- Home

- Capabilities

- Metal Bending Service

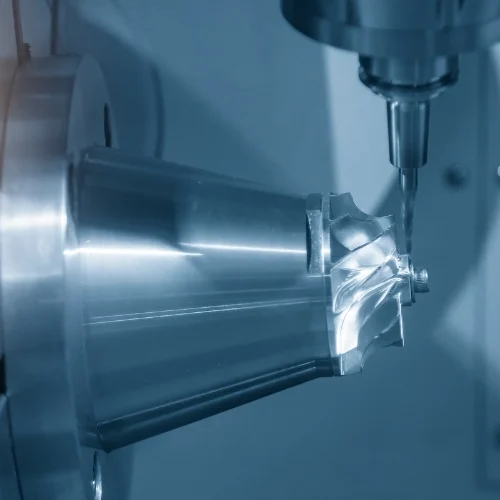

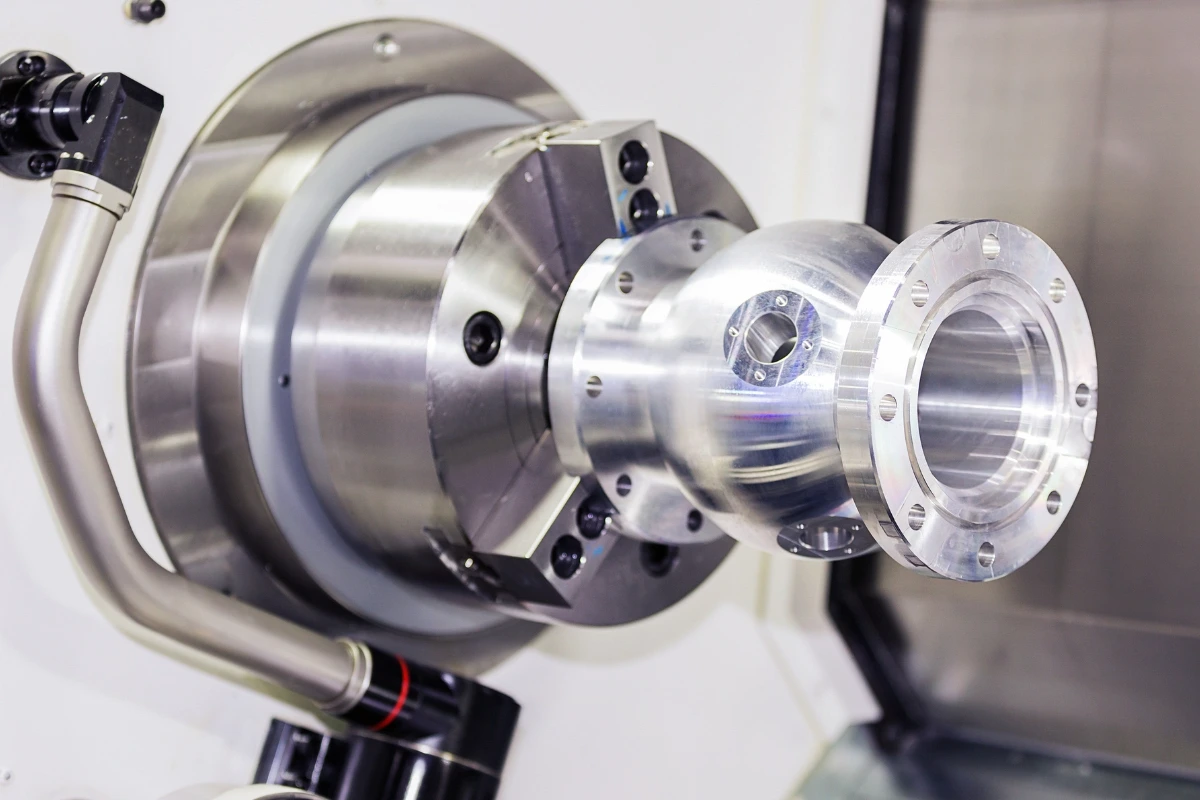

Precision Sheet Metal Bending Services

At HDC, we deliver high-quality, custom sheet metal bending solutions tailored to your unique needs. From automotive to aerospace, our state-of-the-art technology and skilled team ensure precision, efficiency, and exceptional results for every project.

Why Choose HDC for Custom Sheet Metal Bending

Explore the benefits of leveraging HDC’s sheet metal fabrication to enhance your manufacturing processes, ensuring quality and efficiency.

Materials Available for Bending

HDC works with a wide range of materials, including aluminum, stainless steel, carbon steel, and more, to meet your custom bending needs.

Brass

- Thickness: 0.5 mm to 5 mm

- Finishes: Polished, brushed, or coated

- Special Requirements: Must be handled carefully to avoid tarnishing; commonly used in decorative applications and electrical fittings.

Aluminum

- Thickness: 0.5 mm to 6 mm

- Finishes: Anodized, painted, or mill finish

- Special Requirements: Must be selected based on alloy type for optimal bending; typically used in aerospace and automotive applications.

Stainless Steel

- Thickness: 0.5 mm to 10 mm

- Finishes: Brushed, polished, or passivated

- Special Requirements: Requires specific handling to prevent scratching; commonly used in food processing and medical applications due to its hygienic properties.

Carbon Steel

- Thickness: 1 mm to 12 mm

- Finishes: Galvanized, painted, or untreated

- Special Requirements: May require post-bending treatment to prevent rust; ideal for structural and construction applications.

Custom Sheet Metal Bending Process

At HDC, we follow a meticulous step-by-step process to ensure precision, quality, and efficiency in every sheet metal bending project.

Consultation & Design Review

We start by understanding your project requirements and reviewing designs to ensure feasibility and precision.Material Selection

Our experts help you choose the right material (e.g., aluminum, stainless steel) to meet performance and aesthetic needs.Setup & Programming

Using advanced CNC technology, we program the machines for accurate bending angles and dimensions.Bending Operation

Skilled operators execute the bending process, closely monitoring to ensure precision and consistency.

Quality Control

We conduct dimensional checks and visual inspections to ensure every component meets our high standards.Finishing Touches

Additional processes like deburring, polishing, or coating are applied as needed to enhance durability and appearance.Final Inspection

A thorough final inspection ensures all parts meet your specifications and quality requirements.Delivery

We package and ship your components safely and on time, guaranteeing satisfaction with every order.

Industries We Serve

Automotive

Aerospace

Construction

Custom Fabrication

Marine

Precision of HDC Sheet Metal Bending

This table outlines the precision metrics of HDC's metal bending services, demonstrating our strict quality control and professional standards.

| Bending Type | Precision Range | Description |

|---|---|---|

| Angle Precision | ±0.5° | Ensures each bend angle meets design specifications. |

| Length Precision | ±0.1 mm | Guarantees accurate length after cutting and bending. |

| Material Thickness Precision | ±0.05 mm | Controls consistency in material thickness to avoid errors. |

| Bend Radius Precision | ±0.2 mm | Ensures the bend radius conforms to design specifications. |

| Surface Finish | Ra 1.6 µm (or better) | Provides high-quality surface treatment, reducing imperfections. |

| Repeatability Precision | ±0.1 mm | Maintains consistency in high-volume production. |

FAQs

Our lead times vary based on the complexity and volume of the project. Generally, we aim for a turnaround of 2 to 4 weeks. For urgent requests, please contact us to discuss expedited options.

We can bend a variety of materials, including aluminum, stainless steel, carbon steel, and brass. Each material has its specific properties that we consider to ensure optimal results.

We utilize advanced CNC bending machines and implement strict quality control measures throughout the process. This ensures that every bend meets the specified tolerances and design requirements.

Absolutely! We specialize in custom solutions tailored to your specific needs. Our team works closely with clients to understand their requirements and deliver bespoke bending services.

The thickness we can bend varies by material:

- Aluminum: 0.5 mm to 6 mm

- Stainless Steel: 0.5 mm to 10 mm

- Carbon Steel: 1 mm to 12 mm

- Brass: 0.5 mm to 5 mm

Yes, we provide additional services such as finishing, coating, and assembly to enhance the performance and appearance of your bent components.

To receive a quote, please contact us with details about your project, including material type, dimensions, and any specific requirements. You can also upload any relevant design files for better accuracy.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!