Custom Mountain Bike Parts

Mountain bikes are not the same with other types of bikes. As a matter of fact, they are typically the most complex because they are equipped with many different parts and components. If you ever feel the need to get custom mountain bike parts that are specific to the model or the unit you’re looking for, don’t hesitate to work with us here at HDC Manufacturing.

Unlike standard bicycles, mountain bikes have more components because of their functionality. Don’t worry, though, because, we here at HDC Manufacturing will help you from start to finish!

HDC’s Custom Mountain Bike Parts

Our mountain bike parts, unlike those made by other manufacturers, have been designed to fit the bicycles of that particular company. When you order custom MTB parts from us, it will be made in accordance to the model – or specific to the unit you’re looking for.

You can use our custom MTB parts to complete your mountain bike from top to bottom. Not only you can improve its overall appearance, but you’ll also be able to ensure that it will function and work appropriately, too.

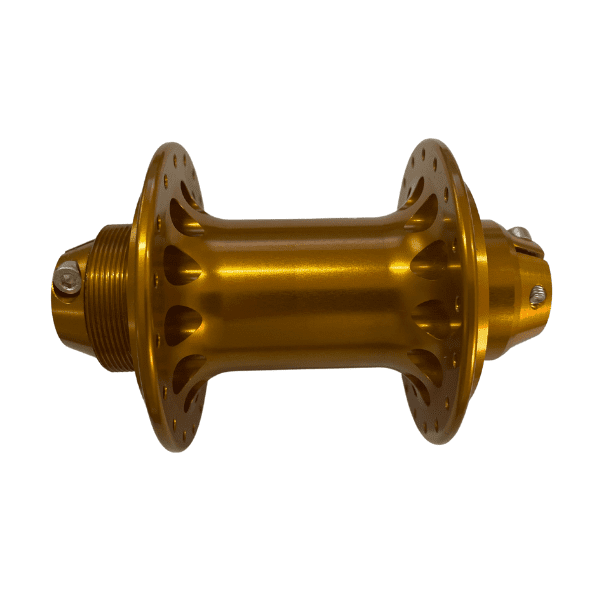

Whether you need bike chainrings, sprockets, pedals, bike stems, to brackets, bolts, and other spare parts, we’ll be more than happy to get you the exact and specific parts and components that you need!

You should never worry about quality, especially when it comes to surface finishing because we are skilled and equipped with various techniques and strategies in finishing. We can perform heat treatment, anodizing, screen printing, powder coating, tumbling, and many more depending on the results and physical attributes you want your custom MTB parts to have.

Our engineers, experts, and quality testing teams will work hand-in-hand to impart the best and highest quality of custom mountain bike parts. We’ll show you why you would never move to a different custom MTB manufacturer when you work with us.

If you’re having trouble finding world-class quality custom mountain bike parts, you will never regret your decision in choosing HDC Manufacturing.

Got questions to ask? We have a customer service team dedicated to serve you 24 hours a day, 7 days a week!

Why Choose HDC?

We would never become the best and top custom mountain bike parts supplier in this part of the country if it weren’t for the expertise, skill, and knowledge of our engineers and experts. For 13+ years, we have accumulated CNC manufacturing and automotive skills and knowledge that many other manufacturers weren’t able to achieve in a span of 2 decades.

HDC Manufacturing specializes in auto parts and components, as well as bike and motorcycle, too.

If you’re looking for quality custom MTB parts that would not burn a hole in your pocket, then, it’s just right that you choose working with us.

Apart from custom mountain bike parts, you can also rely on us if you ever need custom bicycle hubs, bike pedals, crank sets, bike stems, chain rings, pegs, and many more!

Reach out to us and we will be more than happy to help you manufacture custom mountain bike parts accurate to how you want and need them to be!

Mountain Bike Parts That HDC Can Fabricate

HDC can manufacture various mountain bike components that exploit features of advanced materials for heightened performance and longevity. Such elements as lightweight and stiff frames, which are the mainstay of any bike, as well as forks with a good feeling and excellent shocks are the key to a pleasant riding experience. Having a handlebars and seatpost coming from HDC can provide riders with this balance of strength, stiffness and vibration reduction which would give them better control and overall comfort. Wheels rims from HDC will thus reduce rotational inertia, improving on both acceleration and maneuvers. Likewise, HDC can produce cranks and pedals that balance weight and durability for the effective power transmission. The manufacturing of the brake lever, and other components, such as the caliper body, can be enhanced by using HDC resulting into improved braking performance. Also, some derailleur cages and pulleys can be designed to be light and durable and allowing the rider to shift through whatever terrain. The mentioned parts made by HDC are going to play an integral role in creating a mountain bike that has good performance and it can last long.

Materials Used to Make Mountain Bike Parts

Begin a Custom Mountain Bike Parts Project With HDC

Making a custom mountain bike parts project with HDC is very easy to accomplish. You can initiate by going to our website and clicking on the “Get a quote” button. Once you have filled the form, you’ll have to specify all necessary information for mountain bike parts such as dimensions, material, finish, quantity, drawings or blue prints if you have. It’s also useful to known the brand of the mountain bike for which these custom parts are intended. After obtaining your request, our expert sales team will immediately contact you to properly address all your needs, provide design guidance if one is needed, and present you with a quote that would competitively fit your budget. In fact, you can request prototypes before making a final decision to test the quality and precision of the components.

[toc]