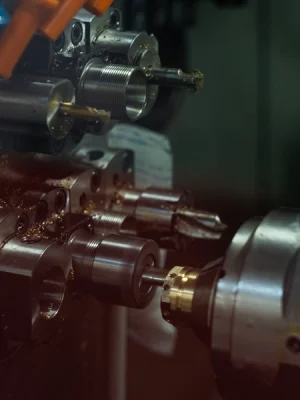

Comprehensive Swiss Screw Machining Services

Dive into the world of Swiss Screw Machining with HDC Manufacturing, where we combine advanced technology with expertise to produce ultra-precise and complex components. Discover how our services can optimize the production of intricate parts for critical applications across diverse industries.

Advantages of Our Swiss Screw Machining Service

Uncover the benefits of Swiss Screw Machining for precision manufacturing, focusing on how HDC’s capabilities meet the high standards of diverse industries.

High Precision

Swiss machining is renowned for achieving extremely tight tolerances, essential for creating intricate parts used in medical devices, aerospace components, and electronic hardware.

Complex Part Production

Capable of producing complex geometries and detailed features in a single operation, reducing the need for secondary processes and ensuring consistency across production batches.

Efficient Material Usage

Swiss machines operate with minimal waste, making them cost-effective, especially when using expensive materials like titanium or specialty alloys.

Scalability

Ideal for both small and large production runs, Swiss screw machining offers flexibility in quantity without compromising the quality or precision of parts.

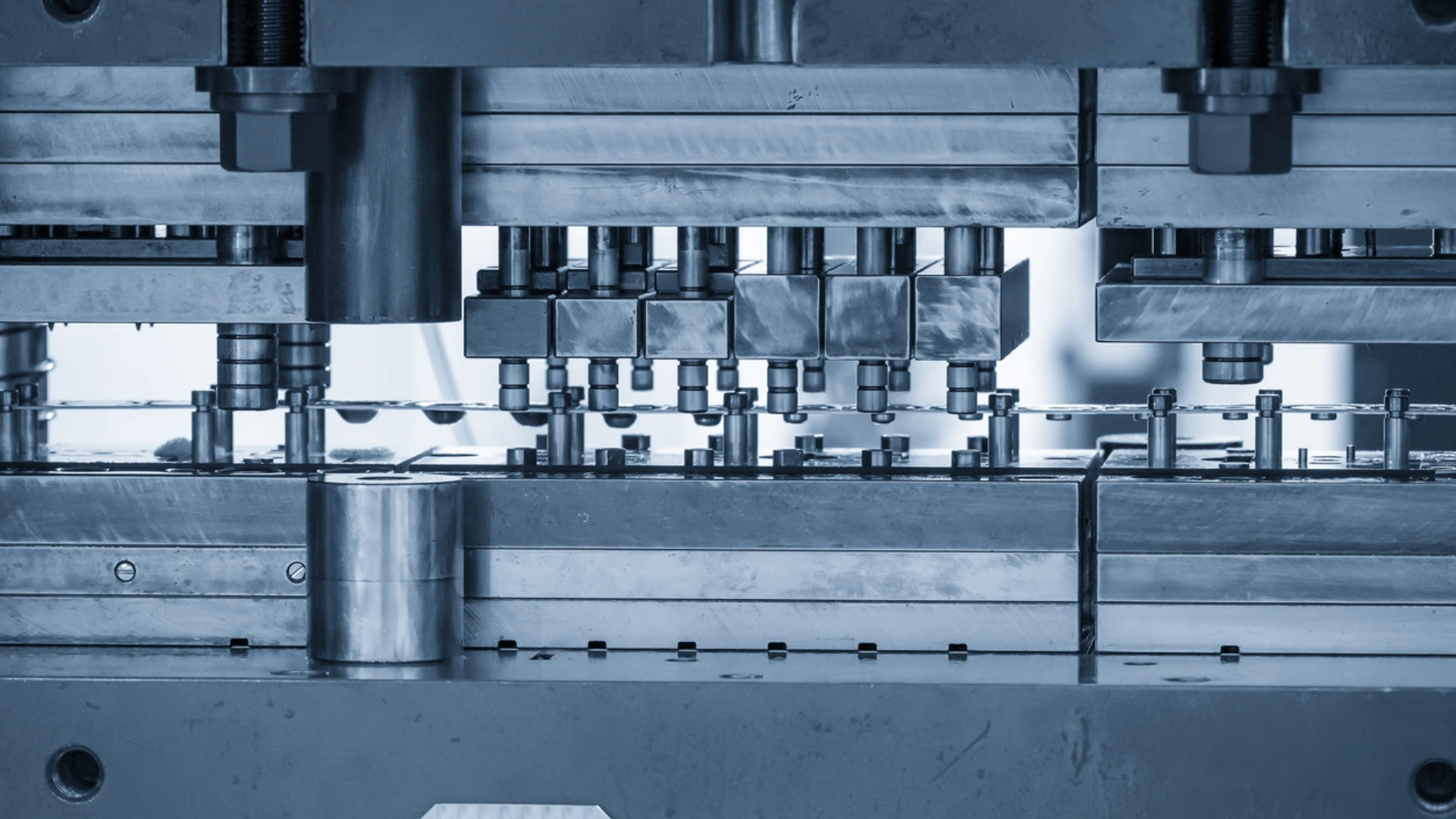

Integrated Operations

Combines multiple operations such as drilling, milling, and turning into one streamlined process, enhancing production speed and reducing overall manufacturing time.

Superior Surface Finish

Delivers excellent surface finishes that often meet or exceed the requirements without additional processing, critical for components that function in visible or high-contact applications.

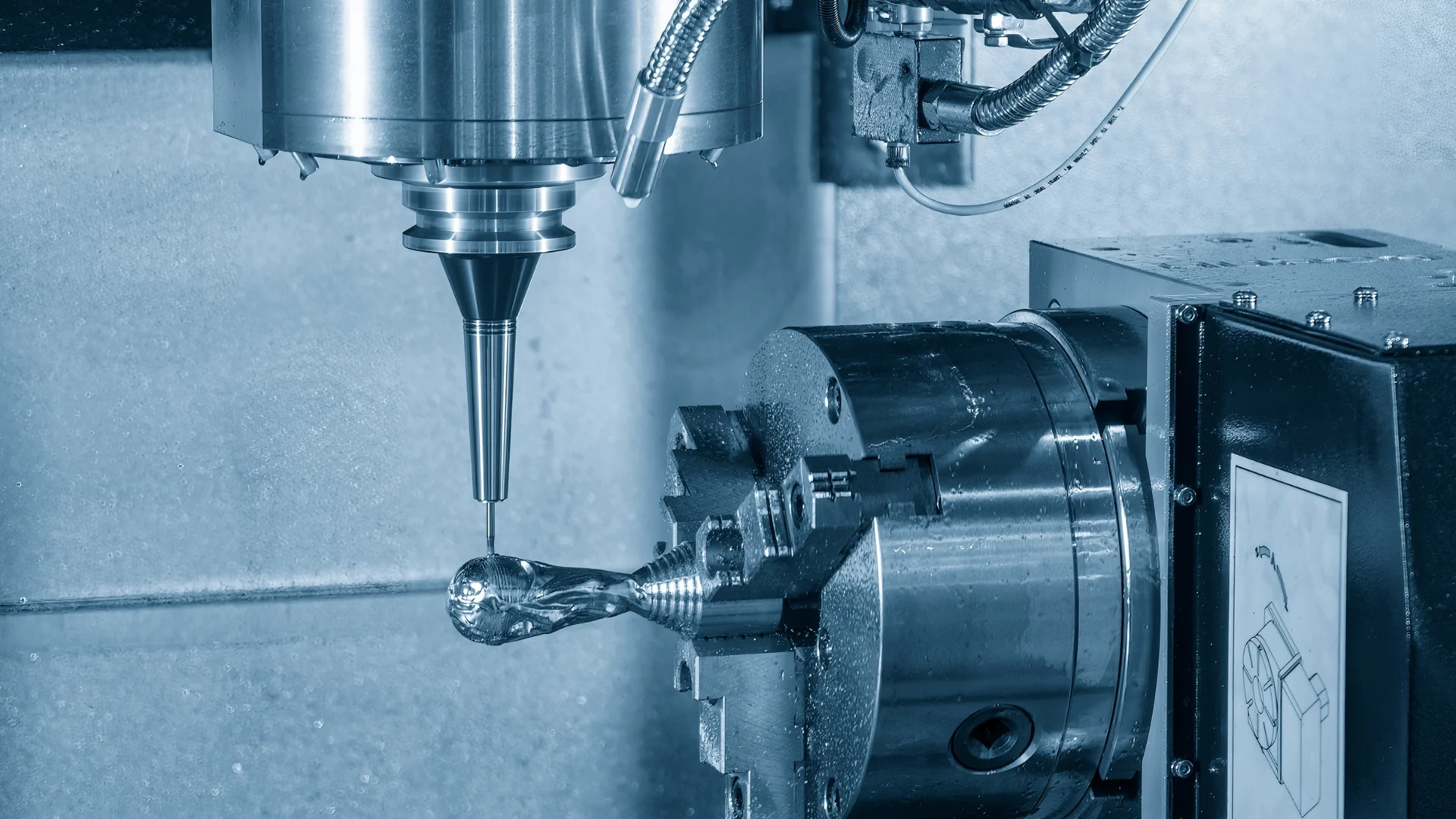

Precision Engineering with Our Swiss Screw Machining

HDC Manufacturing delivers top-tier Swiss screw machining services, distinguished by:

- State-of-the-Art Equipment: Utilizing the latest in Swiss machining technology, HDC Manufacturing ensures high precision and efficiency for all project sizes.

- Experienced Professionals: Our team comprises seasoned experts who specialize in the precise requirements of Swiss screw machining.

- Unmatched Quality Control: HDC Manufacturing adheres to stringent quality standards to ensure each part meets exact specifications.

- Flexible Customization: We offer tailored solutions to accommodate a range of material and design complexities.

- Efficient Production and Support: Quick turnaround times and comprehensive customer support underline our commitment to client satisfaction.

With HDC Manufacturing, benefit from a seamless blend of technology, expertise, and customer-centric services in Swiss screw machining.

Material Options for Swiss Screw Machining

Discover the range of materials we offer for Swiss screw machining, each selected for its unique properties to optimize your precision manufacturing needs.

Stainless Steel

HDC Manufacturing provides grades like 304 and 316, which are known for their excellent corrosion resistance and strength, ideal for creating durable and hygienic components in medical and food processing industries.

Aluminum Alloy

We offer lightweight yet strong alloys such as 6061 and 7075, which are perfect for aerospace and automotive parts that require both strength and weight reduction for enhanced performance.

Carbon Steel

With options like A36 and 1045, HDC utilizes carbon steel for its exceptional toughness and wear resistance, suitable for manufacturing durable parts that withstand rigorous use.

Polymeric Material

HDC Manufacturing provides a range of polymers including PEEK and Nylon, favored for their versatility and lightweight properties, ideal for insulating components in electronic assemblies and consumer goods.

Titanium Alloy

Copper Alloy

Including varieties like C110, HDC Manufacturing offers copper alloys for their outstanding electrical conductivity, commonly used in electrical components and heat exchanges.

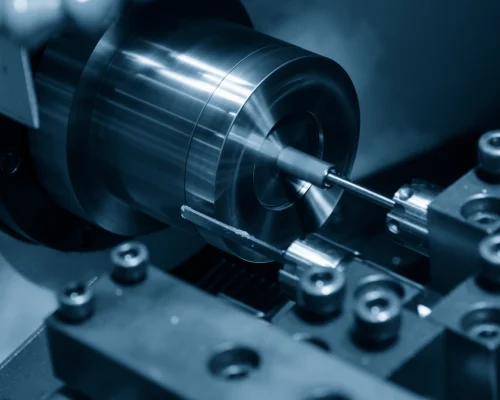

Understanding Swiss Screw Machining

Gain a comprehensive understanding of Swiss screw machining, including its development, unique features, applications, and how it compares to other CNC techniques.

- Development and History: Swiss screw machining, originally developed in Switzerland to create precise watch parts, has evolved significantly over the decades. This method was adapted to accommodate the need for ultra-precision in various miniature components, particularly in the medical and aerospace industries.

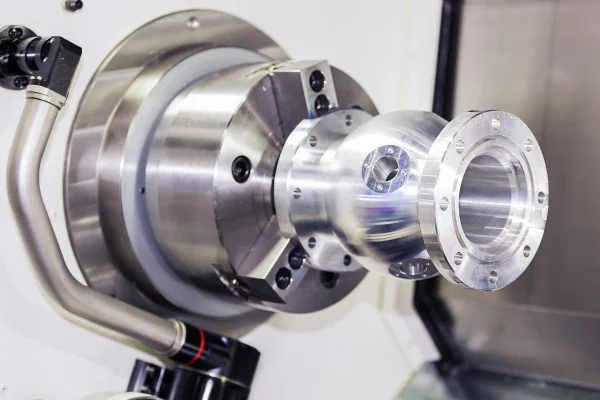

- Key Characteristics: Swiss screw machining is renowned for its ability to produce small, intricate parts with exceptional accuracy. The main feature that distinguishes Swiss machining from conventional CNC machining is the use of a guide bushing. This allows the workpiece to be supported very close to the cutting action, minimizing deflection and vibration, which are critical for maintaining dimensional accuracy in slender, elongated components.

- Comparison to Other CNC Machines: Unlike traditional CNC lathes, Swiss machines operate with a sliding headstock which moves over a stationary workpiece, allowing for less material wastage and higher precision. This method is particularly effective for long and slender turned parts.

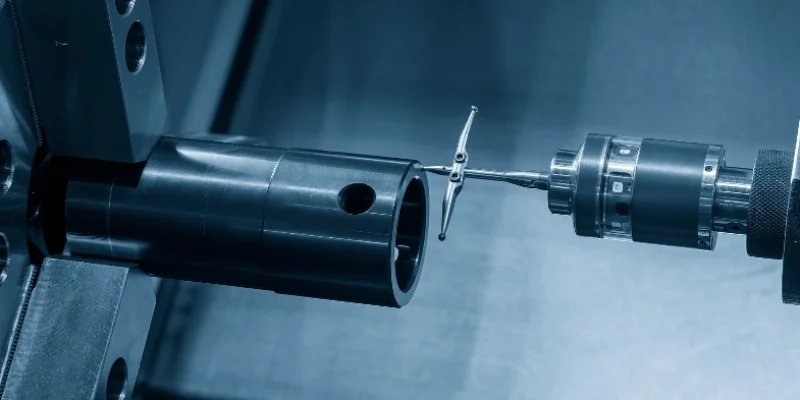

- Suitable Part Types: Swiss machining is ideal for small, complex parts that require precise features like threads, grooves, and slots. Typical parts include medical devices, aerospace fasteners, and electronic connectors.

- Applications: This machining technique is widely used across industries that demand high precision and reliability. Its applications span from medical implants, such as bone screws and dental implants, to critical aerospace components and high-precision automotive sensors.

- Materials Handled: Swiss screw machines can work with a range of materials, including stainless steel, aluminum, brass, copper, titanium, and various polymers and composites, accommodating the specific properties required for different industrial applications.

- Precision Levels: These machines can achieve tolerances as tight as ±0.0001 inches, making them suitable for applications where ultra-high precision is necessary.

- Limitations: The primary drawbacks include the generally higher cost of equipment and operation, as well as the complexity of setup and programming. Additionally, while Swiss machines are excellent for small parts, they are not suitable for large or heavy components.

Key Applications of Swiss Screw Machining

Discover the diverse sectors that benefit from Swiss screw machining, emphasizing the precision and efficiency it brings to each industry.

Automotive Industry

In the automotive sector, Swiss screw machining helps create precision parts such as sensors and bushings, which are essential for the modern, high-performance automotive systems.

Aerospace Industry

Used to manufacture connectors, bushings, and other critical aerospace components that require high strength and must adhere to strict tolerances due to the demanding conditions of aerospace environments.

Medical Industry

Swiss screw machining is crucial for producing intricate components like dental implants, orthopedic screws, and other surgical instruments, where precision is vital for patient safety and device functionality.

Electronics Industry

Swiss machining is perfect for producing small, complex components used in electronic devices, including connectors, pins, and switches, where exact dimensions are crucial for proper assembly and function.

Defense Industry

The defense industry relies on Swiss screw machining for the production of high-precision and reliable components used in military hardware and communications equipment, where failure is not an option.

Precision Standards in Swiss Screw Machining

Explore the exceptional precision capabilities of Swiss screw machining, ensuring unparalleled accuracy for critical components.

| Feature | Typical Tolerance | Precision Details |

|---|---|---|

| General Dimensions | ±0.0005 inches | High precision for general part features and outlines. |

| Critical Tight Tolerances | ±0.0001 inches | Achieved in highly critical, tight-tolerance applications. |

| Surface Finish | As low as 8 micro inches | Superior surface smoothness for high aesthetic and functional quality. |

| Positional Accuracy | ±0.0001 inches | Ensures precise positioning of features relative to each other. |

| Diameter Control | ±0.0001 inches | Exact diameter control for cylindrical parts, is essential for assemblies. |

| Thread Precision | Class 3 Threads | High-precision threading for secure and reliable fastening applications. |

FAQs

What materials can be used for Swiss screw machining at HDC Manufacturing?

We work with a wide variety of materials suitable for Swiss screw machining, including stainless steel, aluminum alloys, brass, titanium, and various polymers, each offering unique benefits for different applications.

What are the typical tolerances achievable with Swiss screw machining?

Swiss screw machining at HDC can achieve tolerances as tight as ±0.0001 inches, making it ideal for producing highly precise components for critical applications.

Can HDC Manufacturing handle high-volume production for Swiss screw machined parts?

Yes, we are equipped to handle large volume orders with the same precision and efficiency as smaller batches, ensuring consistent quality across all parts.

What industries commonly use Swiss screw machined parts from HDC Manufacturing?

Our Swiss screw machined parts are widely used in industries such as medical, aerospace, defense, electronics, and automotive, where precision and reliability are paramount.

How does HDC Manufacturing ensure the quality of Swiss screw machined parts?

We maintain strict quality control throughout the machining process, using advanced measurement and inspection techniques to ensure every part meets stringent industry standards and customer specifications.

What design assistance does HDC Manufacturing provide for Swiss screw machining projects?

Our team of expert engineers is available to assist with part design, material selection, and optimizing manufacturing processes to enhance performance and reduce costs.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact Us

More Solutions

Explore the range of additional services HDC Manufacturing offers, from custom design and prototyping to logistics and post-manufacturing support.