Steel pipe hinges, often overlooked but crucial in construction and manufacturing, play a significant role in ensuring the smooth operation of doors, gates, and various other structures. In this article, we will delve into the world of steel pipe hinges, exploring their definition, advantages, types of steel suitable for manufacturing, finishes available, common applications, factors to consider when choosing, installation and maintenance tips, and the possibilities offered by custom steel pipe hinges.

What is a Steel Pipe Hinge

A steel pipe hinge is a type of hinge primarily crafted from steel, featuring a design characterized by a cylindrical or tubular shape resembling a pipe. In this configuration, the cylindrical component serves as the pivotal point around which connected objects rotate. The design and features of a steel pipe hinge can vary depending on its intended application and the specific requirements of the structure or system in which it is employed.

Advantages of Steel Pipe Hinges

Steel pipe hinges offer several advantages in various applications due to their robust and durable nature. Here are some of the key advantages:

- Strength and Durability: Withstanding heavy loads and ensuring long-lasting performance.

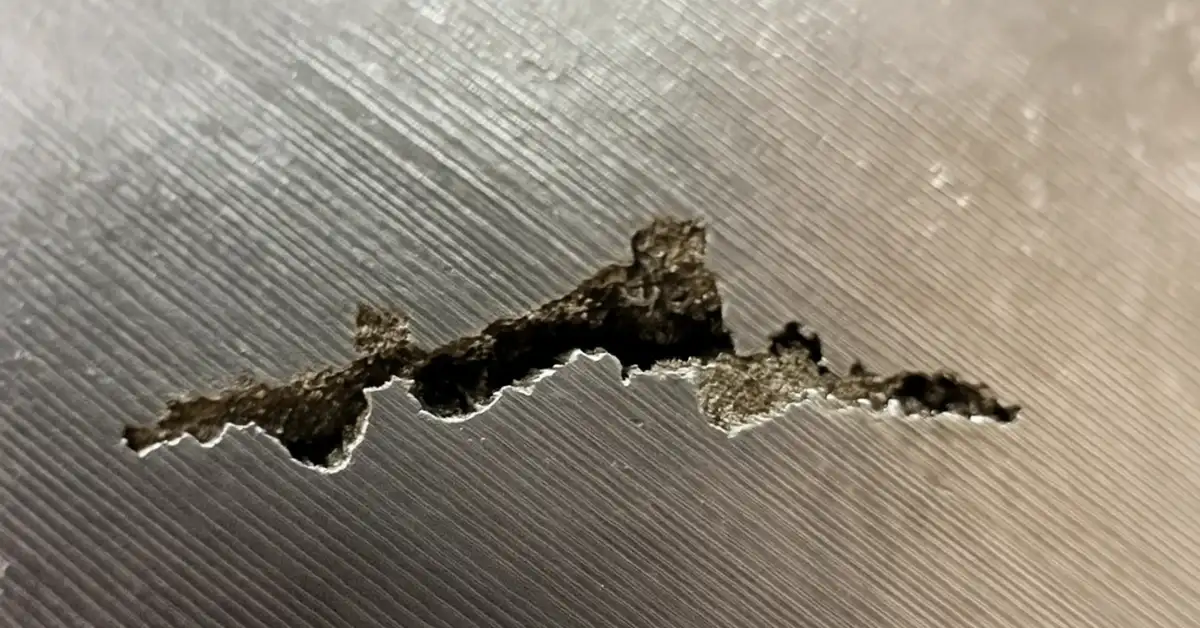

- Corrosion Resistance: Treated to prevent rust, extending lifespan, and suitable for diverse environments.

- Versatility: Adaptable for a wide range of applications in various industries.

- High Load-Bearing Capacity: Able to support heavy weights without bending or breaking.

- Low Maintenance: Resistant to corrosion and wear, requiring minimal upkeep.

- Temperature Resistance: Can withstand extreme temperatures without compromising structural integrity.

- Ease of Fabrication: Easily molded into different shapes and sizes for customization.

- Cost-Effectiveness: Initial higher cost offset by durability and reduced long-term maintenance expenses.

Types of Pipe Hinge

Pipe hinges come in various forms and are typically used for connecting cylindrical objects due to their adaptable nature. Here are common types of pipe hinges:

Clamp-on Pipe Hinge:

Clamp-on pipe hinges are designed to be easily attached to a pipe or post without the need for welding. They typically consist of two halves that can be clamped around the pipe and secured in place.

Weld-on Pipe Hinge:

Weld-on Pipe Hinges feature a simple structure, typically comprising two hollow metal tubes of the same diameter—one long and one short. When selecting, ensure that the diameter of the metal tubes precisely fits the pipe intended for installation. The longer section is placed onto the pipe, serving as the rotation point for the door or other connected pipes to be welded onto it. The shorter section is welded onto the installation pipe or steel post, providing support for the longer metal tube and preventing slippage.

Double Pipe Hinge:

The double-barrel hinge is a uniquely designed connecting device composed of two hollow metal tubes that can rotate around a common pivot point. This hinge is suitable for connecting components or structures that require flexible rotation. Its special design allows the two connected objects or components to swing freely around the pivot point, enabling a more flexible opening and closing movement.

Types of Steel Suitable for Pipe Hinge

The type of steel suitable for pipe hinges depends on the specific requirements of the application, including factors like load capacity, environmental conditions, and corrosion resistance. Here are some common types of steel used for pipe hinges:

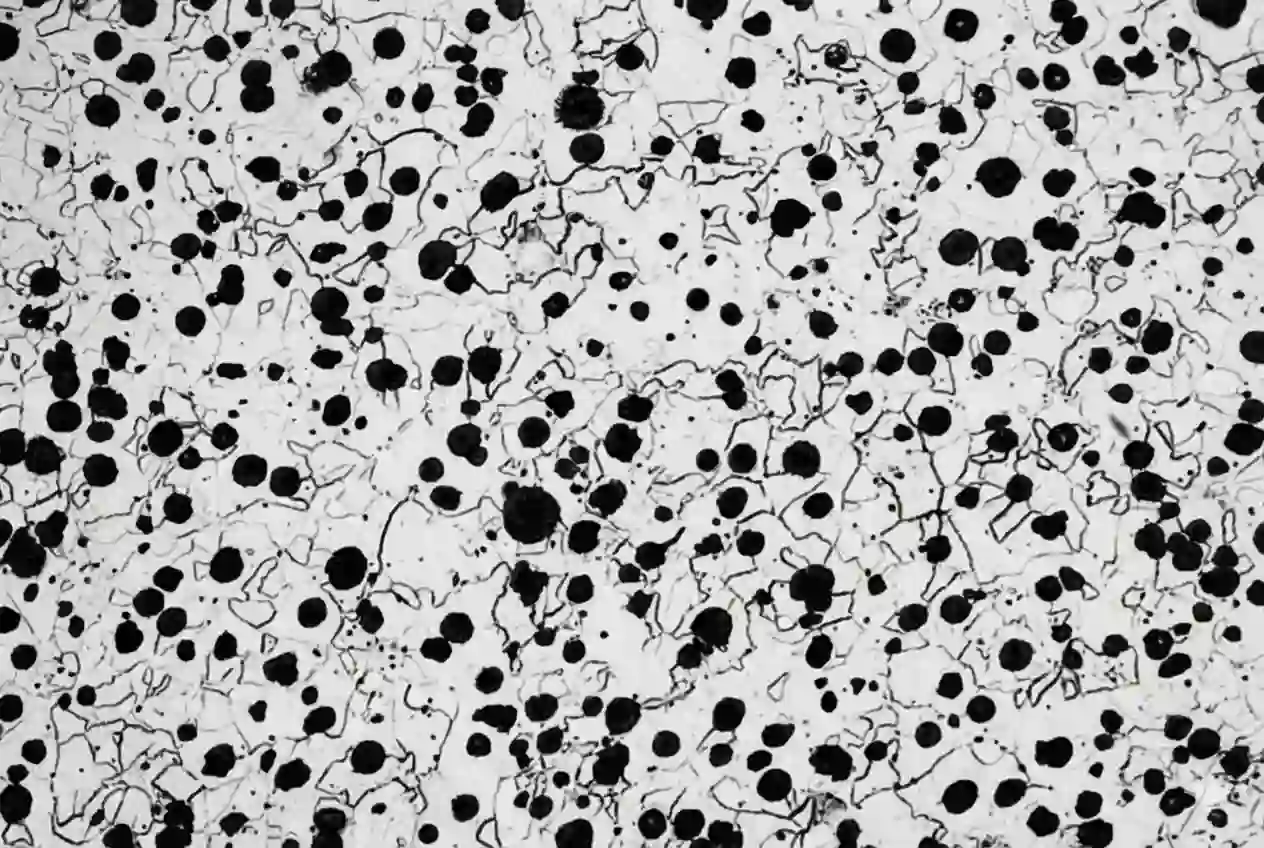

- Carbon Steel: Affordable and versatile, suitable for light to moderate-duty applications. Prone to corrosion, may require additional protection.

- Stainless Steel: Known for corrosion resistance, excellent for outdoor or corrosive environments. Available in grades like 304 and 316, with 316 being more corrosion-resistant.

- Alloy Steel: Made by combining elements to enhance specific properties. Suitable for heavy-duty applications where higher strength is required.

Finishes for Steel Pipe Hinge

Several finishes are available for steel pipe hinges, providing not only aesthetic appeal but also enhanced durability and corrosion resistance. Here are some common finishes for steel pipe hinges:

- Plain or Bare Steel: Natural finish, cost-effective but susceptible to corrosion.

- Galvanized Finish: Coated with zinc for corrosion resistance, ideal for outdoor use.

- Powder Coating: Durable, attractive finish offering protection against corrosion and abrasion. Customizable in various colors.

- Painted Finish: Corrosion-resistant paint for both protection and aesthetics.

- Stainless Steel Finish: Natural finish of corrosion-resistant stainless steel.

- Black Oxide Finish: Chemical process creating a black, magnetite layer for mild corrosion resistance and a sleek appearance.

- Antique/Rustic Finishes: Treatments for a traditional or aged look.

When selecting a finish for steel pipe hinges, consider the environmental conditions, the desired aesthetic, and the level of corrosion resistance needed for the specific application. Additionally, regular maintenance and cleaning can help preserve the appearance and functionality of the hinges over time.

Common Applications

Pipe hinges find application in various scenarios due to their versatility and ability to facilitate movement or rotation. Here are some common applications of pipe hinges:

- Gates and Fences

- Farm and Ranch Gates

- Agricultural Equipment

- Greenhouses

In summary, steel pipe hinges are typically employed in outdoor settings where there is a need to bear substantial loads, and meticulous maintenance is not required.

Factors to Consider When Choosing Steel Pipe Hinges

Load Capacity

The load capacity of steel pipe hinges varies. It is essential to assess the weight requirements of the application to ensure proper functionality.

Material and Finish

Consider the environment and aesthetic preferences when choosing the material and finish of steel pipe hinges. Different coatings can enhance corrosion resistance and visual appeal.

Size and Dimensions

Selecting the right size and dimensions is critical for optimal performance. Consultation with a professional can help determine the most suitable hinge for a specific project.

Installation Requirements

Understanding the installation requirements is crucial for the longevity of steel pipe hinges. Proper alignment, lubrication, and regular maintenance contribute to their effectiveness.

Maintenance of Steel Pipe Hinge

Maintaining a steel pipe hinge is essential for its longevity and optimal performance. Regular inspections should be conducted to identify wear, corrosion, or damage, with a focus on tightening loose fasteners. Adequate lubrication is key to reducing friction and ensuring smooth movement, particularly in challenging environmental conditions. Keeping the hinge clean from debris and applying rust prevention measures, such as inhibitors and coatings, helps combat corrosion. Additionally, aligning components correctly, managing weight loads, and considering weather protection contribute to effective maintenance. In cases of significant wear or issues, professional inspection and repairs are recommended to ensure the hinge’s continued reliability in various applications.

Custom Steel Pipe Hinge

If you’re looking for custom steel pipe hinges from manufacturers, there are several steps you can take to ensure you get a product that meets your specific needs.

- Start by researching reputable manufacturers with a track record of producing high-quality custom hinges.

- Provide detailed specifications for your project, including dimensions, load capacity, and any specific features required.

- Collaborate closely with the manufacturer to discuss design options, materials, and finishing.

- Request samples or prototypes to evaluate the product before placing a larger order.

- Consider factors such as the manufacturing lead time, cost, and warranty offered by the manufacturer.

Communication and collaboration with the manufacturer are key to ensuring that the custom steel pipe hinges meet your expectations and are tailored to your application.

Conclusion

Steel pipe hinges are indispensable components in construction and manufacturing, offering durability, stability, and versatility. From choosing the right steel type to considering finishes and installation requirements, every aspect plays a crucial role in the hinge’s performance. As we continue to innovate and prioritize sustainability, steel pipe hinges will remain at the forefront of ensuring the smooth functionality of doors, gates, and machinery.