Overview

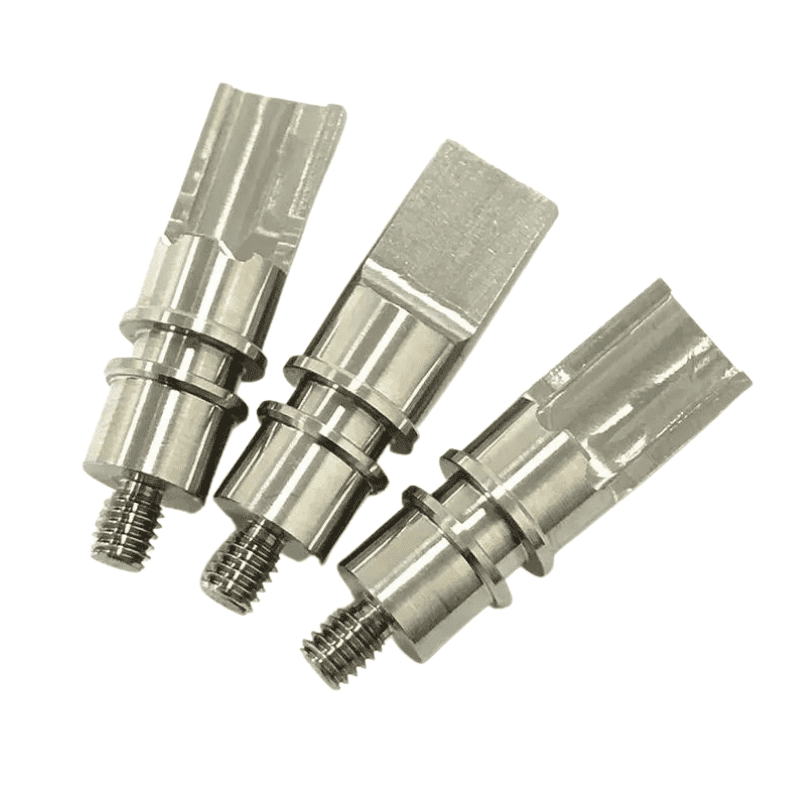

HDC has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your Titanium Grade 1 components to perfection, tailored to your specific requirements.

[toc]

What Is Titanium Grade 1?

Titanium Grade 1, unalloyed Ti (“Pure”) 35A alloy, It is ranked first in four commercially pure titanium grades. On account of its outstanding corrosion resistance. It has the lowest oxygen and iron level and is widely used in various applications. Such as heat exchangers, organism parts, low -temperature vessels, and more.

How Many Grades Does Non-Alloyed Titanium Have?

The commercially pure (CP) titanium is characterized by four main grades(CP1,CP2 and etc.), which are developed for individual purposes depending on the mechanical properties (e.g. strength, ductility, and formability). Grade 1 is the embodiment of extreme formability and corrosion resistance, making it the best choice for all applications in this category. Grade 2, widely known as the most versatile alloy, ensures an appropriate balance of strength, ductility and malleability. Strength grade 3 has the advantage of less formability than strength grade 2; this material is suitable for those requirements that have higher strength but are not ductility extreme. The last stage is Grade 4, used for the strongest one where high strength and moderate ductility are required. Such grades are determined by various applications, in which case titanium’s corrosion resistance serves as the main basis, and it is Grades 1 to 4 that define the basic categories of non-alloyed titanium.

What Is the Basis for Grading Titanium?

The grade of titanium is determined on the basis of its chemical composition, mechanical properties, microstructure, corrosion resistance, formability, weldability. The only difference between the commercial and the pure titanium grades is the percentage of the iron and oxygen. This in turns affects the strength and elasticity of the material. Alloyed grades, like the Grade 5 (Ti-6Al-4V), have the elements, like aluminum and vanadium, which make them stronger and have the other properties enhanced. The tensile strength, yield strength, ductility, and toughness that are balanced in real life applications are the basis of the grade selection, taking into account the manufacturing processes and environmental conditions. This scheme results in material accurate targeting to match the different application requirements, thus the performance and the cost factors are optimized.

What Limitations Does Titanium Grade 1 Have?

Titanium Grade 1, which has a high ductility and great corrosion-resistant properties, exhibits these limitations because of its low tensile strength. Hence, it is not applicable for the high-strength applications. Titanium grade 1 is also limited in terms of its mechanisms of performance at high temperatures and wearing resistance when compared to high-level titanium grades or alloyed versions, which may thus confine its application in situations that require higher mechanical properties or strong resistance to wearing. Moreover, as Grade 1’s high formability as well as welding capability are undoubtedly advantageous for some applications, it is necessary to evaluate the economic effectiveness of using a special material where such properties are not strictly needed. Therefore, Grade 1 titanium is most dominant for applications meant to exploit its unique features, such as corrosion resistance and formability, rather than for those requiring high strength.

Chemical Composition of Titanium Grade 1

| Chemical Element | % Present |

| Titanium, Ti | 99.1-100 |

| Iron, Fe | 0- 0.20 |

| Oxygen, O | 0-0.18 |

| Carbon, C | 0-0.01 |

| Nitrogen, N | 0-0.03 |

| Hydrogen, H | 0- 0.015 |

Do Other Elements in Titanium Grade 1 Affect Its Properties?

Grade 1 Titanium, which is also called as commercially pure titanium, is deliberately alloyed by way of adding measured (i.e controlled) amounts of interstitial elements such as oxygen, nitrogen, carbon, and hydrogen and substitutional impurities like iron. Indeed, these elements play a tiny role in the specifying of the properties. The alloying of ocysgen and nitrogen increases strength but keeps levels low to maintain ductility and formability. Carbon is limited to prevent carbide-forming thus keeping corrosion resistance and ductility in check. Hydrogen that leads to embrittlement, is also minimized, and bulk iron content is reduced to raise strength; nevertheless, it is kept low to maintain its softness and high formability. This does not mean that all grades of Titanium are better than the ones designed for use in highly corrosive environments; but rather maintain an acceptable balance between excellent corrosion resistance, ductility and formability that makes it suitable for applications where these properties are paramount.

Mechanical Properties of Titanium Grade 1

| Properties | Metric | Imperial |

| Hardness, Brinell | 120 | 120 |

| Hardness, Knoop | 132 | 132 |

| Hardness, Rockwell B | 70 | 70 |

| Hardness, Vickers | 122 | 122 |

| Tensile Strength, Ultimate | 240 MPA | 34800 psi |

| Tensile Strength, Yield | 170 – 310 MPa | 24700 – 45000 psi |

| Elongation at Break | 24% | 24 % |

| Reduction of Area | 35% | 35 % |

| Modulus of Elasticity | 105 GPa | 15200 ksi |

| Compressive Modulus | 110 GPa | 16000 ksi |

| Poisson’s Ratio | 0.37 | 0.37 |

| Charpy Impact | 310 J | 229 ft-lb |

| Shear Modulus | 45 GPa | 6530 ksi |

| Hardness, Brinell | 120 | 120 |

Physical Properties of Titanium Grade 1

Density | Mean Coefficient of Thermal Expansion | Melting Point | Thermal conductivity | Modulus of elasticity |

| 4.51g / cm³ | 4.78*10-5mm | 1670 °C | 111W / (mK) | 15656 MPa |

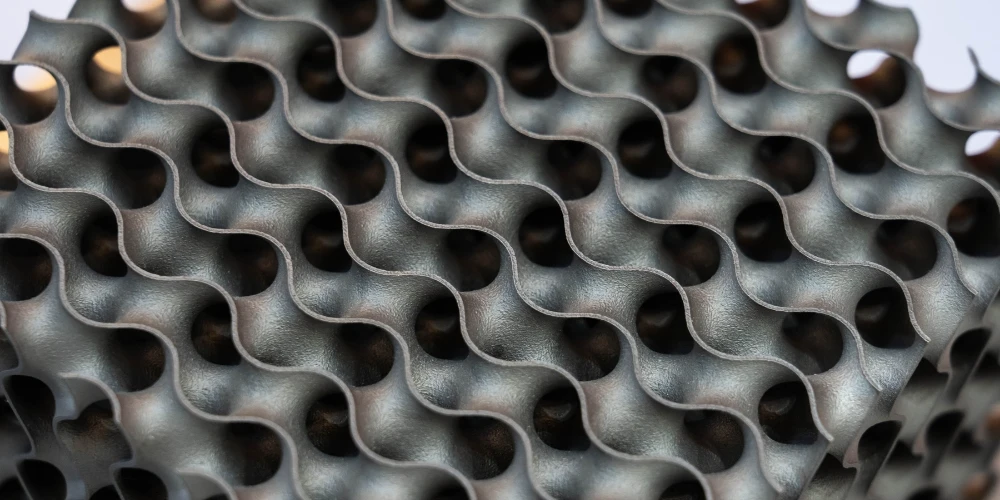

Challenges in Processing Titanium Grade 1

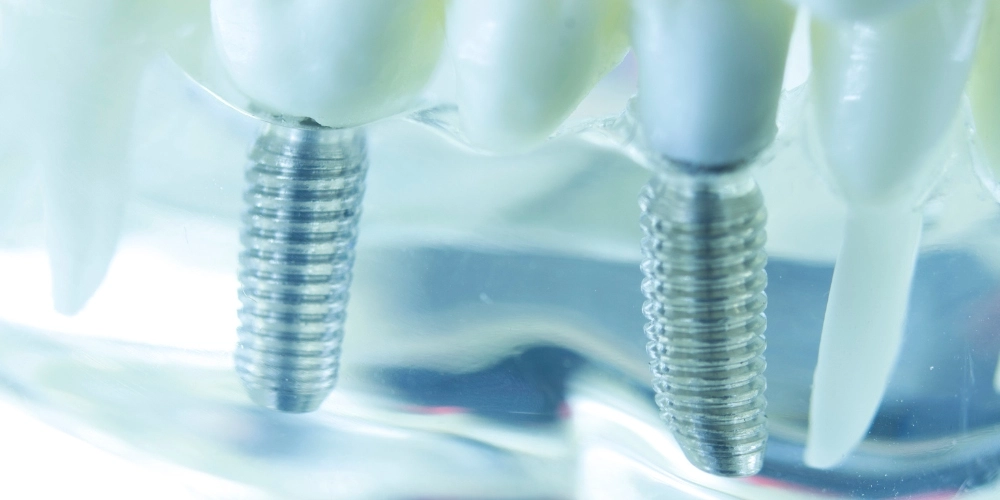

In the case of processing of Titanium Grade 1, these challenges arise due to the high reactivity, which makes it more sensitive to any contamination and its ductility, which complicates both machining and forming processes. These high-grade parts are designed with strict environmental controls in mind to minimize properties degradation and with own machining tools usage in mind to handle their adhesion to the tools and cause wear. It is vital that controlled environments are maintained during welding and heat treatments, and the material is handled with care so that it does not lose integrity during forming, which all makes the production more costly. However, these difficulties do not discount the fact that TiGrade 1 possesses high-end corrosion properties as well as biocompatibility, thus, it is used extensively in demanding applications, such as chemical processing, marine and medical.

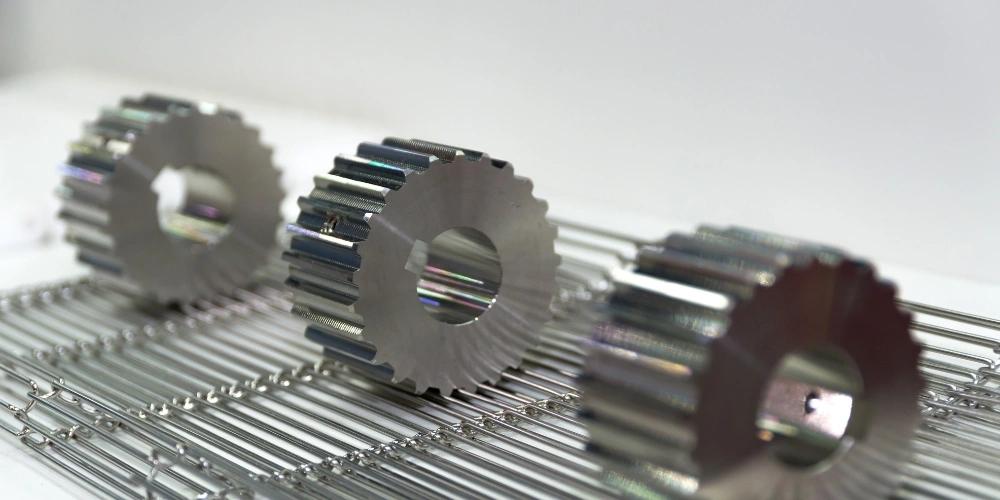

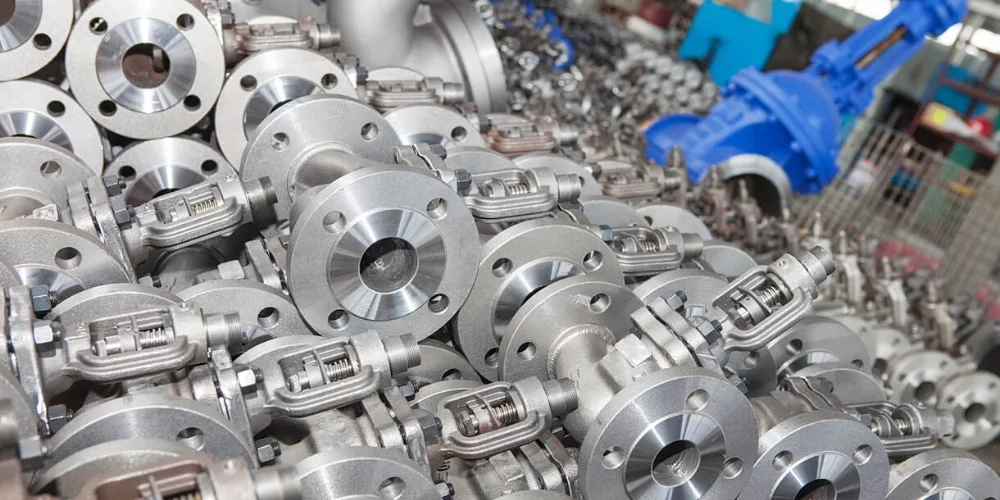

Applications of Titanium Grade 1

The Grade 1 of Titanium is used in a lot of industries as it is quite resistant to corrosion, has a good formability and is welding friendly. Used in the chemical processing industry to construct items such as heat exchangers and reactors, it has invariable corrosion resistance for corrosive substances. Its seawater corrosion resistance makes it good for using it for marine applications such as construction of ships and offshore platforms. Although corrosion-resistant Grade 1 is the choice for structural aerospace components, the higher-grade and alloys find important niche applications in aerospace engineering. Its biocompatibility is a key characteristic required for medical implant devices such as orthopedic devices. Also it is a part of the power generation and in such processes as geothermal and nuclear power type, which are prone to corrosion inside the reactor and it is also a part of a construction for its durability and aesthetics. In addition, the component’s durability sheds light on the applicability of these membranes in applications that focus on resilience to environmental challenges.