CNC Machining Stainless Steel Materials

HDC for Machining Stainless Steel

Stainless steel machining is as popular as steel, as its high strength, superior corrosion resistance, strength -to weight ratio, durability, and low maintenance, which is widely used in different industrial applications, food processing, handling, marine application, and medical devices.

Why Choose Us

High Accuracy

Equipped with an industry-leading 5-axis machine and skilled technician team, we can meet your high precision requirements, not only in prototyping but also in production.

On-Time delivery

We make the delivery as promised schedule, we do as we said, we can the delivery for samples in 20 days and production in 30 days

Quality Assurance

We have an experienced quality control team to ensure all the measures within the tolerance As ISO9001 certificated manufacturer, we have a complete quality system from the material, machine, and surface treatment to packing.

Design Protected

We protect your designs, all your designs are not allowed to show to any third party, and will have a Non-disclosure Agreement with you

Available materials

Stainless steel 304/304L | 1.4301 | X5CrNi18-10

304 is the most commonly used stainless steel, with good machinability, and excellent mechanical properties, which is widely used to make parts that require good corrosion resistance and good performance, also called A2 stainless steel.

Stainless steel 420, martensitic stainless steel, with certain wear resistance and corrosion resistance, high hardness, and other characteristics, are commonly used to machine precision parts, bearings, household appliances, and corrosion-resistant parts, etc.

Stainless steel 416 is a stainless steel with better easy-cutting performance, mainly used in the production of solenoid valves, micro special motors, and electrical components, suitable for automatic lathes and CNC lathes for mass production.

Stainless steel 316/316L | 1.4404 | X2CrNiMo17-12-2

The addition of Mo makes SUS316/316L stainless steel better corrosion resistance than 304, Ideal materials for the medical and marine industry.

Stainless steel 303 | 1.4305 | X8CrNiS18-9

303 stainless steel, an austenitic grade stainless steel, machined for the components requires a high surface finish, such as bolts and nuts.

Stainless steel grade 430, ferritic stainless steel with good corrosion resistance , formability and weldability, widly used in fasteners.

FAQ

Can stainless steel be machined?

Yes, stainless steel is popular machining material, widely used in different industries.

What kinds of stainless steel can be machined?

303, The most common stainless steel materials are 304 and 316. 303 is another frequently used material, due to its perfect machinability, 416,420, and 430 are also used for machining gears, bolts, and other wear-resistant applications.

Why is stainless steel so hard to machine?

Compared with aluminum, stainless steel is a bit hard to machine, due to its good plasticity and high strength, at the same time, the material will be harder during machining and a lot of heat was generated.

Is 304 or 316 easier to machine?

Compared with 316, 304 is easier to machine.

How much does CNC Machining stainless steel parts cost?

It mainly depends on the parts, the material, sizes, and the complexity, If you can send a drawing, we can offer exact costs within one working day.

CNC Machining Stainless Steel Materials FAQS

Steel is considered one of the best and easiest materials to machine – but, what about stainless steel? You’ll find a ton of CNC machining stainless steel materials supplier in various markets around the globe, but we here at HDC Manufacturing consider ourselves as one of the best, if not the best out of all the options!

We are so professionals that we have prepared an FAQ guide just for you! This guide will tell you all about the CNC machining stainless steel materials such as the most common parts and components manufactured, the different processes done, and many more!

Can Stainless Steel Be CNC Machined?

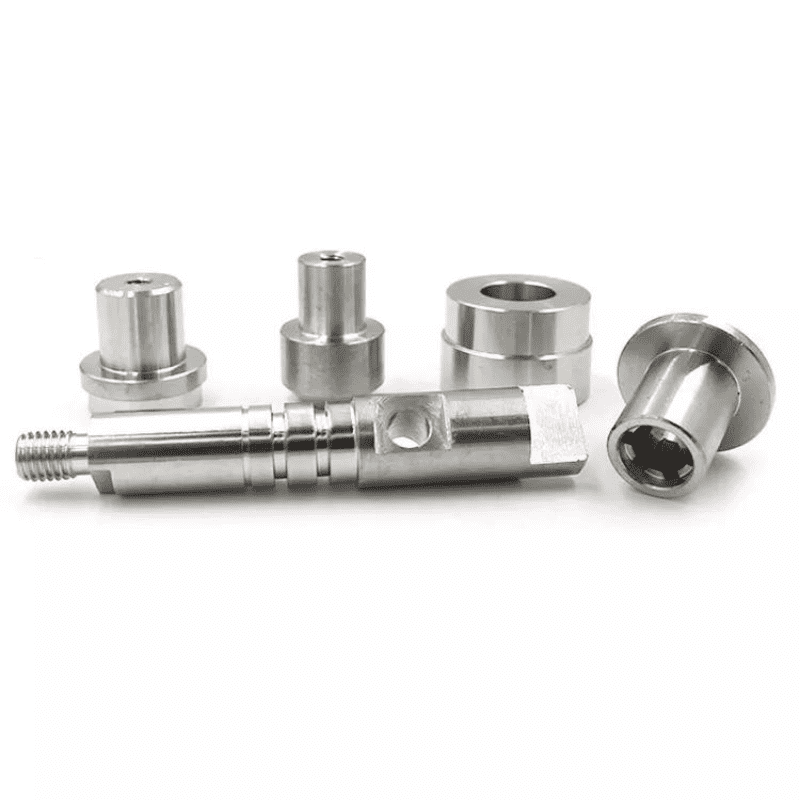

Figure 1 – An image of a CNC machined stainless steel

Yes, stainless steel is a material that is highly machinable, in fact, it is considered one of the best and most used types of metal because of its high versatility, ductility, and resistance. They’re already great when it comes to standard or regular manufacturing – what more if it’s CNC machined?

That brings us to our next question, which is….

What CNC Processes Can You Do to Stainless Steel?

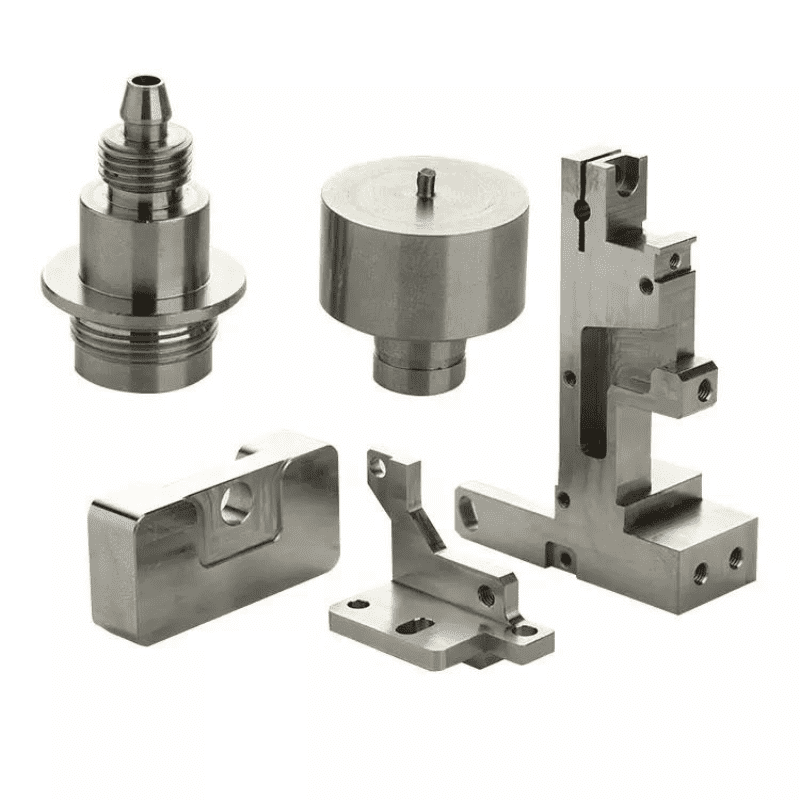

Figure 2 – Image of a stainless steel sheet that has been punched

There’s no discrimination to the CNC procedures and methods you can do with stainless steel. As a matter of fact, the usual manufacturing processes you do with it also apply to CNC machining.

To cite a few of the best and most concrete examples, the CNC processes and methodologies you can do with stainless steel include:

There are quite a few different CNC manufacturing processes that are typically done to CNC stainless steel, and they are:

CNC Turning

Considered as one of the most common CNC machining processes, CNC turning is a process that’s used to make cylindrical parts that are off to extremely high levels of precision. This reduces the overall diameter of the workpiece to a specified measurement and dimension.

CNC Sheet Metal Punching

Punching is a manufacturing procedure that’s done to bore holes and reform/reshape sheet metal or workpiece. Don’t confuse yourself in understanding CNC sheet metal punching because it’s just the same as regular or standard punching – it’s just the way how the processing took place.

CNC Sheet Metal Folding

Last in this list is metal folding. Sheet metal folding is typically a finishing or polishing procedure that is done by bending or folding sheet metal. These folds will be reduced to a few millimetres across the entire plain of workpiece.

These three (3) are the most typical CNC machining processes done to stainless steel workpieces and materials.

NOTE: Just because these are the most common processes and methods done for stainless steel doesn’t mean that your actions and processes are limited to these. There are other CNC manufacturing and machining processes for stainless steel, but these three (3) are just the most common.

What Are the Best Types of Stainless Steel For Your CNC Machining Project?

We here at HDC Manufacturing have about five (5) different types and kinds of stainless steel for our projects – they are:

- SUS303

- SUS304

- SUS316L

- SUS410

- SUS416

Generally, though, these are the best stainless steel types and classifications that are used for CNC machining parts and components. Out of these, SUS303 and SUS304 are the most common because of their high-quality properties and the resistance they have.

What Parts and Components Can You Produce Using CNC Stainless Steel Machining?

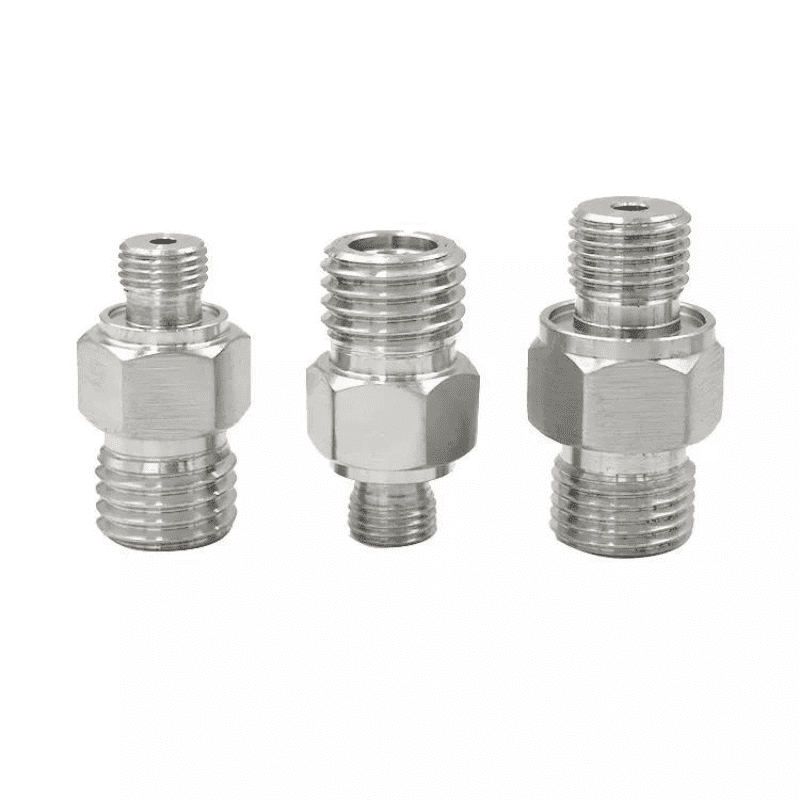

Figure 3 – Stainless steel fasteners

There is a wide variety of products that can be processed by CNC machining stainless steel. These include:

- Gutters

- Nuts & Bolts

- Fasteners

- Kitchen Appliances

- Automotive, Motorcycle, and Aerospace Parts

- Surgical Instruments

- Pressure Vessel

- And Many More!

SUS303 vs. SUS304 Stainless Steels

SUS303 and 304 are two (2) of the most common types of stainless steel types that are used for CNC machining. Here are a few of the differences between these grades:

Durability

SUS304 is a type of austenitic stainless steel that is non-magnetic, which calls for lower electrical and thermal conductivity. It’s also exceptionally tough and corrosion resistant.

Usability

SUS303 is one of the few types of stainless steel that is easy and convenient to use because of its free-cutting capability. On the contrary, SUS303 is considered not weldable and less susceptible to machining. SUS304 is a stainless steel type that is weldable; it’s also the best and ideal stainless steel type for machining. It does not harden with heat treatment – it is not a free-cutting material.

Cost

Last and most definitely not least would be the cost and price of these types. The regular costs change every now and then, so, you can’t be too sure which one is cheaper and more affordable. Generally speaking, SUS304 is cheaper in comparison to its properties against SUS303.

These are the primary differences between SUS303 and SUS304 in stainless steel machining.

NOTE: SUS and SS are the same – SUS is just the Japanese variation (Japanese Industrial Standards or JIS) while SS is the American way of listing it.

Which CNC Machining Stainless Steel Materials Supplier Can You Trust?

Out of the many manufacturers and suppliers you can trust when it comes to CNC machining stainless steels, HDC Manufacturing is the best you can get! You’ll never be able to find another supplier or manufacturer as talented and experienced as us!

For 12+ years, we have produced a vast library of stainless steel materials, parts, and components via CNC machining. We were able to manufacture many different types and kinds of materials and parts using a whole wide range of stainless steel types and kinds!

If you need CNC machining stainless steel automotive, motorcycle, aerospace, industrial, or any other type of industry that heeds stainless steel materials, you can count and bank on us!

Aside from CNC machining stainless steel materials, we here at HDC Manufacturing are also experts and professionals when it comes to CNC rapid prototyping, laser cutting services, metal stamping services, 5-axis CNC machining services, and many more!

Reach out to us and we’ll be more than happy to send a free quotation over!

[toc]