What Is Inconel?

Inconel is a family of nickel-chromium superalloys known for their exceptional strength, corrosion resistance, and ability to perform well under high temperatures. Developed by the International Nickel Company (INCO), Inconel is made primarily from nickel, chromium, and iron, with other elements like molybdenum, niobium, and cobalt added to enhance its properties. Thanks to its resistance to oxidation and creep, Inconel is widely used in industries like aerospace, chemical processing, marine engineering, and power plants. Different grades of Inconel are tailored to meet the needs of high-performance environments.

Origin of the Name Inconel Alloy

The name “Inconel” comes from a blend of “Inco,” referencing the International Nickel Company (INCO), the original producer, and “-nel,” likely short for “nickel,” a key element in the alloy. Trademarked by Special Metals Corporation, Inconel alloys are known for their resistance to oxidation and corrosion, especially in high-temperature environments. This makes them ideal for extreme conditions like jet engines, chemical processing, and nuclear reactors.

How Many Types of Inconel Alloy Are There?

Inconel alloys come in several types, each made to handle different tough environments. Take Inconel 600, for example. It’s a go-to for heat processing jobs, while Inconel 625 is all about strength and durability, often seen in aerospace and marine settings. If you need something that can take the heat, Inconel 718 fits the bill—it’s great in the aerospace world too. For corrosion resistance, Inconel X-750 stands out.

There are also specialized variants like Inconel 725 and 740H, which cater to the oil, gas, and power plant industries. The Inconel family is always evolving, offering solutions for the ever-changing needs of industrial applications.

Disadvantages of Inconel

While Inconel excels in high-temperature and corrosive environments, it does come with some drawbacks. It’s expensive, hard to machine, and requires complex welding techniques. The material is also heavier and has a higher thermal expansion rate compared to others, which can be a downside in certain applications. Additionally, Inconel’s availability can be limited, and working with it often demands specialized tooling and highly skilled labor, further driving up costs. Despite these challenges, Inconel remains a top choice for critical industries like aerospace, chemical processing, and power generation, where its unique properties outweigh the disadvantages.

Chemical Composition of Inconel

| Component | Wt. % |

| Ni | 50 – 55 |

| P | Max 0.015 |

| S | Max 0.015 |

| Si | Max 0.35 |

| Ti | 0.65 – 1.15 |

| Al | 0.2 – 0.8 |

| B | Max 0.006 |

| C | Max 0.08 |

| Co | Max 1 |

| Cr | 17 – 21 |

| Cu | Max 0.3 |

| Fe | 17 |

| Mn | Max 0.35 |

| Mo | 2.8 – 3.3 |

| Nb | 4.75 – 5.5 |

The Role of Various Elements in Inconel

Inconel’s impressive heat and corrosion resistance comes from its unique blend of elements. Nickel forms the base, giving it strength and stability, while chromium prevents rust. Molybdenum adds even more corrosion resistance, especially against chemicals. Aluminum and titanium contribute to high-temperature strength through a process called precipitation hardening. Elements like niobium and iron boost strength and further protect against corrosive environments.

Small amounts of cobalt, carbon, manganese, and silicon enhance the alloy’s overall performance, improving its stability, weldability, and formability. This combination of elements allows Inconel to excel in extreme conditions, making it essential for industries like aerospace, chemical processing, and power generation.

Physical Properties of Inconel

| Physical Properties | Metric | English |

| Density | 8.19 g/cc | 0.296 lb/in³ |

Mechanical Properties of Inconel

| Mechanical Properties | Metric | English |

| Tensile Strength, Ultimate | 1375 MPa | 199000 psi |

| Tensile Strength, Ultimate at Elevated Temperature | 1100 MPa | 160000 psi |

| Tensile Strength, Yield | 1100 MPa | 160000 psi |

| Tensile Strength, Yield at Elevated Temperature | 980 MPa | 142000 psi |

| Elongation at Break | 25% | 25% |

| Elongation at Break at Elevated Temperature | 18% | 18% |

Electrical Properties of Inconel

| Electrical Properties | Metric | English |

| Electrical Resistivity | 0.000125 ohm-cm | 0.000125 ohm-cm |

| Magnetic Permeability | 1.0011 | 1.0011 |

| Curie Temperature | -112 °C | -170 °F |

Thermal Properties of Inconel

| Thermal Properties | Metric | English |

| CTE, linear 20°C | 13 µm/m-°C | 7.22 µin/in-°F |

| Specific Heat Capacity | 0.435 J/g-°C | 0.104 BTU/lb-°F |

| Thermal Conductivity | 11.4 W/m-K | 79.1 BTU-in/hr-ft²-°F |

| Melting Point | 1260 – 1336 °C | 2300 – 2440 °F |

| Solidus | 1260 °C | 2300 °F |

| Liquidus | 1336 °C | 2440 °F |

Can Inconel Used in Casting?

Absolutely, Inconel can be used in casting, and it’s actually a go-to material for industries that deal with high temperatures and corrosion, like aerospace and power generation. Inconel’s super strength and resistance to oxidation make it ideal for tough environments.There are a few common ways to cast Inconel:

Absolutely, Inconel can be used in casting, and it’s actually a go-to material for industries that deal with high temperatures and corrosion, like aerospace and power generation. Inconel’s super strength and resistance to oxidation make it ideal for tough environments.There are a few common ways to cast Inconel:- Investment Casting: This method uses a wax model to form a ceramic mold, which is then filled with molten Inconel. It’s great for making detailed and complex shapes.

- Centrifugal Casting: Here, molten Inconel is poured into a spinning mold, forcing the metal to the edges, which works well for making pipes and other cylindrical parts.

- Vacuum Casting: In this process, Inconel is melted in a vacuum chamber to prevent contamination and imperfections, resulting in a cleaner finish.

The Common Material of Inconel Casting

- Inconel 600: Known for resisting heat, corrosion, and oxidation, it’s commonly used in environments prone to oxidation and chloride stress.

- Inconel 625: Highly resistant to seawater, acids, and other harsh environments, making it perfect for marine and chemical applications.

- Inconel 713C: Designed for gas turbines, this alloy excels in oxidation, corrosion, and thermal fatigue resistance—ideal for turbine blades and other high-stress components.

- Inconel 718: This high-strength alloy is valued for its ability to resist creep at high temperatures and is often used in aerospace turbine blades and structural components.

The Advantages of Inconel Casting

Inconel casting offers several benefits due to the unique properties of the alloy:

Inconel casting offers several benefits due to the unique properties of the alloy:- High-Temperature Strength: Inconel retains its strength even in extreme heat, making it perfect for applications like gas turbines and aerospace engines.

- Corrosion Resistance: It stands up well against corrosive gases, acids, seawater, and harsh chemicals, maintaining performance in tough environments.

- Creep Resistance: Inconel resists creep, or gradual deformation under high temperatures, which is key for long-term use in high-stress settings like turbine blades.

- Fatigue Strength: It can handle repeated stress and vibrations without cracking, which is great for applications with dynamic loads.

- Weldability: Inconel can be welded easily, allowing for complex structures and repairs.

- Excellent Mechanical Properties: It combines high tensile strength, ductility, and toughness for reliable performance.

- Low Thermal Expansion: Inconel expands less when exposed to heat, reducing the risk of thermal stress and distortion.

- Versatility: It can be cast into various shapes and sizes, making it ideal for custom-engineered components.

The Application of Inconel Casting

- Aerospace: Inconel is a go-to for gas turbine engines, exhaust systems, turbine blades, and other parts that need to handle intense heat and pressure.

- Power Generation: Inconel is used in gas and steam turbines, nuclear power plants, and high-temperature furnace parts. Its resistance to oxidation and creep ensures durability in these demanding systems.

- Chemical Processing: The alloy’s corrosion resistance makes it perfect for reactors, piping, valves, and heat exchangers where harsh chemicals and high heat are common.

- Oil and Gas: Inconel is used in downhole tools, wellhead equipment, valves, and pumps to handle high pressure, high temperature, and corrosive environments.

- Marine: Its resistance to seawater corrosion makes Inconel ideal for propellers, shafts, valves, and fittings on ships and submarines.

- Petrochemical: Inconel is a staple in aggressive chemical environments, used for reactors, furnace parts, and heat exchangers in high-temperature applications.

- Automotive: High-performance parts like turbochargers and exhaust systems benefit from Inconel’s strength in extreme temperatures, improving engine efficiency.

Other Processing Methods Suitable for Inconel

- Forging: Refines the grain structure, enhancing material properties.

- Rolling (Hot and Cold): Hot rolling improves malleability, while cold rolling boosts strength and finish.

- Extrusion: Produces pipes and structural shapes with consistent cross-sections.

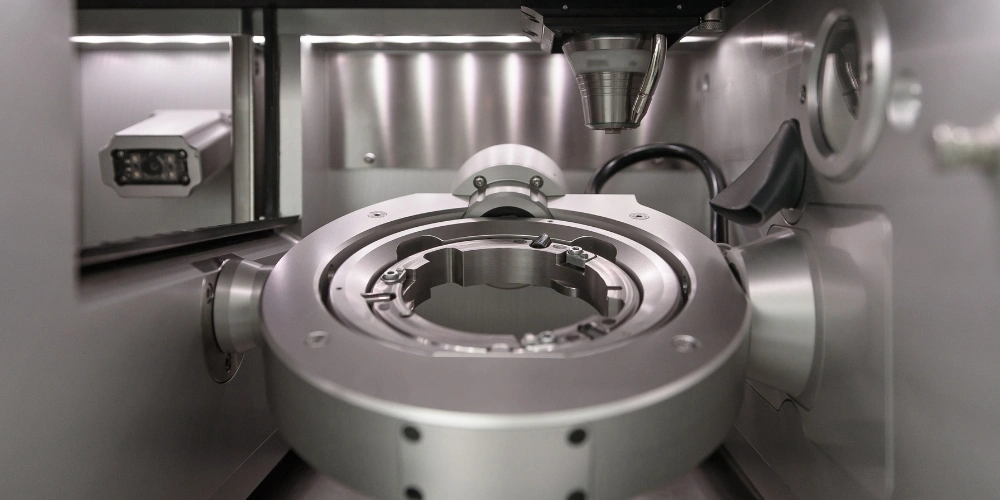

- Machining: Requires specialized tools to handle Inconel’s hardness and toughness.

- Powder Metallurgy: Melts powdered metal to create complex shapes and structures.

- Additive Manufacturing (3D Printing): Enables the production of intricate designs that traditional methods can’t achieve.

- Welding (TIG, MIG): Ideal for handling Inconel’s high heat requirements while reducing cracking.