surface but still fail later due to porosity, shrinkage voids, warpage, inclusions, or cracks—especially once you begin CNC machining or pressure testing.

This article explains casting defects in a practical, production-focused way. You’ll learn what the most common defects are, what typically causes them, how they show up during machining and inspection, and what a supplier should control to prevent them.

What Are Casting Defects?

Casting defects are unintended imperfections in a cast component that reduce quality, performance, or dimensional reliability. Some defects are cosmetic, but many are structural—meaning they directly affect strength, leak-tightness, fatigue life, and machinability. Defects can originate from molten metal behavior, mold/shell quality, gating and feeding design, melting practice, contamination, or process control issues during solidification and cooling.

The reason this matters is simple: most downstream pain—extra rework, inconsistent tolerances, tool wear, scrap—comes from defects that were “baked in” before the part even reached machining.

Why Casting Defects Matter for Machining and Tolerances

If your finished part relies on tight datums, sealing faces, precision bores, or threaded features, casting quality becomes the foundation of your machining plan. Porosity near a sealing face can cause leaks after machining. Hard inclusions can destroy tools and ruin surface finish. Distortion or warpage can shift stock allowance and force additional setups. Even mild shrinkage variation can cause recurring out-of-tolerance results that look like a machining issue but actually started in the casting.

A useful way to think about this is: the cleaner and more stable the casting, the less machining you need to “fight the part” to reach the drawing.

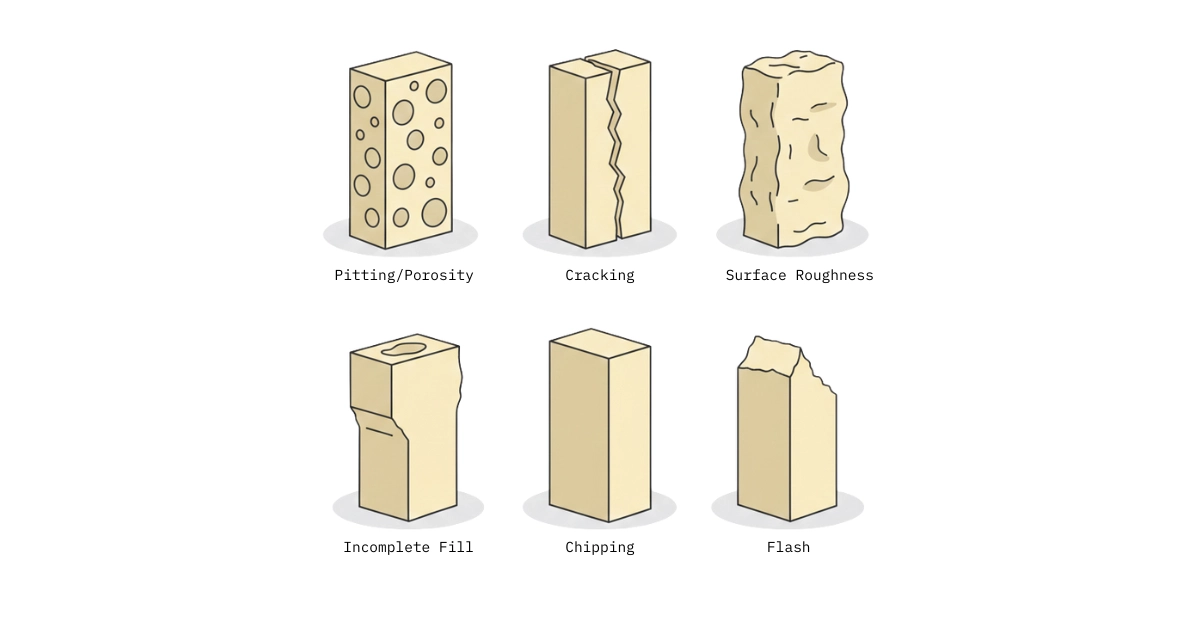

Common Casting Defects and What They Usually Mean

Most casting defects fall into a few repeating patterns. Once you learn the “symptom → likely cause” logic, you can diagnose issues faster and ask better questions during sourcing.

Porosity (Gas Porosity and Micro-Porosity)

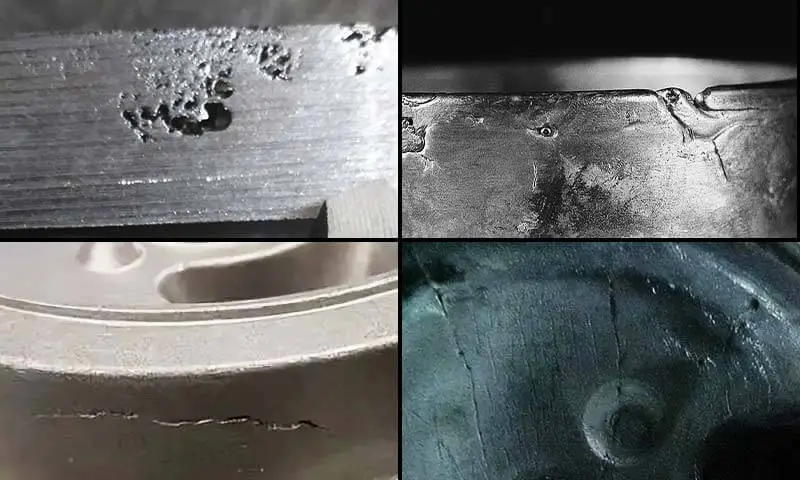

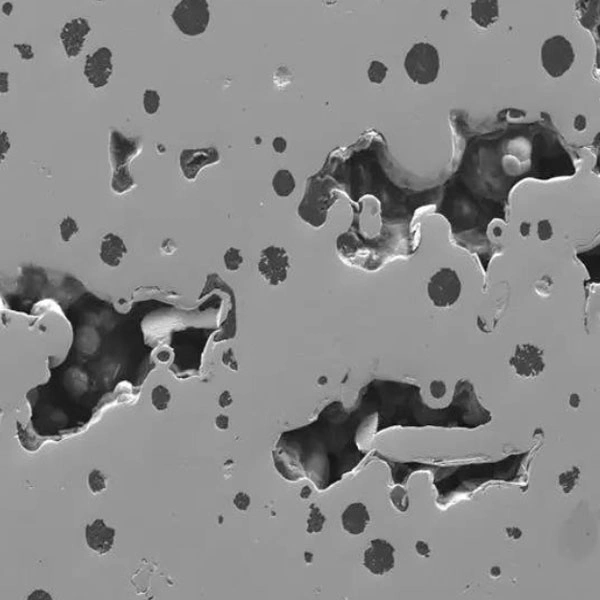

Porosity shows up as small holes or sponge-like areas in the metal. Sometimes you’ll see it on the surface, but often it appears only after machining exposes internal pockets. Gas porosity is commonly linked to trapped gas, moisture, or turbulence during pouring. Micro-porosity is often tied to solidification behavior and inadequate feeding in thicker sections. In practical terms, porosity becomes a big deal when you need pressure-tight parts, smooth sealing faces, or consistent mechanical properties.

Shrinkage Defects (Shrinkage Cavities and Shrinkage Voids)

Shrinkage happens when the metal contracts as it solidifies and there isn’t enough feed metal to compensate. This can create cavities or internal voids, typically in heavier sections or hot spots. Shrinkage defects can be especially painful because you may not detect them until machining opens them up, at which point the part is already carrying added value and time.

Cold Shut and Misrun

A cold shut occurs when two streams of metal meet but don’t fuse properly. A misrun happens when metal fails to completely fill the mold. Both often point to temperature, flow, gating design, or section thickness issues. These defects tend to show up as seam-like lines, incomplete edges, or weak areas that can crack under load.

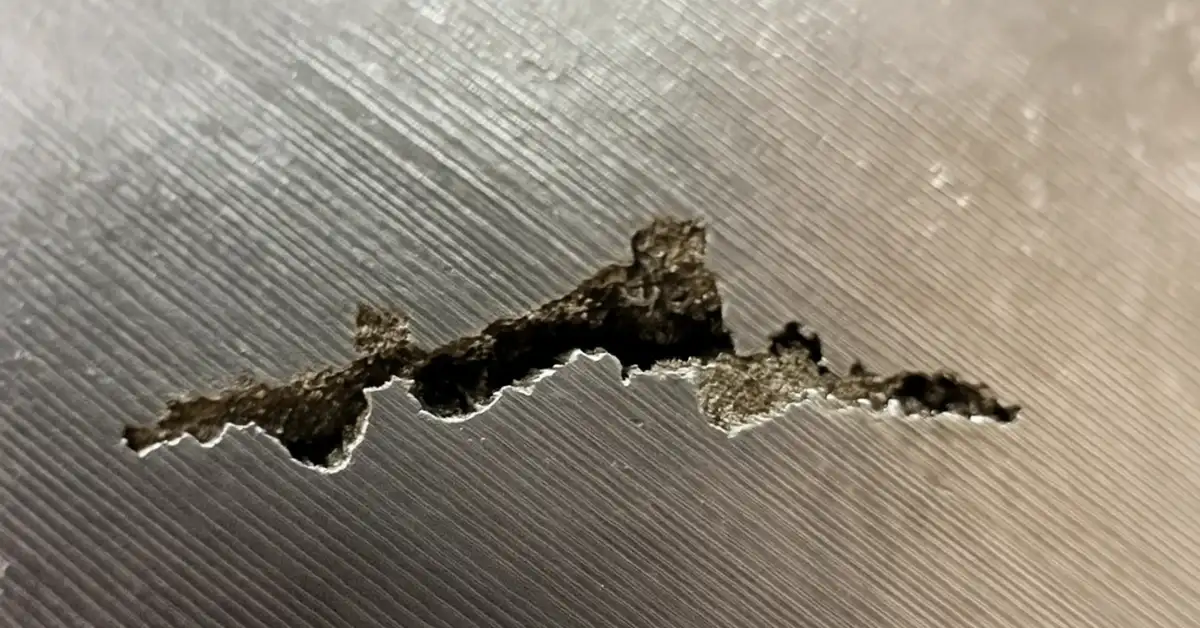

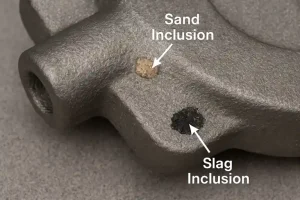

Inclusions (Slag, Oxides, Sand/Ceramic)

Inclusions are unwanted non-metallic particles trapped inside the casting. They often show up during machining as hard spots, tearing, tool chipping, or unexpected surface pitting. Inclusions usually trace back to melt cleanliness, filtration, turbulence, or mold/shell break-off. If tool life is mysteriously poor or surface finish won’t clean up, inclusions are worth suspecting.

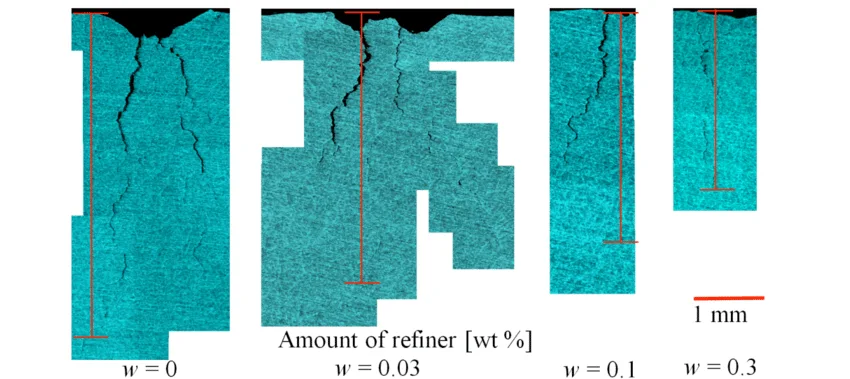

Hot Tears and Cracks

Cracks can form while the casting is cooling and contracting, especially where geometry creates restraint or sharp transitions. Hot tears are a classic solidification-stage cracking problem, often influenced by alloy behavior, design stress points, and cooling control. These defects can be obvious or hairline, and they can become catastrophic if the part faces cyclic stress or pressure.

Warpage and Distortion

Some distortion is normal, but excessive warpage often indicates uneven cooling, poor support during solidification, or geometry that naturally moves as it shrinks. Warpage becomes expensive when it forces extra straightening, extra machining stock, or multiple re-clamping steps to recover datums.

Surface Defects (Roughness, Scabs, Laps, Penetration)

Surface problems can come from mold erosion, shell issues, metal/mold reactions, or turbulence. Even when they’re “cosmetic,” surface defects often increase grinding and polishing time and can reduce confidence in near-net outcomes.

A Simple Defect-to-Impact Map (What You’ll Feel Downstream)

Here’s a quick way to link defects to what you actually experience later:

| Casting defect | How it shows up later | Why it hurts |

| Porosity | leaks, failed pressure test, pitting after machining | sealing faces and threads become unreliable |

| Shrinkage voids | cavities revealed during CNC, scrap after value-add | unpredictable internal defects |

| Inclusions | tool wear, chatter marks, torn finish | hard particles damage tools and finish |

| Cold shut/misrun | weak seams, broken edges | structural risk and rejection |

| Cracks/hot tears | failed NDT, failure under load | safety and fatigue risk |

| Warpage | datums shift, extra setups | tolerance recovery becomes costly |

This is why strong suppliers treat defect prevention as a design + process control problem, not a final inspection problem.

What Typically Causes Casting Defects

Casting defects usually come from one of four buckets: metal quality, mold/shell quality, gating/feeding design, and process control. Metal quality includes things like contamination, moisture, dissolved gas, and inconsistent chemistry. Mold or shell quality includes issues like permeability, strength, moisture, and debris. Gating and feeding design is where turbulence, air entrapment, and hot spots are either solved or created. Process control includes pouring temperature, pour rate, cooling pattern, and consistency of cycle-to-cycle handling.

Most recurring defects are not “random.” They’re usually repeatable outcomes of an uncontrolled variable.

How to Reduce Casting Defects Before They Reach Machining

The most effective approach is to prevent defects where they form, rather than trying to machine around them. That usually means controlling the melt, reducing turbulence, improving feeding, and stabilizing cooling behavior. It also means being realistic about geometry: sharp corners, abrupt section changes, and heavy-to-thin transitions are defect magnets unless the design and gating are engineered carefully.

From a practical sourcing perspective, it helps to align early on which surfaces are intended to be as-cast and which will be machined. When critical features will be machined, you still want a casting that’s stable and defect-free in those areas so machining can be predictable and repeatable.

What to Ask a Supplier When Casting Defects Are a Risk

If your part is pressure-retaining, safety-critical, or tolerance-sensitive, you want clarity on how defects are prevented and how quality is verified. Ask how porosity is controlled, how feeding is designed for thick sections, and how cleanliness is maintained to avoid inclusions. If NDT is required, confirm which method applies and which areas are inspected. Also ask how the supplier manages dimensional stability and warpage control, because distortion can quietly cause chronic tolerance issues that look like machining variation.

The goal is not paperwork—it’s confidence that the process is engineered to avoid defects in the first place.

FAQ: Casting Defects

What are the most common casting defects?

The most common casting defects typically include porosity, shrinkage voids, inclusions, cold shuts/misruns, cracks or hot tears, warpage, and surface defects. Which ones dominate depends on alloy, geometry, and process control.

What causes porosity in castings?

Porosity is often caused by trapped gas, moisture, turbulence during pouring, or solidification behavior that creates micro-porosity in thicker sections. Porosity frequently becomes visible only after machining opens internal areas.

What is shrinkage in casting and why does it happen?

Shrinkage happens because metal contracts as it solidifies. If the casting isn’t fed properly as it cools—especially in heavy sections—voids and cavities can form inside the part.

How do inclusions affect machining?

Inclusions can cause rapid tool wear, chipped inserts, tearing on the surface, and inconsistent finishes. They may show up as hard spots or pitting that doesn’t clean up even with extra machining passes.

Can casting defects be fixed after the part is made?

Some defects can be repaired in limited situations, but many defects (especially internal porosity, shrinkage voids, and cracks) are best treated as prevention issues. Repairs may also introduce risk for critical or pressure-bearing parts.

How do casting defects affect tolerances?

Defects can shift datums through warpage, create variable stock allowance, expose voids when finishing to size, or compromise sealing faces. This increases rework, scrap risk, and inconsistency in meeting tight tolerances.

What inspections detect casting defects?

Visual inspection helps with obvious surface issues, but internal defects often require non-destructive testing methods depending on requirements. For pressure-tight parts, additional verification is commonly needed beyond appearance alone.

What’s the best way to reduce casting defects in a new part?

Start by aligning geometry and process early: avoid sharp transitions, engineer gating/feeding for hot spots, control melt cleanliness, and validate the process with first-article inspection and stability checks before scaling volume.

Conclusion

Casting defects aren’t just a foundry problem—they directly affect machining time, tolerance reliability, inspection results, and total delivered cost. When the casting is clean and stable, machining becomes straightforward: fewer surprises, fewer tool issues, fewer scrap events, and more predictable output.

If your part is tolerance-sensitive or performance-critical, the fastest path to consistent results is to address defect prevention early by aligning geometry, process controls, and inspection expectations before production ramps up.

At HDC, we address casting defects at the source to provide reliable casting service. We review part geometry early, control melt cleanliness and solidification behavior, and design gating and feeding to minimize porosity, shrinkage, and distortion—so castings remain stable, machine cleanly, and meet tolerance expectations in production.