Expert Sand Casting Solutions

We offer professional and flexible sand casting services to meet your diverse metal part casting needs, ranging from simple to complex, small to large batches, and standard to high precision requirements.

- Wide Range of Material

- Multiple Casting Processes

- Value-Added Services

Sand Casting Services

Versatile and flexible sand casting processes, precisely tailored to your project needs

Green Sand Casting

The most cost-effective option, the first choice for high-volume production.

- Lowest cost and short production cycle

- High efficiency and suitable for automated production lines

- Suitable for small to medium-sized cost-sensitive castings

Learn More

Resin Sand Casting

Ideal for high-precision, complex-shaped, high-quality surface castings.

- High dimensional accuracy and good surface finish

- Capable of producing highly complex and thin-walled parts

- Suitable for a wide range of materials, eg, cast steel, alloys.

Learn More

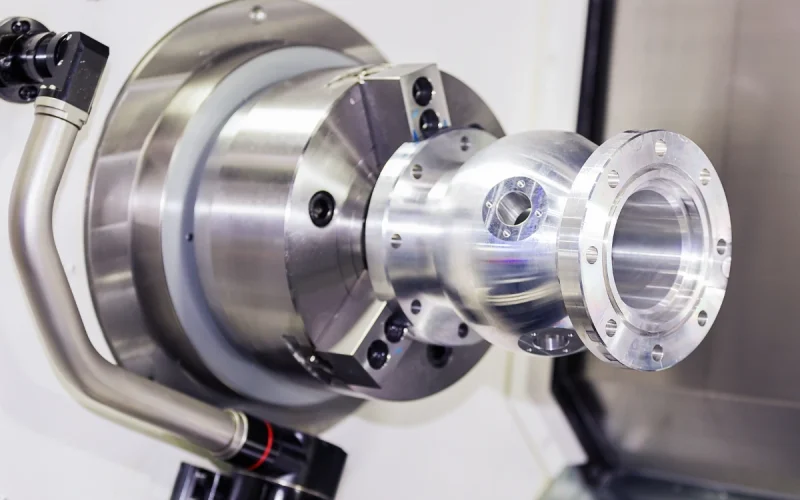

CNC Finishing

The complete solution for precision-machined, assembly-ready cast components.

- Achieve critical tolerances and surface finishes for sealing, bearing, or mating surfaces.

- Eliminate supplier handoffs with single-source casting and machining

Learn More

Materials & Post Processing

Rich material and post processing options, tailor solutions that best suit your projects.

Casting Metals

Casting Iron

Gray cast iron(ASTmA48 Class 35), Ductile cast iron(A536)

Casting Steel

Carbon Steel, Low Alloy Steel, Stainless Steel

Post Processing

Sand Blasting

Remove oxide scale/clay sand layer and improve surface roughness

Bead Blasting

Steel shot peening forms a stress layer, enhancing fatigue strength

Polishing

Machinical polishing and chemical polishing for smooth surface

Heat Treatment

Annealing, quenching + tempering, solution treatment

Coating & Painting

Powder coating or painting for enhanced appeal and corrosion resistance

Need Different Options?

As an expert metal foundry, HDC Manufacturing can provide the best solution in casting process, material configuration, composition analysis, physical property testing, heat treatment technology, etc

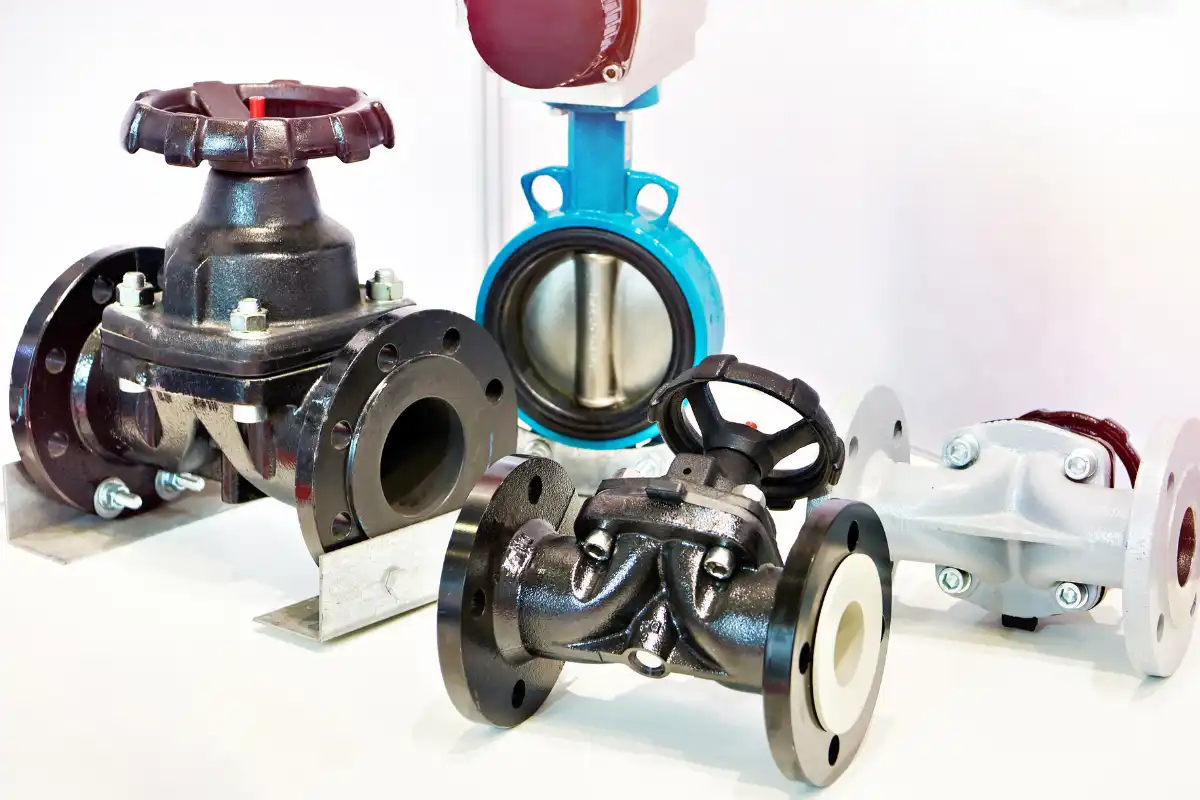

Industries We Serve

Sand casting serves the global industry by its ability to produce large and complex castings

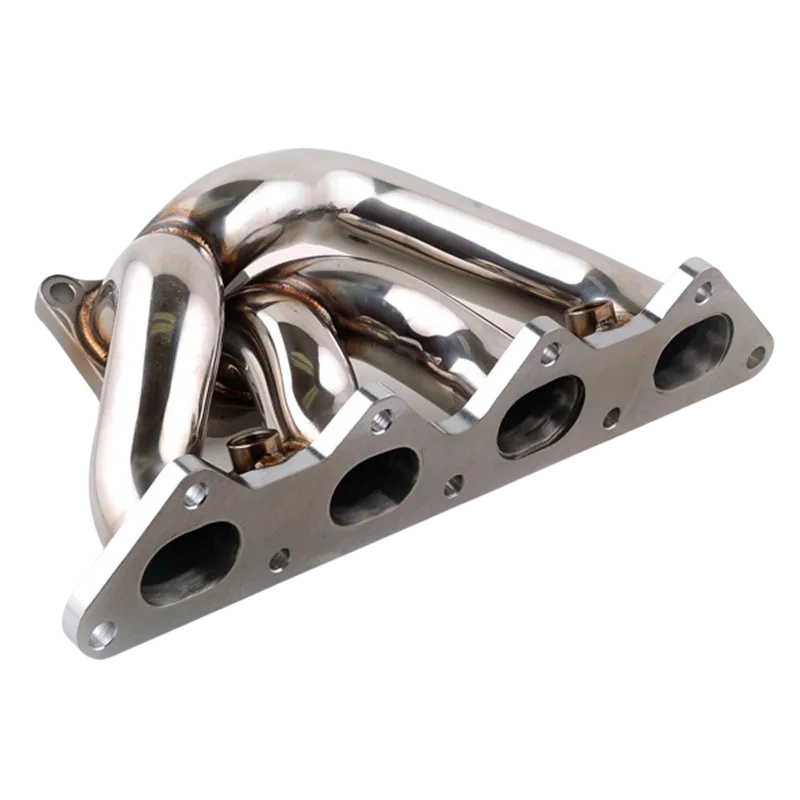

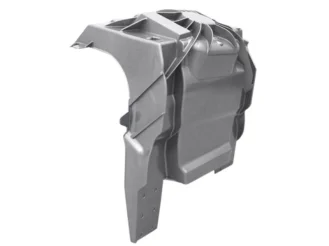

Automotive

Large, complex, and strength-proof parts in engines, transmissions, and chassis

Heavy achinery

Large-size equipment infrastructure parts such as frames and enclosures

Energy Equipment

Housings, impellers, etc., parts that need to withstand high pressure and high temperatures

Aerospace

Non-critical load-bearing structural parts, engine peripheral components, tooling fixtures, etc

Shipbuilding

Marine engine parts, propulsion system components, deck machinery, outfitting parts, etc

Building Hardware

Iron castings that require some strength, wear resistance, or decorative properties

Agricultural Machinery

Large housings, gearboxes, brackets, etc. for tractors, harvesters and other machinery

Rigorous Quality Control for Your Sand Castings

At HDC Manufacturing, we understand that reliable, high-performance castings are critical to your success in demanding markets. Backed by ISO & IATF certifications, we combine strict processes with advanced technology to ensure precision, durability, and reliability for your critical components.

Optical Emission Spectrometer:

Ensures precise alloy chemistry for performance.

Tensile & Hardness Testers:

Validates critical mechanical properties.

Coordinate Measuring Machine (CMM):

Ensures perfect fit and function.

Automated FPI Line:

Reveals hidden defects for integrity.

Why Choose HDC Manufacturing

HDC Manufacturing boosts your business with delicate engineered sand casting service

Certified Excellence, Global Standards

- ISO 9001,14001,45001, IATF 16949 Certified

- Rigorous systems trusted by automotive & industrial leaders worldwide.

Precision Engineered for Critical Applications

- Resin Sand + CNC Finishing Capabilities

- From intricate prototypes to high-volume production with CMM-verified accuracy.

Beyond Inspection: Quality by Process Design

- Spectrometer → FPI Line → Full Traceability

- Proactive control from molten metal to shipment, not just final checks.

Responsive Partner, Not Just a Supplier

- Dedicated Engineering Support

- Your technical challenges solved with DFM feedback and rapid iterations.

Sand Casting Material Selection Guide

Sand casting is a highly adaptable casting process, it is suitable for almost all metals, such as carbon steel, stainless steel, aluminum, copper, and titanium.

When it comes to material selection, here are some main aspects you should consider:

1. Functional Requirements:

- Shock Absorption & Vibration Damping ⇒ Gray Iron

- Wear Resistance + Moderate Strength ⇒ Ductile Iron

- Extreme Load Capacity ⇒ Carbon/Alloy Steel

- Corrosion Resistance ⇒ Stainless Steel

- Lightweight + Heat Dissipation ⇒ Aluminum

2. Working Environment:

- Corrosive Conditions (Seawater/Chemicals): 316 Stainless > Aluminum > Ductile Iron

- High-Temperature (>400°C/750°F): Carbon steel > Ductile iron

- Heavy Wear & Friction: Chrome alloy steel > Ductile iron

- Food/Medical Applications: 316 Stainless Steel

3. Cost Consideration:

- High budget & Performance First:

Stainless steel/alloy steel + resin sand casting & CNC finishing - Balanced Budget:

Ductile iron/aluminum + resin sand for core structures + CNC finishing only on critical areas. - Cost-Sensitive Projects:

Gray iron + green sand casting + limited machining

FAQs

Get answers for key concerns before you request a quote

What sizes and weights of parts can HDC Manufacturing cast?

We can cast parts ranging from 1kg to over 3,000 kg. We handle complex shapes across this size range. If you have different dimensional requirements, please contact us for details.

What materials does HDC Manufacturing cast in?

We primarily cast in various types of iron (gray iron, ductile iron) and steel (carbon steel, low-alloy steel). We also cast some non-ferrous alloys like aluminum bronze. Ask us about your specific material needs.

What is HDC Manufacturing's typical surface finish like?

The standard “as-cast” surface finish is typical for sand casting. We can achieve smoother finishes through secondary processes like machining or polishing if your design requires it.

What tolerances can HDC Manufacturing hold?

Sand casting has standard tolerances based on the part size and material (often following standards like ISO 8062). We achieve tighter tolerances on critical dimensions through careful patternmaking, process control, and CNC finishing.

Does HDC Manufacturing make the patterns?

Yes, we can design and manufacture the patterns (molds) needed for casting your part through drawings or samples. We can also work with patterns you provide if they meet our specifications.

What is HDC Manufacturing's standard lead time for production?

Lead time depends on part complexity, pattern availability, and order size. For standard parts with existing patterns, production can often start within 4-8 weeks. New parts require patternmaking time first. Contact us for a specific quote.

What is the Minimum Order Quantity (MOQ)?

Our MOQ is flexible. We work with both small prototype orders and large production runs. The best price is usually for larger volumes, but we welcome inquiries for any quantity.

Can HDC Manufacturing machine the castings?

We offer machining services as an option. We can supply raw castings (“as-cast”) or provide castings machined to your final drawing specifications.

How does HDC Manufacturing handle shipping, especially internationally?

We have extensive experience shipping castings worldwide, including to Europe, North America, Australia, and New Zealand. We arrange secure packing and reliable freight forwarding. Shipping costs depend on weight, size, and destination.

What are HDC Manufacturing's payment terms?

Standard terms are often T/T, with a deposit required to start production and the balance before shipment. We can discuss terms based on order size and history.

Does HDC Manufacturing have environmental certifications?

Yes, we operate responsibly. We reclaim and reuse sand where possible. We follow environmental regulations and strive to minimize waste. Specific certifications can be discussed upon request.

Get Your Custom Quote Today

Submit your drawings or requirements to get professional process and quick quotes!

Contact Us