Aluminum Weld On Hinges

HDC, Aluminum Weld On Hinges Manufacturer In China. As the premier manufacturer of OEM Metal Parts, has been producing the welding hinges for more than 6 years, aluminum weld-on bullet hinges are one of our competitive welding hinges. With advanced machines, skilled technicians, and experienced workers, we always offer your competitive cost and high-level quality.

- ISO9001 Certificated manufacturer

- Lightweight, and durable

- Large stock for common sizes weld-on hinges

- Industrial leading machines and tools

- Free Samples available for quality approval

What Is Aluminum Weld On Hinges

Aluminum Weld-On Hinges consist of stainless steel pin and bushing that provide a support point for installation. You can choose whether have grease fittings or not. Grease fittings are great for easy lubrication. Aluminum weld-on hinges can be a good choice if you need your bullet hinges to be light and durable. They can resist corrosion well while in harsh environments outside. Moreover, Aluminum weld-on hinges can be connected securely and they look clean, smooth, and fashionable. They can be applied in many areas, such as shipping containers, military vehicles, security gates, and several other things.

All Different Aluminum Weld On Hinges HDC Produce

Our aluminum weld-on hinges are made of 6063 Aluminum, assembled with 304 stainless steel pin and washer, the length is from 60mm to 200mm, To meet your different needs, it can be capable from 52kg to 650 kg, with all the machining finished on CNC Machines.

Our aluminum weld-on hinges are manufactured by 6063 Aluminum, fitted with 304 stainless steel pin and washer, we can get grease zerk fitted as needed. To suit your different requirements, Its capacity is from 52kg to 650kg, and all the hinges are produced in CNC Machines.

Besides standard sizes of aluminum welding hinges, we also can customize hinges from your designs, such as aluminum weld-on bar hinges, and weld-on butterfly hinges, Just send us your designs, and we can produce them from your drawings.

Not Only Aluminum Welding Hinges

We also provide Stainless Steel and steel weld one hinges for your project.

1. Stainless Steel: Composed of stainless steel body and bushing. The weight capacity is from 52kg to 650kg. You can choose whether have grease zerk or not. They have excellent strength, durability, and corrosion resistance. They can be applied in marine, medical, food service, and many other industries. Their appearance is clean and smooth and the connection is secure.

2. Steel Bullet: Steel body with steel or brass pin and washer. The length comes from 40mm to 200mm, and the weight capacity can be adjusted from 52kg to 1200kg. You can choose whether have grease hinges or not. Even if they sound ordinary, they are extremely strong and sturdy. They are a superior cost considerable choice when you need superior corrosion resistance.

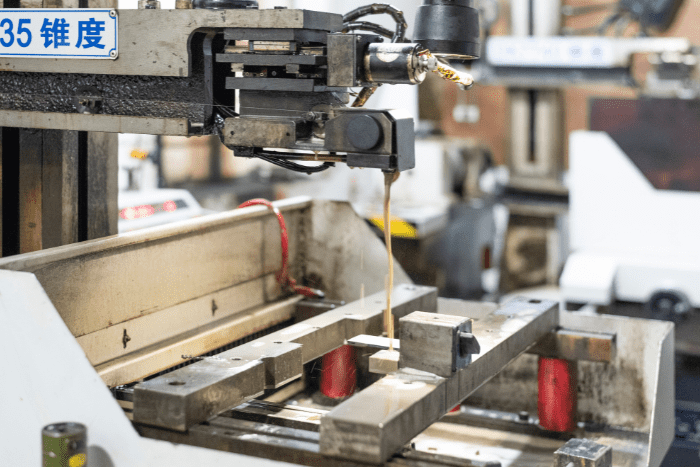

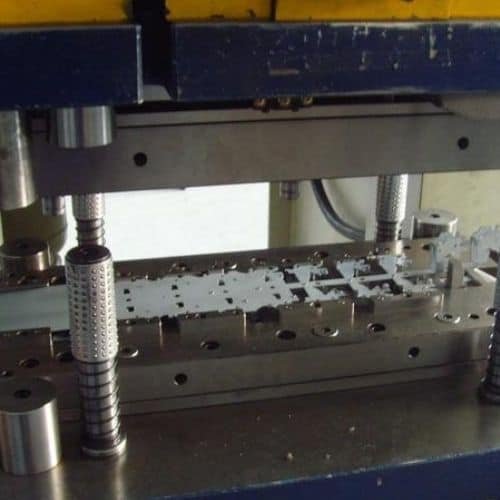

HDC Capabilities On Weld on Hinges

Aluminum weld-on hinges| The Complete FAQ Guide

What are the main applications of aluminum weld-on hinges?

Aluminum weld-on hinges are ideal for installation in areas where there is little space available and the strength of the weld is high. Furthermore, often aluminum hinges are used in places where lightweight hinges are required. Aluminum is one of the best materials that provide high strength without increasing the weight of the hinge. Here are a few of the most common applications of aluminum weld-on hinges:

Shipping Containers

Aluminum weld on hinges serves as the ideal hinge to contain heavy loads of shipping containers. Furthermore, Aluminum does not corrode easily in the humid and moist environment at sea, making it an ideal choice for shipment containers. Also, the space in shipping containers is very small so the weld-on hinges serve as the best hinges on containers.

Military Vehicles

Military vehicles require dependable weld-on hinges that can survive in various terrains and weather. Therefore, Aluminum weld-on hinges are ideal for military vehicles that have to face extreme weather conditions.

Security Gates and Doors

Aluminum weld-on hinges are extremely durable and provide great strength to gates and doors. So, these hinges are ideal for installation at doors and gates that are heavy-duty and sturdy. A few common examples are the hinges on vaults, safety doors, etc.

Fire Doors

Fire doors require to be resistant to extreme conditions of a fire. Also, the fire doors have very compact space and require to operate effectively in a small area. Aluminum weld-on hinges provide the best strength-to-weight ratio for fire doors, therefore, these hinges are ideal for such applications.

What type of Aluminum weld-on hinges does HDC offer?

HDC offers aluminum weld-on hinges in various types, sizes, and dimensions. We manufacture aluminum hinges with the body of aluminum and pins of 304 stainless steel. HDC provides aluminum hinges in all lengths and sizes. You can provide us with the specifications of size and dimensions you need and we can make a custom weld-on hinge for you. Also, we provide zerk fitting (if required) so that you can grease the hinge without removing it.

What are the benefits of buying Aluminum weld-on hinges from HDC?

On-time delivery

We make sure that all our aluminum weld-on hinges are produced within the timeframe that we promise to our clients. So, you will not have to worry about overtime orders or late deliveries. The in-time deliveries will make the order worth your money.

Professional Team

Our team is highly skilled in manufacturing all types of aluminum hinges and will deliver products that will be durable and high in quality. Plus, the design will be developed on the latest CAD software so that you will have the opportunity to order the same part again.

High-quality material

The aluminum we use for the weld-on hinges is of the highest quality available in the market. You will not have to worry about corrosion or removing the hinges any time soon. All our weld-on hinges are durable and long-lasting.

No reworking required

Reworking is one of the biggest nuisances when dealing with non-professional manufacturers. However, HDC will ensure that you will not have to get any reworking after the final product is with you. Also, we have a highly skilled team at HDC that uses the latest machinery for manufacturing aluminum weld-on hinges. As a result, you will not have to worry about reworking of the delivered orders.

Competitive price

Despite the fast turnaround time and the high quality of our aluminum weld-on hinges, you will get a very competitive rate. For more details on the number of orders and the applicable rates, you can contact us.

How to install Aluminum weld-on hinges?

As the name suggests, the weld-on hinges are welded onto the metallic host surface instead of being bolted like other types of hinges.

With regards to welding, here are the basic steps to installing an aluminum weld-on hinge:

Step 1: Mark the position on the surface where you want to install the hinges.

Step 2: Position the male part of the hinge towards the frame where the gate will fix. Use two tacks on either side of the hinge to position it perfectly in the frame. In case, there is any misalignment, you can use packing to provide proper alignment.

Step 3: Slide the female part of the hinge onto the pin and weld the hinges on both sides.

Step 4: Once the installation is complete, you need to check whether the aluminum weld-on hinge has been properly seated or not. In case, the gate is not properly seated or there is any vibration, you need to fix the issue.

You can also refer to a professional company for the installation of aluminum hinges.

What are the main parts of Aluminum hinges?

There are three main parts of the Aluminum weld-on hinges as follows:

- Male part: This is the barrel side with a pin.

- Female part: This is the leaf side and it is the barrel side without a pin.

- Bush: It sits between the two halves of the barrel.

The female barrels are welded on the moving part of the surface, like the gates, doors, etc. Whereas, the male barrel is welded onto the non-moving part of the structure i.e. door frames, etc. Usually, the doors that use weld-on hinges are lift-off doors. Therefore, you need to position the barrel without the pin, i.e. the female part towards the top. This will increase the load-bearing capability of the weld-on hinge.

Since the weld-on hinges need to be structurally strong to protect against breaking, it is advisable to weld the hinge properly.

In addition to the above, you will need a welding torch to weld the aluminum weld-on hinge to the surface. Also, you need to be careful that the weld will only be possible on a metal surface or metal alloy. Do not try to weld the hinge onto a wooden structure.