Precision CNC Turning Services & Custom Advice!

At HDC Manufacturing, we provide precision CNC turning services tailored to your unique needs. From custom part machining to expert manufacturing advice, we deliver exceptional quality and reliability for industries worldwide.

Benefits of CNC Turning

Efficiency

Automated processes reduce production time and labor costs.

Precision

Achieve tight tolerances (±0.005mm) and consistent quality.

Versatility

Compatible with metals, plastics, and composites for diverse applications.

Scalability

Suitable for both small prototypes and large production runs.

Customization

Rapid prototyping and design adjustments to meet specific requirements.

Consistency

Uniform results across batches, ensuring product reliability.

Why Choose HDC Manufacturing for CNC Turning?

- Expert Team: Skilled engineers with extensive CNC turning experience.

- Advanced Technology: State-of-the-art CNC machines for complex designs.

- Personalized Service: Tailored solutions to meet your unique requirements.

- Quality Assurance: Rigorous inspection processes for precision and reliability.

- Timely Delivery: On-time completion without compromising quality.

Choose HDC Manufacturing for unparalleled CNC turning services that combine innovation, precision, and customer satisfaction.

Materials for CNC Turning

Explore our CNC turning materials to discover the perfect option for your precision machining needs.

Stainless Steel

- Key Properties: Corrosion resistance, High durability, Excellent strength

- Applications: Automotive components, medical devices, food processing equipment

Aluminum Alloy

- Key Properties: Lightweight, Excellent machinability, High thermal conductivity

- Applications: Aerospace parts, electronic housings, consumer goods

Carbon Steel

- Key Properties: High strength, Affordable, Good wear resistance

- Applications: Industrial machinery, heavy-duty components, tools

Polymeric Material

- Key Properties: Versatile, Durable, Easy to machine

- aApplications: Prototypes, consumer products, electrical insulators

Titanium Alloy

- Key Properties: Exceptional strength-to-weight ratio, Corrosion resistance, Biocompatibility

- Applications: Aerospace components, medical implants, high-performance engineering parts

Copper Alloy

- Key Properties: High electrical conductivity, Excellent thermal conductivity, Corrosion resistance

- Applications: Electrical connectors, heat exchangers, marine components

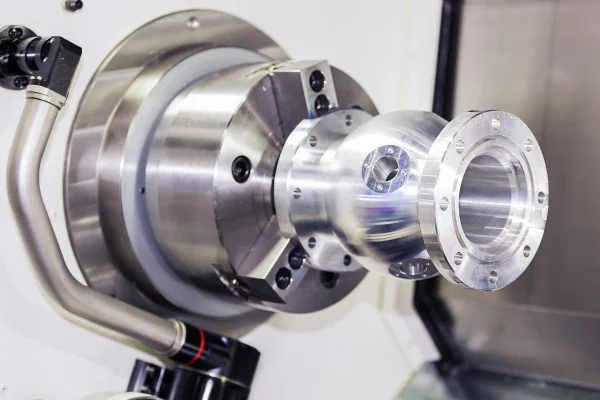

Understanding CNC Turning

Let’s break down the process of CNC turning, learn more about this precision processing method used in manufacturing.

CNC turning is a precision manufacturing process that shapes cylindrical parts by removing material from a rotating workpiece. Key steps include:

- Workpiece Mounting: Secure the material on a high-speed spindle.

- Tool Setup: Install cutting tools on a multi-axis slide mechanism.

- Programming: Input part specifications using CAD/CAM software.

- Cutting Process: Automated tool movement shapes the workpiece.

- Finishing: Perform threading, grooving, or chamfering as needed.

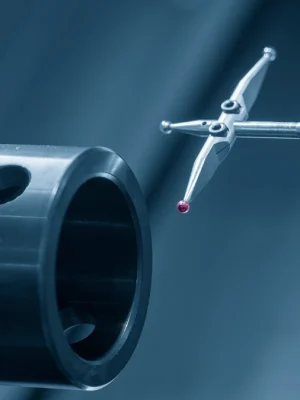

- Inspection: Verify dimensions and quality using CMMs and other tools.

CNC turning is ideal for producing shafts, rods, bushings, and other cylindrical components with high precision and efficiency.

Applications of CNC Turning

CNC turning is commonly used to manufacture aerospace parts, such as landing gear parts, structural fittings, and engine components.

Automotive Industry

CNC turning is essential for manufacturing automotive parts, such as engine components, transmission parts, and suspension systems.

Aerospace Industry

CNC turning is commonly used to manufacture aerospace parts, such as landing gear parts, structural fittings, and engine components.

Medical Industry

It produces critical medical components, including surgical instruments, orthopedic implants, and medical device housings.

Electronics Industry

CNC turning is ideal for creating connectors, sensor components, and housings for electronic devices.

Defense Industry

It is used to produce firearm components, military vehicle parts, and precision defense equipment.

Prototyping

It is a cost-effective solution for rapid prototyping, enabling quick iteration and testing of custom designs.

Tolerances can be achieved by CNC turning

CNC turning, combined with advanced measurement tools like CMMs, ensures tight tolerances:

| Tolerance Type | Typical Range |

|---|---|

| Diameter | +/- 0.005 inches (0.127 mm) |

| Length | +/- 0.010 inches (0.254 mm) |

| Surface Roughness | Ra 32 microinches (0.8 micrometers) |

| Profile | +/- 0.010 inches (0.254 mm) |

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Request Free Quote

More Solutions

Explore the range of additional services HDC Manufacturing offers, from custom design and prototyping to logistics and post-manufacturing support.