Professional Aerospace Parts Manufacturer

HDC follows the strict aerospace-grade standards to machine parts for the aerospace industry. By utilizing the advanced processing technology, such as 5-axis machining and 3d printing, HDC manufactures aerospace parts that combine precision and quality.

From aluminum, titanium, to heat-resistant nickel alloy, HDC fabricates components with dozens of materials for aircraft, drones, and satellites. With a commitment to quality and fast turnaround, HDC customizes aerospace parts prototypes within a week by CNC machining.

Fast Turnaround

Rapid Prototyping

Cost Effective

High Precision

Types of Aerospace Parts

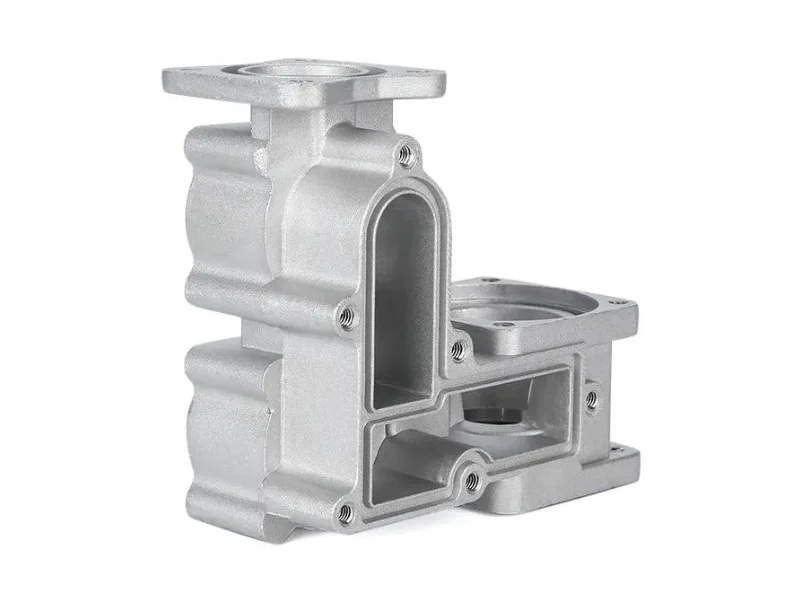

Frame and Housing

HDC uses lightweight materials like aluminum to produce frames and housing for electronic components used in the aerospace industry. Through CNC technology, HDC can easily machine thin wall structures and drill mounting holes with high precision, providing a safe and stable environment for fragile electronic parts.

Connector and Hardware

HDC customizes copper electrical connectors and high-strength titanium alloy bolts and nuts to customers’ specifications, which can significantly improve the stability of connecting cables and enhance durability and safety in critical component interfaces. Both are engineered for high-demand environments.

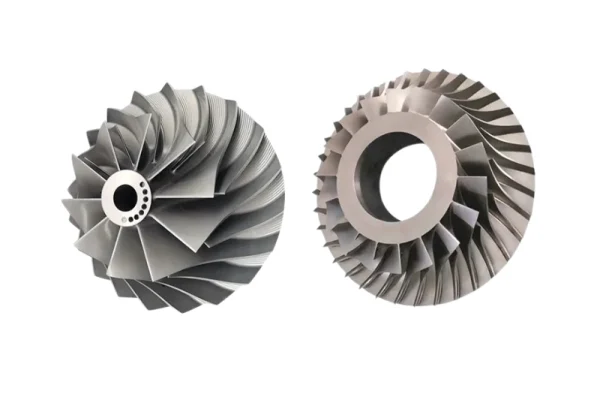

Engine System Components

HDC machining heat-resistant nickel alloy(Inconel, Hastelloy) to produce critical engine components like impellers and compressor blades. We use 5 axis milling to manufacture these complex geometry parts and achieve high precision up to ±0.005mm to ensure the smooth operation of the power system.

Aerospace Parts By Machining Process

HDC integrates multiple machining processes to fabricate parts that can withstand harsh environments in space.

CNC Turning

Suitable for machining products with a cylinder shape, such as connectors and tubes.

CNC Milling

HDC uses lightweight aluminum 7075 to mill cases and housings for drones, aircraft.

5 Axis Machining

With the advanced 5-axis machining center, HDC manufactures the most precise parts.

3D Printing

HDC uses 3D printing to print metal and plastic parts with intricate inner structures.

Forging

We forge aerospace-grade aluminum 7075 to make critical parts that require extreme strength.

Casting

Through investment casting, we mass-produce aerospace parts with complex internal structures.

Laser Cutting

A cost-effective machining process, often used to make panels or cut raw material.

Materials for Aerospace Parts

Material is the base of high-quality aerospace parts. HDC provides certified material for various aerospace applications.

Aluminum Alloy

10+ aluminum alloys available at HDC, including 7075, 6061, 6063, and 5083 etc.

Titanium Alloy

We are experienced in machining high-strength titanium alloy, such as grade 5, grade 7.

Stainless Steel

HDC provides certified stainless steel grades for aerospace parts: 304, 303, 316, etc.

Nickel-Based Alloy

Inconel and Hastelloy are designed for aerospace parts that require strength and heat resistance.

Tailor Aerospace Parts with Diversity

When customizing an aerospace part for your project, HDC is an ideal cooperator to consider. With the numerous customization options we provide, customers can easily purchase parts that perfectly align with their needs.

- Part Size: HDC manufactures parts in a wide range of sizes, from 1000 mm to 1 mm.

- Materials: 50+ materials are available for aerospace parts, including aluminum and titanium.

- Finishes: Anodizing, chrome plating, painting, and powder coating. HDC offers finishes of over 10 types.

- Machining Process: We combine different process methods to manufacture aerospace parts, such as CNC machining, 5-axis machining, forging, and casting.

Features of HDC Aerospace Parts

- Combine Multiple Processes: HDC combines CNC machining with forging or casting, which makes our aerospace parts have precision, strength, and internal details at the same time, perfectly suited for aerospace applications.

- Lightweight: We use lightweight materials and incorporate comprehensive lightweight design, our parts are specially designed for the aerospace sector to efficiently reduce weight.

- Excellent Strength: We use titanium and super alloys to manufacture critical parts, which can satisfy the requirements of high strength and extreme heat resistance in aerospace.

Need parts that meet the aerospace geade standards?

Yes, we offer prototype service. For detailed information, please contact our sales team.

For simple parts, typically within one week. We need to value it according to drawings or samples.

Absolutely, the specific discount is determined according to the quantity.

Yes, all customers are welcome to see our factory, please contact us in advance to get an appointment.

Yes, we offer certification upon request.

Yes, we are a factory certified by IAIF and ISO, with over 3,000 square meters of workshop space and 80 employees.