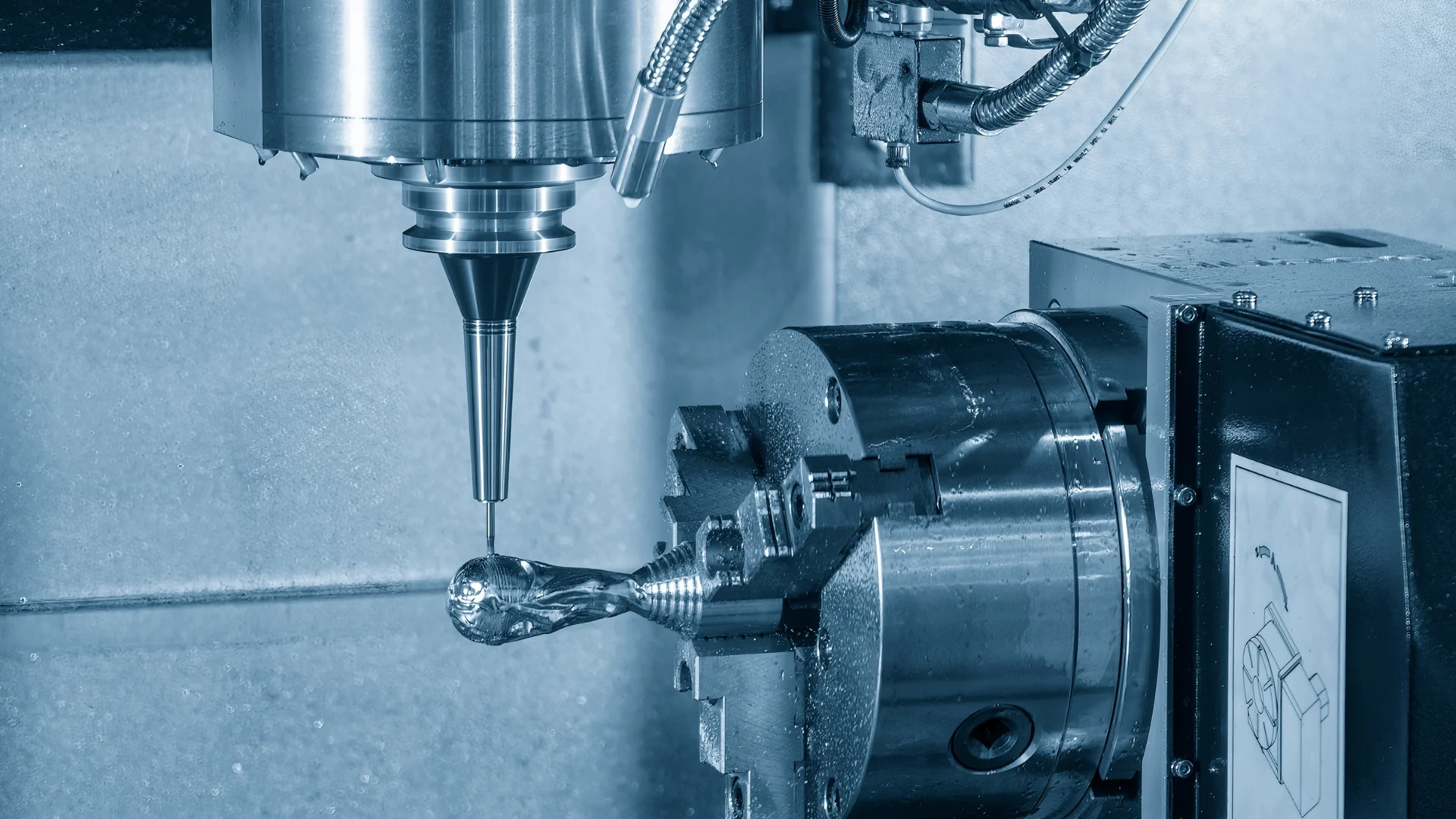

5 Axis CNC Machining Services

HDC Manufacturing offers industry-leading 5 axis CNC machining services tailored for precision and efficiency. Our state-of-the-art 5 axis CNC machines allow for complex geometries and intricate designs, making us a preferred choice for various applications.

Advantages of HDC Manufacturing

Understand the key benefits of choosing HDC Manufacturing for your 5 Axis CNC machining needs, including precision and efficiency.

Precision

CNC milling machines are capable of producing parts with extremely tight tolerances, ensuring precise and consistent results.

Efficiency

With advanced CNC milling technology, manufacturers can create complex shapes and intricate designs that would be difficult or impossible to achieve with manual machining.

Versatility

CNC milling can rapidly produce parts, especially after the initial setup and programming, making it ideal for high-volume production runs.

Quality Control

CNC mills can work with a wide range of materials, including metals, plastics, and composites, providing flexibility across various applications.

Custom Solutions

The automation feature of CNC milling reduces the need for operator intervention, which minimizes errors and enhances the production efficiency.

Competitive Pricing

CNC milling is precise and typically generates less material waste compared to other manufacturing processes, which can be more cost-effective and environmentally friendly.

Why Choose HDC Manufacturing

HDC Manufacturing proudly offers cutting-edge 5 Axis CNC machining services designed to meet the demanding needs of various industries. Our advanced 5 axis CNC machines provide unparalleled precision and versatility, allowing us to produce intricate parts and components with exceptional accuracy.

With a commitment to innovation, HDC leverages the latest technology in 5 axis machining to deliver custom solutions tailored to our clients’ specifications. Our expertise ensures that even the most complex geometries can be efficiently machined, minimizing lead times while maintaining high quality. Trust HDC for your 5 axis CNC machining needs, where precision meets excellence.

Materials We Work With 5 Axis Machining

Review the variety of materials we utilize to ensure optimal performance in your machining projects.

Stainless Steel

Available grades include 304 and 316, perfect for customers needing excellent corrosion resistance and durability. Common applications include automotive parts (exhaust systems and fuel tanks), marine hardware, and medical devices, where hygiene and strength are critical.

Aluminum Alloy

We offer various grades, including 6061 and 7075. Aluminum is ideal for customers seeking lightweight solutions with good mechanical properties. It’s commonly used in automotive modification parts (like chassis and brackets) and in aerospace applications for components that require both strength and reduced weight.

High-Temperature Alloys

We work with materials like Inconel 625 and Inconel 718. These alloys are ideal for customers in aerospace and energy sectors who need components that can withstand extreme conditions, such as gas turbine blades and structural components in high-stress environments.

Nickel-Based Alloys

We offer Inconel 600 and Monel 400 for customers requiring high-performance materials. Inconel 600 is suitable for chemical processing equipment, while Monel 400 excels in marine applications, providing excellent resistance to seawater and acidic environments.

Titanium Alloy

We provide titanium alloy, such as Ti-6Al-4V, for customers who seek high strength and corrosion resistance. This material is especially suited for automotive modification parts (engine components and suspension systems), motorcycle parts (swingarms and exhaust systems), and aesthetic applications like bike frames and pedals. We can also manufacture intricate components, such as impellers, with titanium.

Custom 5 Axis CNC Machining Process

Explore our step-by-step approach to delivering high-quality custom 5 Axis CNC machined parts.

1. Design and Planning

Review your design specifications; collaborate to optimize for manufacturability.

2. Material Selection

Choose the appropriate material (e.g., aluminum, titanium, high-temperature alloys) based on the design.

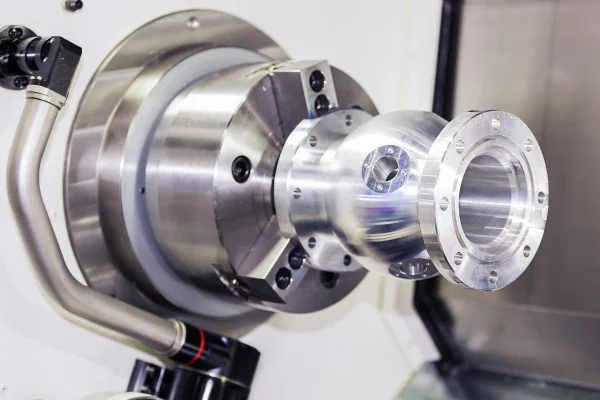

3. Setup and Calibration

Securely mount the material on the CNC machine and perform precise calibration to align with design specifications.

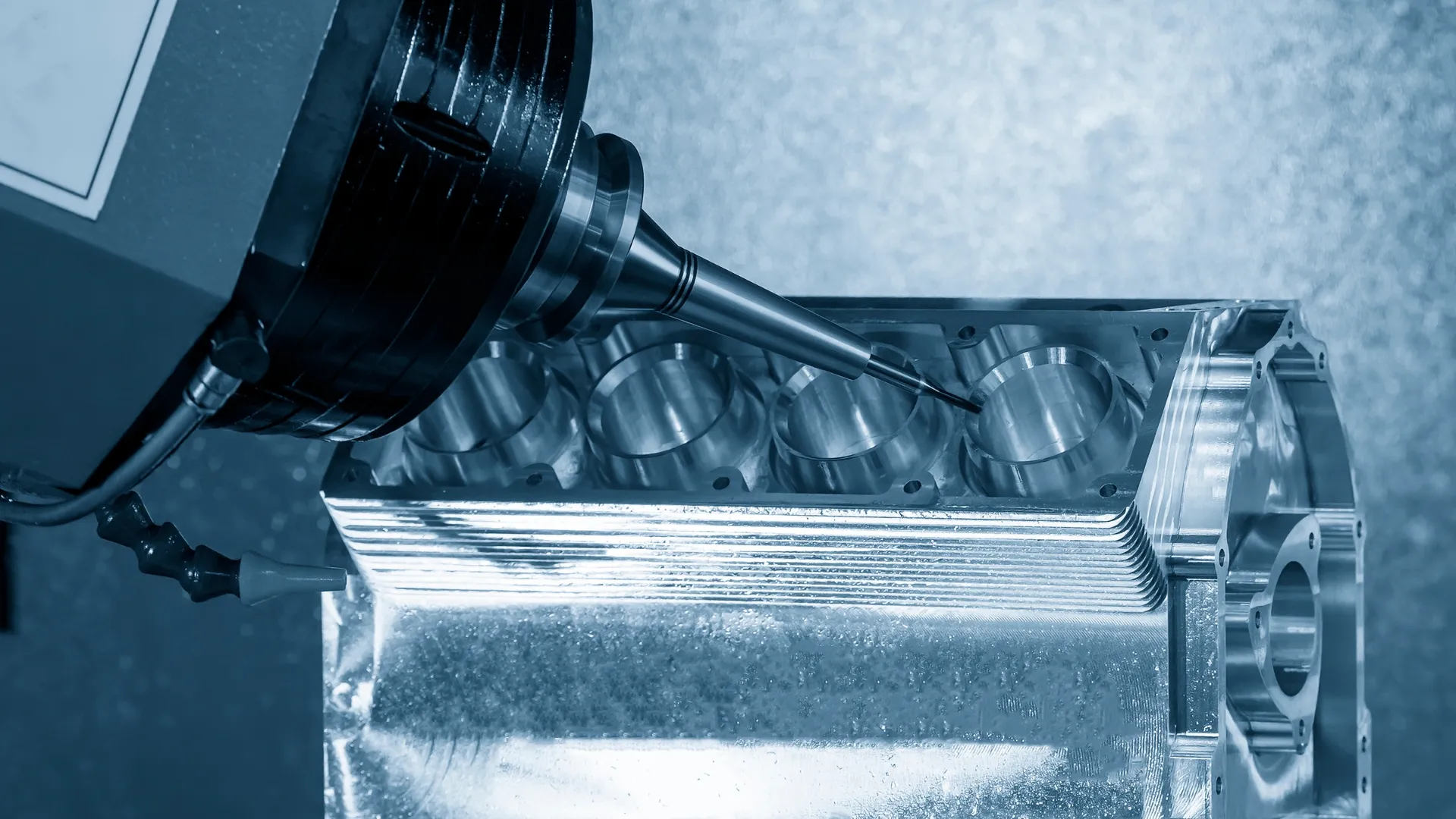

4. Machining Process

Begin machining with our advanced 5 Axis CNC center, allowing simultaneous movement for complex geometries.

5. Quality Control Checks

Implement real-time monitoring and periodic inspections to ensure dimensional accuracy throughout the process.

6. Finishing Touches

Apply necessary finishing processes, such as polishing or surface treatments, to enhance performance and appearance.

7. Final Inspection

Conduct a comprehensive inspection to verify all specifications and tolerances.

8. Packaging and Shipping

Carefully package components to prevent damage and ensure timely delivery to clients.

Industries We Serve

Learn about the diverse industries that benefit from our custom 5 Axis CNC machining solutions.

Automotive Industry

In the automotive industry, we create custom parts such as engine components, transmission housings, and suspension systems. Our ability to produce lightweight, high-strength parts helps enhance vehicle performance and efficiency.

Aerospace Industry

Precision is critical in aerospace applications. Our 5 Axis machining is used to manufacture complex components like turbine blades, structural parts, and intricate brackets that meet stringent safety and performance standards.

Medical Industry

The medical sector relies on precise machining for components such as surgical instruments, implants, and diagnostic devices. HDC’s expertise in 5 Axis CNC machining allows for the production of intricate and highly accurate parts that meet strict regulatory requirements.

Electronics Industry

CNC milling helps create intricately detailed components such as circuit boards, enclosures, and connectors, which are essential for the reliable functioning of electronic devices.

Manufacturing

From custom tooling to fixtures and molds, our machining services support various manufacturing processes. We provide the precision needed to produce high-quality components that enhance production efficiency.

Energy

HDC also serves the energy sector, producing components for renewable energy systems, such as wind turbine parts and components for power generation equipment. Our machining capabilities support the production of durable and efficient solutions.

FAQ

Find answers to your common questions about our 5 Axis CNC machining services, processes, and capabilities.

What is 5 Axis CNC machining?

5 Axis CNC machining allows for simultaneous movement along five axes, enabling the production of complex geometries with high precision. This technology is ideal for intricate parts in various industries.

What materials are compatible with 5 Axis CNC machining?

We work with a variety of materials, including aluminum, titanium, stainless steel, high-temperature alloys, and nickel-based alloys. Each material is chosen based on the specific requirements of the project.

How long does the 5 Axis machining process take?

Lead times vary based on the complexity of the project and the materials used. Generally, we provide an estimated timeline during the quoting process to keep you informed.

What industries benefit from 5 Axis CNC machining?

Industries such as aerospace, automotive, medical, and custom fabrication greatly benefit from our 5 Axis CNC machining services, enabling the creation of precision components.

How does HDC ensure quality in 5 Axis machining?

We implement strict quality control measures throughout the machining process, including real-time monitoring and periodic inspections to ensure that all components meet specifications.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact Us

Other Service We Provide

Explore HDC Manufacturing’s comprehensive range of services designed to meet diverse manufacturing needs.