Overview

Overview

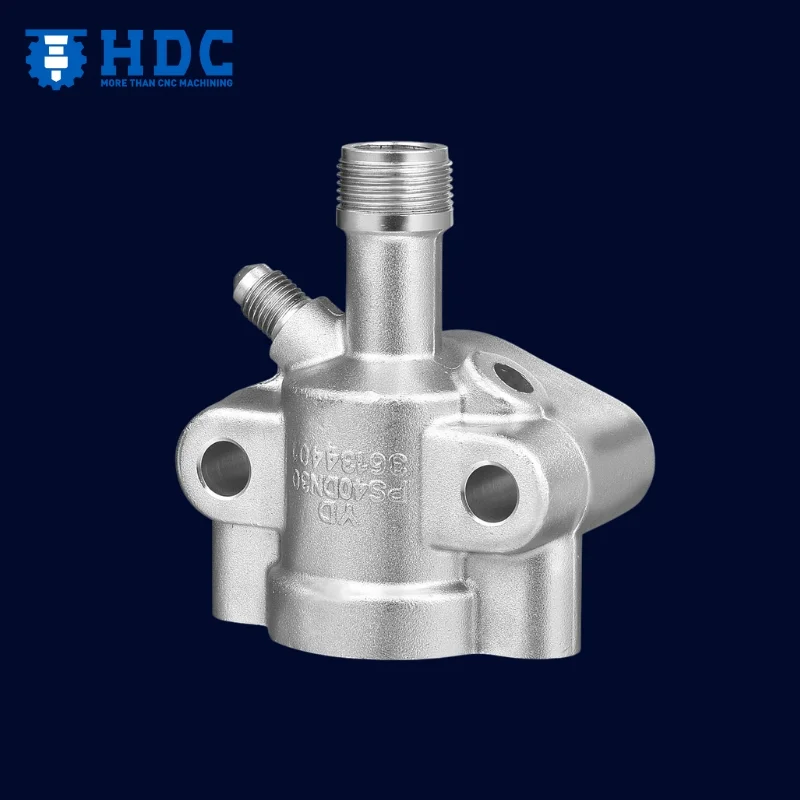

HDC Manufacturing has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your 316 stainless steel components to perfection, tailored to your specific requirements.

Compared with 304 stainless steel, 316 stainless steel is used in harsher environments with greater corrosion resistance, tensile strength, and acidic resistance, such as in medical equipment, aerospace engineering, food processing equipment, and marine application, it is the second most popular stainless steel materials, next to 304, at the same time, 316L has better corrosion resistance due to its low carbon.

Chemical Composition

| Component | Wt.% |

| Carbon (C) | 0.08 % |

| Chromium (Cr) | 16.0 – 18.5 % |

| Iron (Fe) | 62.0 – 72.0 % |

| Manganese (Mn) | 2.0 % |

| Molybdenum (Mo) | 2.0 – 3.0 % |

| Nickel (Ni) | 10.0 – 14.0 % |

| Nitrogen (N) | 0.10 % |

| Phosphorus (P) | 0.05 % |

| Silicon (Si) | 1.0 % |

| Sulfur (S) | 0.03 % |

Mechanical Properties

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 550 MPa | 79800 psi |

| Tensile Yield Strength | 240 MPa | 79800 psi |

| Elongation at Break | 60 % | 60 % |

| Hardness, Rockwell B | 80 | 80 |

| Hardness, Brinell | 149 | 149 |

| Hardness, Knoop | 169 | 169 |

| Hardness, Vickers | 155 | 155 |

| Modulus of Elasticity | 193-200 GPa | 28000-29000 ksi |

| Izod Impact | 129 J | 95.1 ft-lb |

| Charpy Impact | 105 J | 77.4 ft-lb |

Physical Properties

| Material Density | 8.0 g/cm³ |

| Mean Thermal Expansion Coefficient | 16.5 μm/m/°C |

| Mean Thermal Conductivity | 18.9 W/m*K |

| Specific Heat Capacity | 500 J/kg*K |

| Electrical Resistivity | 740 (nΩ*m) |

| Melting Onset | 1380 °C / 2510 °F |

| Melting Completion | 1400 °C / 2550 °F |

| Embodied Energy | 53 MJ/kg |

| Calomel Potential | -50 mV |

Equivalent Materials

| EU | EN | X5CrNiMo17-12-2 (1.4401) | ||

| USA | – | 316 | ||

| Germany | DIN,WNr | X5CrNiMo17-12-2 | ||

| Japan | JIS | SUS316 | ||

| France | AFNOR | Z6CND17-11 Z7CND17-11-02 Z7CND17-12-02 | ||

| England | BS | 316S31 | ||

| Italy | UNI | X5CrNiMo17-12 | ||

| China | GB | 0Cr17Ni12Mo2 | ||

| Sweden | SS | 2347 | ||

| Czechia | CSN | 17346 | ||

| Austria | ONORM | X5CrNiMo17-12-2KW | ||

| Russia | GOST | 08KH16N11M3 | ||