Custom CNC Auto Parts With HDC

At HDC, we provide advanced CNC technology to build your custom auto parts. As a professional metal parts manufacturer with 15 years of experience, we focus on precision and quality, trusted by hundreds of customers from all over the world.

One of our major fields is the racing industry, we have been making aftermarket car parts and performance parts for more than ten years.

Low Volume Production

Fast Turnaround

Global Shipping

ISO 9001 Certificate

Advantages of CNC Auto Parts

Intricate Design

You can manufacture auto parts with intricate design through CNC technology, without upfront investment like molds.

Perfect Fit

A customized part is designed for a specific model, so you don’t have to worry about adaptability.

Unmatchable Quality

CNC machining can achieve high precision and surface quality without additional post-processing.

CNC Automotive Engine Parts

Valve Cover

CNC machined from a billet aluminum block, lightweight and durable, helps to seal the valve train, prevents oil leakage, and protects internal components from contamination.

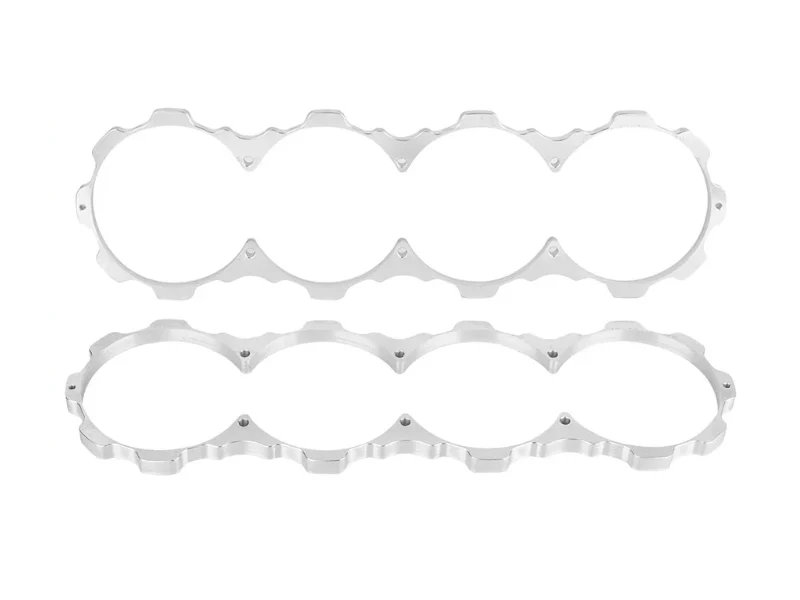

Engine Block Guard

Precision machined aluminum supporter for open deck engine, helps to prevent the cylinder sleeve from deformation during high RPM, also known as sleeve saver.

Magnetic Drain Plug

Built from aluminum with precision threads, a magnet is installed on the end, helping to remove small metal pieces from engine oil and reduce the damage to the oil filter.

Intake Manifold Flange

CNC machined with billet aluminum, it’s a connector of the intake manifold and the engine body. Its core function is to ensure the airtightness of the intake system.

CNC Replacement Car Parts

Titanium Nuts

Made with high-strength titanium alloy, comes in various shapes and sizes. They are suitable for the replacement of broken nuts.

Titanium Bolts

Manufactured using CNC technology, these titanium screws can be customized to any shape and size for high-performance applications or to replace old ones.

Battery Box

CNC Machined with aluminum, this battery box can be customized to fit any model of car, it’s lightweight and can secure the battery tightly during intense driving.

Dipstick

Made of aluminum alloy, this dipstick can be customized with any shape to improve the grap experience and anodized with multiple colors to fit your preference.

Shifter Stop

CNC machined from billet aluminum, with multiple anodized colors. It’s used to limit the range of lateral or longitudinal movement of the shift lever.

Shift Knob

We use CNC to cut aluminum to produce shift knobs that perfectly align with your design. Which will significantly improve the gear shift experience and accuracy.

Front Hood Vent Spacer

Small and simple but effective CNC machined aluminum parts that can help your engine get extra cool air and keep the engine at its best performance.

CNC Car Wheel Parts

Billet Aluminum Wheel

These wheels are CNC machined from a whole piece of aluminum, high strength and lightweight, maybe expensive but definitely worth it.

Wheel Spacer

You can trust HDC for a customized wheel spacer. We make it using CNC machining and the best 6061 & 7075 aluminum. It’s our best-selling auto parts.

Strut Spacer

A struct spacer looks like a wheel spacer, the struct spacer is used to lift up the vehicle. We produce them using the same process and material.

Wheel Lug Nut

At HDC, we tailor wheel lug nuts based on your drawing or sample. You can select aluminum or titanium for high-strength demands.

Why Choose HDC CNC Auto Parts

- Experience: More than 10 years of experience in customizing CNC auto parts.

- Precision: We are able to provide tolerances up to ±0.005mm.

- 50+ Materials: We provide more than 50 materials for your custom products.

- 10+ Finishes: We offer anodizing, plating, powder coating, and so on.

- No MOQ: No minimal order quantity for custom CNC auto parts.

- Large Volume Production: We can handle mass production up to 10000 a month.

- Lower Cost: No MOQ, you can get a discount with large quantities.

- Fast Delivery: Production and delivery completed in as fast as 1 week.

Our Factory

We have a facility of 2500 square meters and are equipped with over 30 CNC machines, which include 20 3-axis CNC machines, 8 4-axis machining centers, and 2 5-axis CNC systems. Besides the machining machine, we also have a CMM machine, hardness and roughness tester for quality control.

Including engineers, designers, machine operators, quality control, and sales teams, we have 50 employees. We are able to take on custom CNC machining orders of all sizes.

How We Produce Wheel Spacer

We produce many different types of aftermarket auto parts, of which, wheel spacer is our most popular product. Below are how these wheel spacers are made.

Wheel Spacer under machining

As we all know, strength is very important for a wheel spacer, so most of our wheel spacer blanks are made of 7075 aluminum by forging. Our aluminum forging parts supplier produces these blanks according to our drawing requirements, we use turning machining to precisely finish the shape to meet dimensional standards, and then employ CNC milling to drill the bolt holes.

One-Stop Custom CNC Auto Parts Solution

Just click the “Get Instant Quote” button, fill the form with your information, clearly describe your needs, and attach drawings or pictures if you have them. You will get our response within 24 hours.

No MOQ for CNC parts, but the price of a single piece of customization will be higher.

We provide discounts for large-volume orders. You can discuss the specific discount ratio with our sales staff in detail during the order process.

We offer a variety of payment methods including T/T, L/C, D/P, and PayPal. If you have other payment needs, please discuss with our sales.

We provide sea, air, and rail shipping, express delivery can choose DHL, UPS, and so on. If there are no special requirements, we will choose the appropriate delivery method according to the agreed delivery date and your address. The shipping cost needs to be borne by the customer.

Yes, we offer FOB service. Our team handles export clearance and vessel booking, while you manage onward shipping. We also provide CIF/DDP options for smoother logistics

Related Products

Turbine Blades

We use 5-axis machining and special alloys to produce these Turbine Blades, which can remain balanced during high-speed rotation and withstand temperatures of several hundred degrees.

Control Arms

Same as the suspension arm, we get forged raw blank control arms from our supplier and then use CNC for final processing. Combine strength and precision in one product.

Chassis Suspension Arm

Forged with aluminum alloy, this suspension arm is extremely strong while remaining lightweight. Our forging parts supplier provides the raw blank, and we use CNC for Fine machining.