Custom Die Casting Service, Global Trusted OEM Factory

One-stop die casting parts customization service, from mold design, quality control, to final finishes. Contact us and get an instant quote today.

- One-Stop Solution

- Competitive Price

- ISO Certified

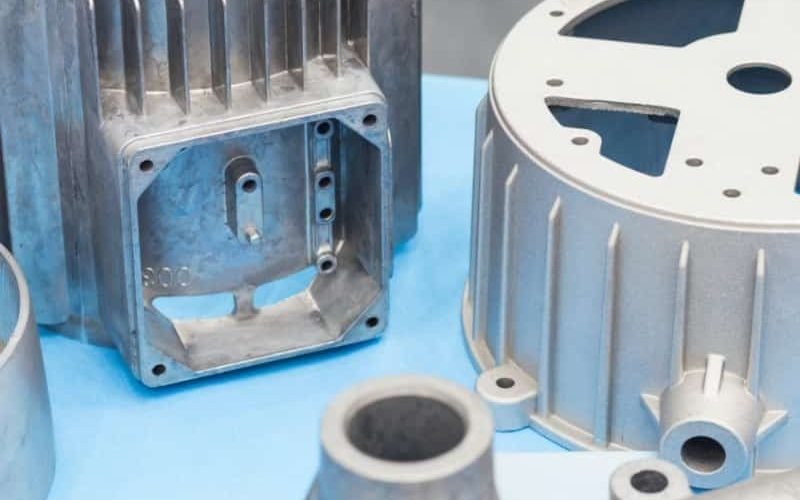

Die Casting Services

HDC Manufacturing offers both low-pressure and high-pressure die casting for different product requirements

Low-Pressure Die Casting (LPDC)

- Pressure range: 0.3 – 1 bar

- Complex thin-wall molding capabilities

- Smooth metal filling, very low porosity

- Near-net shape, mechanical properties close to forgings

Learn More

High-Pressure Die Casting (HPDC)

- Pressure range: 150 bar – 1500+ bar

- Excellent thin-wall and fine-feature forming capability

- Extremely high cycle speed, mass production

- High surface finish, outstanding dimensional accuracy

Learn More

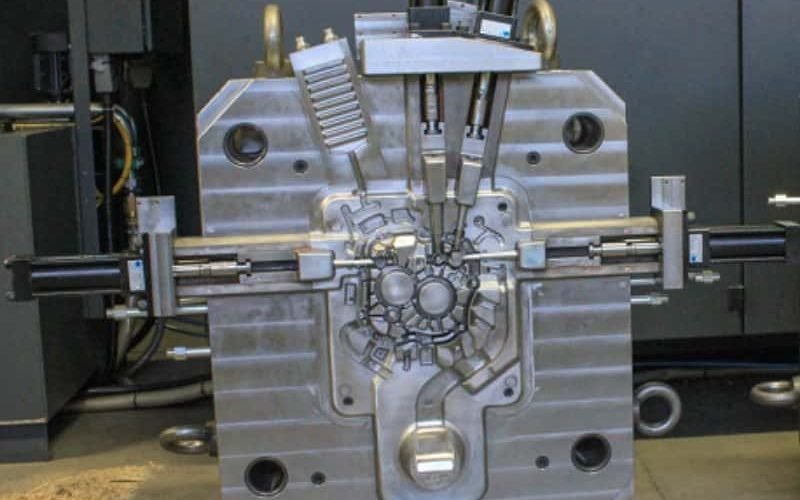

Mold Design and Fabrication

- 10 experienced engineers, capable of designing and optimizing die casting molds.

- Complex geometry and thin wall structure are achievable

- Manufacturing molds in our factory with advanced 4 axis and 5 axis CNC machines.

Learn More

Materials & Surface Treatment

Customize any die casting parts with our comprehensive materials and surface treatment options

Die Casting Materials

Surface Treatment

Electroplating

Zinc, chrome, and nickel plating for better corrosion resistance

Sand/Bead Blasting

Remove burrs and surface defects, creating a matte texture

Anodizing

Mainly used for aluminum castings, hard anodizing available

Painting

Spray paint and powder coating for a durable finish

Have Different Material or Finish Needs?

Relying on the Institute of Metal Research, Chinese Academy of Sciences, HDC Manufacturing provides you with the best solutions in casting process, material analysis and configuration, heat treatment technology, etc

Industry We Serve

One-stop custom die casting solutions, tailored for different industries

Automotive

Die casting can efficiently produce automotive engine housings, transmission components, body structural parts and chassis parts to achieve lightweight and complex structures.Electronics

Die-casting and manufacturing precision mobile phone/computer shells, middle frames, internal brackets and radiators to meet the needs of lightweight, high strength and electromagnetic shielding.Home Appliances

Die casting is used to produce durable shells, internal structural supports, and critical transmission components for home appliances such as air conditioners, refrigerators, washing machines, ensuring strength and dimensional accuracy.Communication

Die-casting large-scale manufacturing of heat dissipation shells, shielding covers and structural frames for communication equipment (base stations, routers, switches) to ensure good heat dissipation, stability and electromagnetic compatibility.Energy

Die-casting is used in the production of photovoltaic inverter shells, new energy vehicle charging pile components, motor shells and energy storage equipment structural parts and other application scenarios that require high protection level and excellent heat dissipation.

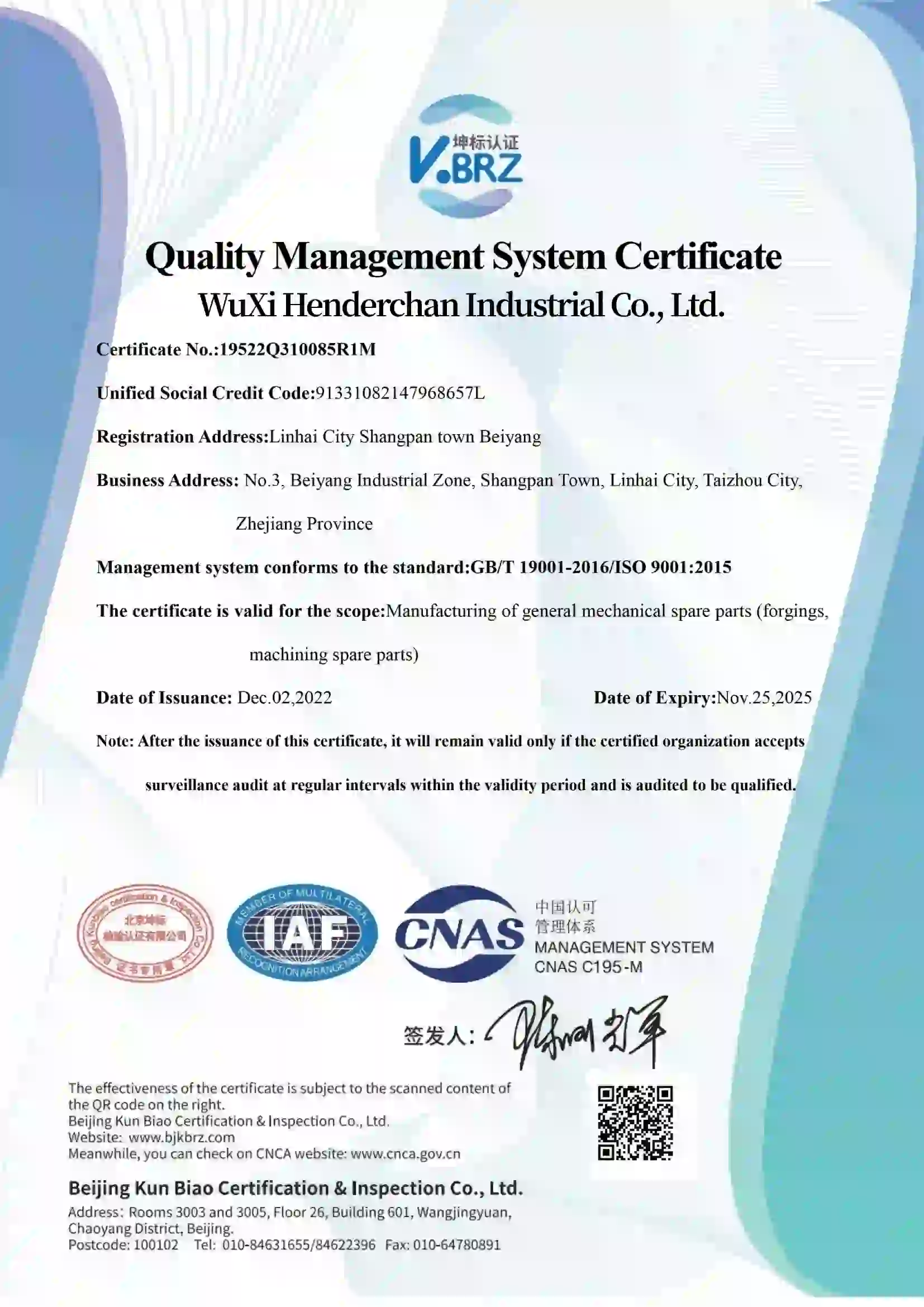

Die Casting Quality Control

As a certified manufacturer, we employ strict quality control from the material, processing, to the final products, making sure every part meets your quality requirements.

We are certified by:

✓ AS9100

✓ ISO 14001:2015

✓ ISO 9001:2015

Ensuring certified alloys meet strict specifications before melting.

Continuously controlling critical parameters during every casting cycle.

Utilizing CMM and X-ray for precise measurements and defect detection.

Validating every part against customer requirements before shipment.

Why Choose HDC Manufacturing

Over 10 years of casting excellence delivering superior components worldwide

One-Stop Solution

- Capable of mold design and optimization

- In-house mold manufacturing and testing

- Custom material and finishes are available

- Support from design, fabrication, to shipping

Advanced Equipment

- Latest die casting machine from 400 to 3,500 tons, large parts are achievable

- CMM(Coordinate Measuring Machine)

- Tensile strength and hardness tester

Global Service

- Multi-language technical support

- Compile with international quality standards

- Air, sea, rail, and express

- T/T, L/C,D/P, and Paypal supported

Competitive Pricing

- Mature supply chain, get high quality material with lower cost

- Take advantage of large-scale production

- Continuously optimize production processes

Custom Service Workflow

Our streamlined custom die casting parts process guides you from initial consultation to final delivery

1. Request a Quote

Provide drawings or samples, our engineers will provide you with professional technical solutions and quotations within 24 hours

2. Solution Confirmation

Confirm the technical scheme, material specifications, surface treatment requirements, sign the contract and arrange the production

3. Mold Manufacturing

Professional mold design and manufacturing, using high-quality mold steel to ensure mold accuracy and service life

4. Sample Confirmation

Provide samples for quality and function testing before mass production, ensure the product quality meets your requirements

5. Production

Large-scale production, strict quality control, regular progress reporting to ensure on-time delivery

6. Inspection and delivery

Full quality inspection, packaging and delivery, provide complete quality report and certificate of conformity

More About HDC Manufacturing

Check our certifications and equipment list to get more information about HDC Manufacturing.

| Equipment | Specifications | Quantity |

|---|---|---|

| Melting Furnaces | – | 6 |

| Cold Chamber Machines | 400T – 3,500T | 11 |

| Hot Chamber Machines | 50T – 800T | 6 |

| CNC Machining Centers | 3/4/5-Axis | 10 |

| Trimming Presses | – | 6 |

| Shot Blasters | – | 5 |

| CMM Machines | – | 2 |

| X-ray Inspectors | – | 2 |

| Spectrometers | OES Type | 2 |

| Heat Treatment Lines | – | 1 |

Material Comparison Table

A comprehensive comparison table for the four types of commonly used alloys, helps you make a wise choice when choosing a material

| Evaluation Dimension | Aluminum Alloy | Zinc Alloy | Magnesium Alloy | Copper Alloy |

|---|---|---|---|---|

| Density (g/cm³) | 2.7 | 6.6 | 1.8 | 8.9 |

| Melting Point (°C) | 580-650 | 385-400 | 600-650 | 900-1100 |

| Fluidity | ★★★★☆ (Excellent) | ★★★★★ (Exceptional) | ★★★☆☆ (Good) | ★★☆☆☆ (Poor) |

| Mold Life (k shots) | 150-300k | 500-1000k+ | 100-200k | <5k (Extremely Low) |

| Tensile Strength (MPa) | 220-320 (ADC12/A380) | 280-330 (Zamak 5) | 230-280 (AZ91D) | 350-450 (Silicon Brass) |

| Ductility | ★★☆☆☆ (3-5%) | ★★★★☆ (10-15%) | ★★★★☆ (6-10%) | ★★★☆☆ (8-12%) |

| Corrosion Resistance | Moderate (requires anodizing) | Poor (avoid acidic environments) | Very Poor (mandatory surface treatment) | Excellent (inherent) |

| Machinability | ★★★★☆ (Easy machining) | ★★★★★ (Exceptional) | ★★★★☆ (Good) | ★★☆☆☆ (Rapid tool wear) |

| Cost Index | 1.0 (Baseline) | 1.2 (material + mold) | 2.5 (material + protection) | 5.0+ (material + mold loss) |

| Min. Wall Thickness (mm) | 0.8-1.5 | 0.5-1.0 | 1.0-1.5 | ≥3.0 |

| Surface Treatment Compatibility | Anodizing/Spraying/Plating | Plating/Spraying (Optimal) | Micro-arc oxidation/Spraying | Passivation/Plating (difficult) |

What is Die Casting

Die casting involves using pressure to push the molten metal into the cavity of a mold made of metal. Then the metal fills the cavity, cools down, and forms a duplicate of this cavity, which is made according to the final part that is desired. This manufacturing process creates highly accurate, detailed metal parts with excellent surface finishes and dimensional consistency.

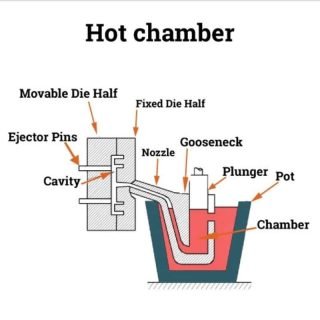

Types of Die Casting

Die casting can be categorized based on two aspects. The first aspect is how the metal is injected into the mold:

- Hot Chamber Die Casting(Gooseneck Casting): Dip the gooseneck tube directly into the molten metal, and direct injection through hydraulic cylinders.

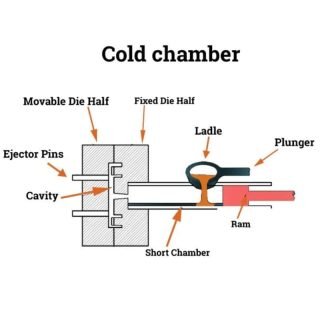

- Cold Chamber Die Casting: The molten metal is scooped into the injection chamber by a manual/robotic arm, and the piston pushes the metal horizontally for injection

The second aspect is the metal injection pressure:

- Low Pressure Die Casting (LPDC): 0.01~0.1 MPa

- High Pressure Die Casting (HPDC): 40~150 MPa

How to Choose Die Casting

If you’re not a die casting professional, choosing the right casting method can be confusing. As a professional die casting factory, we know what is holding you back, and it’s our responsibility to offer assistance.

The main consideration when choosing the right die casting methods lies in three points:

- Material Type

- Parts Size and Weight

- Structure Requirements

Here’s a clear selection flow we made, and you can quickly figure out the best process for your custom die casting project by following it.

FAQs

Get answers to frequently asked questions about people seeking to collaborate with HDC Manufacturing for custom die-casting parts

Can HDC design and manufacture molds?

Yes, with our professional engineers and in-house 4-axis and 5-axis CNC machines, we can design and manufacture die casting molds for any application.

Do I need to pay for the mold, and how much is it?

Yes, depending on the design complexity and fabrication difficulty, a mold can cost from hundreds to thousands of dollars. We need drawings or samples to evaluate the mold fee.

Does HDC have an MOQ for die casting parts?

Yes. An MOQ is needed, but the specific quantity can be different from tens to thousands. Please contact us and provide details so we can give you a concrete number.

Can HDC offer material certifications and test reports?

Yes, we source raw material from the best supplier in China, and every batch comes with certification. We can also test chemical composition and crucial physical properties with our advanced testing equipment.

Can HDC provide prototypes before large production?

Of course, it’s a standard procedure to provide prototypes for quality approval and function verification.

How do I pay for the order?

For more information, please click this link for details.

Get a Quote Today

Get a quick quote by filling out this form. Our sales team will get back to you within 24 hours.