- Home

- FAQs

FAQs

Welcome to the HDC Materials Archive, where you can find comprehensive information on all the high-quality materials we offer. Click on each material category to learn more about its properties, applications, and our processing capabilities.

- Home

- FAQs

Quote and Response

Click the "Contact Us" button on our webpage, fill out your information, and describe your needs including quantity, dimensions, materials, finishes, and precision levels. Providing a sketch or detailed design will help us better understand your requirements. You can also directly email us at [sales@hdcmfg.com] or call us at [+86-510-83593929] for immediate assistance. Submit your request to receive your quote inquiry.

Provide as detailed a description of your needs as possible, including precise design drawings or 3D models, which are crucial for an accurate quote. We accept files in multiple formats including CAD, STL, STEP, and DWG.

Minimum order quantities vary significantly depending on the custom parts you require. Plans involving substantial upfront work, such as mold design for injection molding or forging, typically require larger minimum orders, usually in the hundreds. Specific minimum order details will be provided after we assess your custom requirements.

We aim to respond within 24 hours with a detailed and precise quotation. Our response will include all necessary details to proceed with your project.

All fees and taxes will be detailed in the quote.

If your requirements change, please contact us immediately through email or WhatsApp. We require changes to be communicated within 7 days of the original quote to facilitate updates. We will discuss and negotiate the specifics of your updated quote promptly.

The prices in our quotations are guaranteed for 30 days, giving you sufficient time to make decisions. In case of significant market fluctuations or material cost changes, we will communicate and, if necessary, renegotiate the prices to reflect these changes.

Design and Prototyping

Yes, we can assist in refining your design. Our team has extensive experience and can provide professional design suggestions and technical support based on your sketches or detailed drawings, ensuring that the design meets technical requirements while optimizing production efficiency and cost.

Yes, HDC can produce or enhance products based on the samples you provide. Our team is capable of reverse engineering, extracting necessary design and engineering data from your sample, and using this information to reconstruct or optimize the product design. This service is ideal for clients who wish to replicate or improve existing physical products but lack the corresponding technical documents. We also continually refine the design based on testing results and feedback to ensure that the final product better meets your needs.

Yes, clients typically need to cover the costs associated with prototype creation. This includes expenses for materials, design and engineering time, and any specific processing or technical needs. We provide a detailed quote based on the complexity of the project and the materials chosen, well in advance.

Yes, HDC can produce functional prototypes that can be rigorously tested under real-world conditions. We ensure that the prototypes not only visually represent the final product but also functionally simulate the performance of the end product to validate design concepts and performance specifications.

The time required to create a prototype can vary depending on the complexity of the product and the type of materials used. Typically, it takes from a few days to several weeks. We strive to meet our clients' timelines and provide an estimated schedule during the initial consultation.

HDC offers a wide range of materials for prototyping, including plastics, metals, and composites. The choice of material depends on the intended use of the prototype, the desired properties, and the budget. Our team can advise on the best materials based on your specific requirements.

HDC utilizes a variety of design tools and software to support our design and prototyping services. This includes CAD software such as AutoCAD, and SolidWorks, which enable us to create precise models and detailed engineering drawings. We also use CAM software for efficient transition from design to manufacturing.

Manufacturing Capabilities

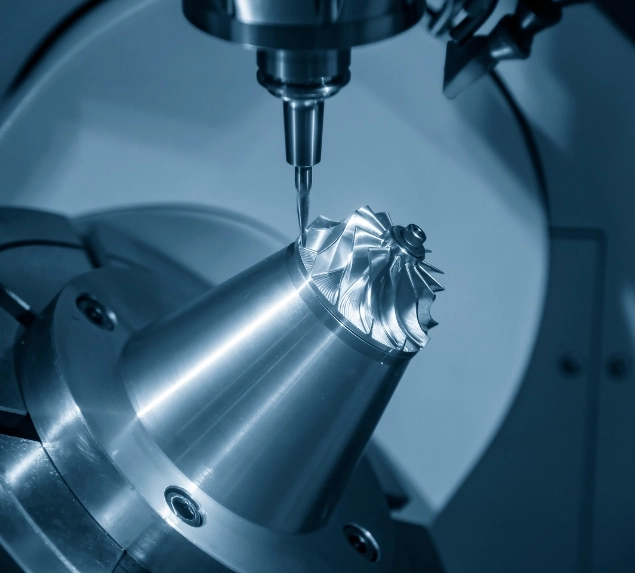

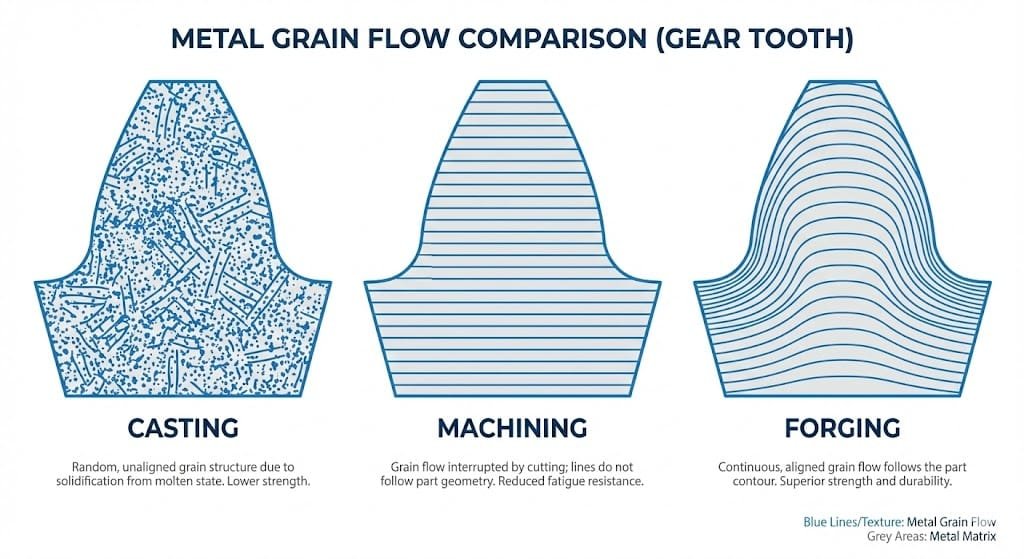

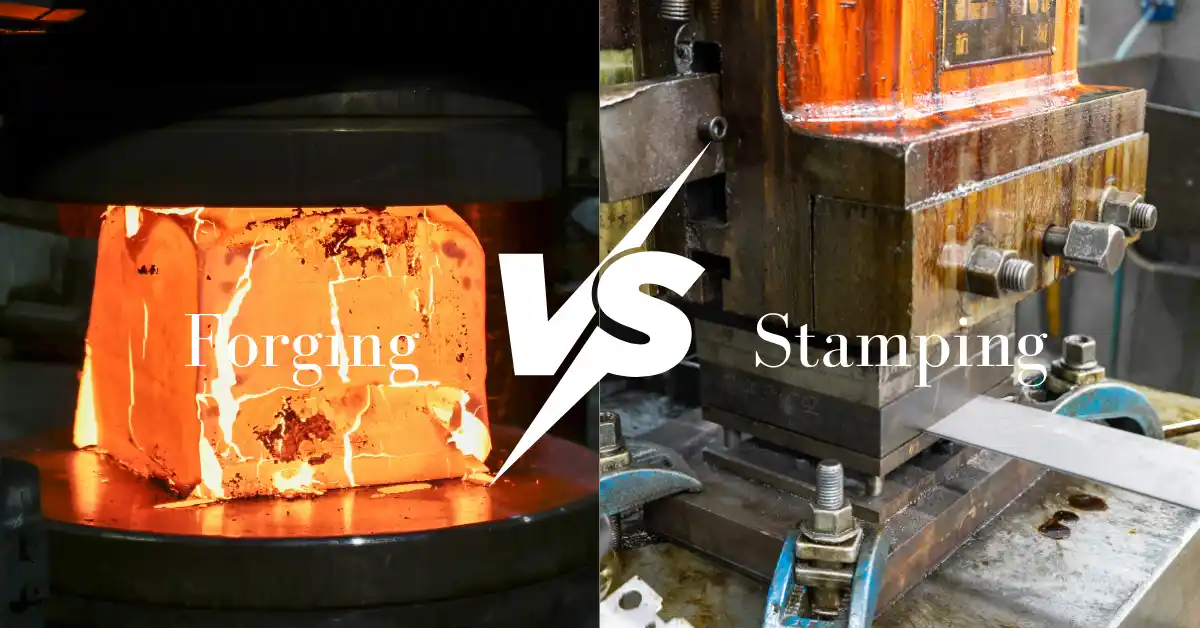

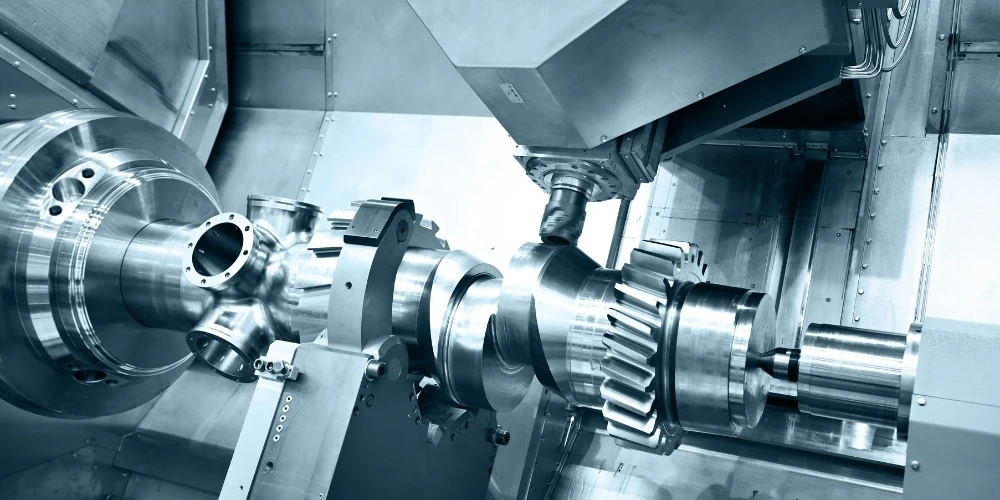

HDC employs a range of advanced manufacturing technologies including CNC machining, injection molding, forging, and more. We continuously integrate the latest technological advancements to maintain high efficiency and precision in our manufacturing processes.

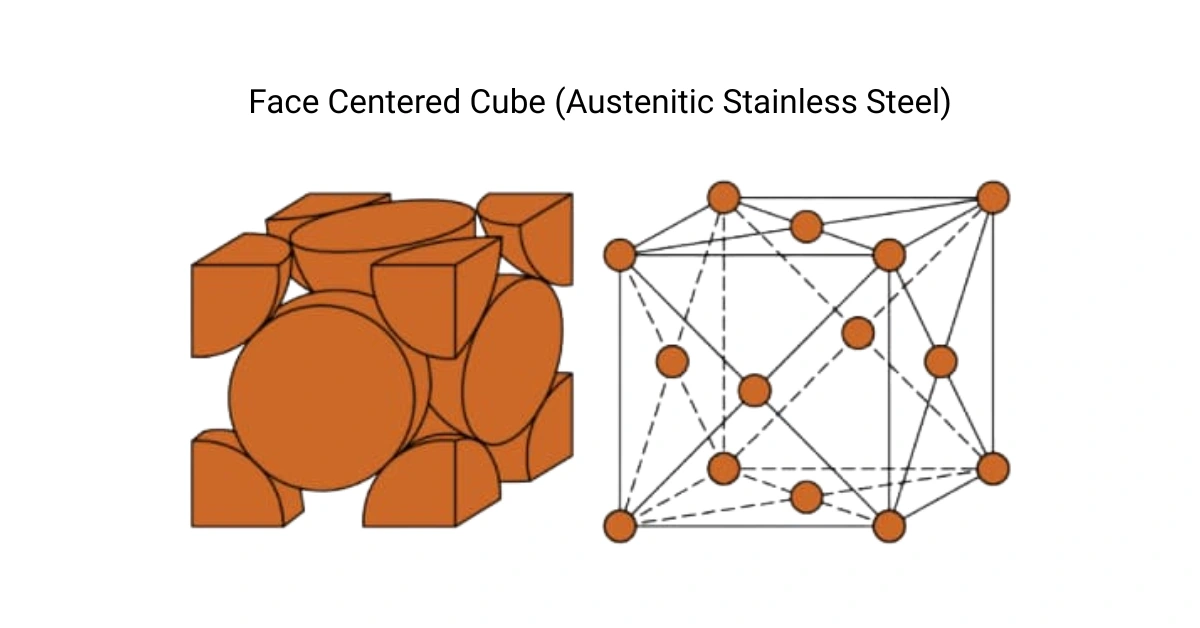

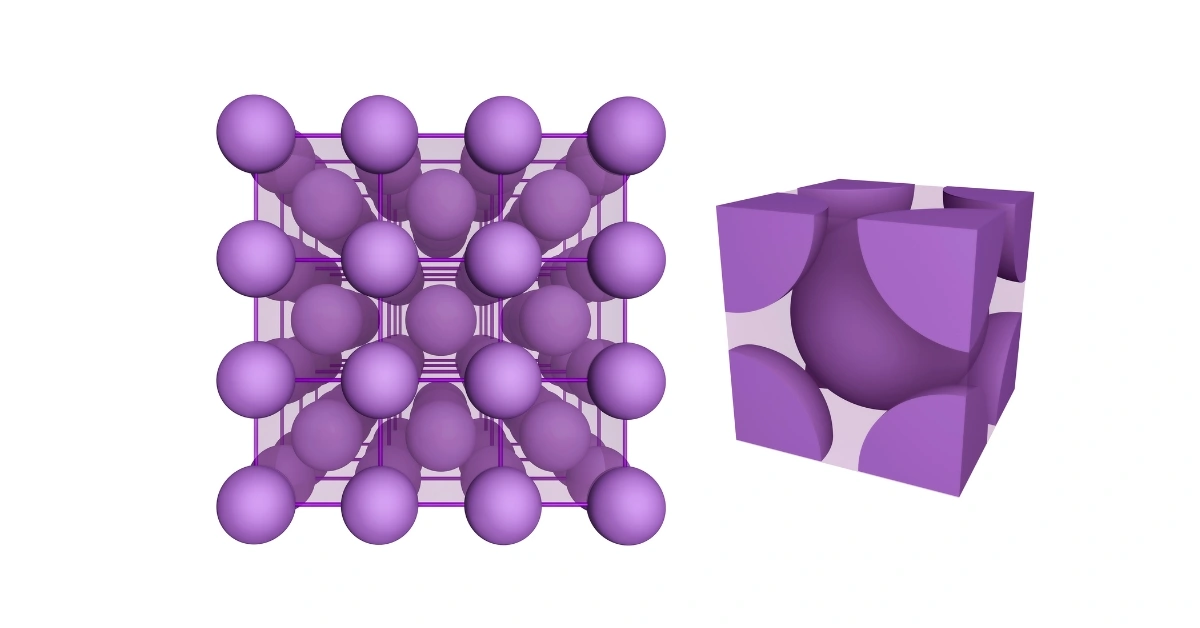

HDC works with a variety of materials, including metals such as aluminum, stainless steel, and titanium, as well as plastics and composite materials. We select materials based on the specific requirements and applications of your project to ensure optimal performance and durability.

Yes, HDC specializes in manufacturing parts with complex geometries. Our advanced machinery and skilled engineers allow us to tackle challenging designs and produce high-precision components.

Absolutely, HDC is well-equipped to handle large-scale production orders. Our facilities are designed for both high-volume manufacturing and maintaining consistent quality across all units.

HDC can achieve tight tolerances typically ranging from ±0.005 inches (±0.127 mm) to ±0.0005 inches (±0.0127 mm), depending on the material and manufacturing process used.

We ensure precision and quality through rigorous quality control procedures, including dimensional inspections, material testing, and performance evaluations, using state-of-the-art measurement and testing equipment.

Yes, HDC offers a variety of finishing processes such as anodizing, plating, painting, and powder coating, which enhance the appearance and corrosion resistance of the parts.

HDC employs comprehensive quality control systems, including ISO 9001 certification and continuous improvement programs, ensuring that all products meet or exceed customer and regulatory requirements.

Production Schedule

The typical lead time for production at HDC varies based on the complexity and volume of the order. Generally, standard orders can be completed within 6 to 8 weeks. However, for more complex or large-scale projects, the lead time might be longer. We strive to provide an accurate timeline during the initial consultation and quote phase.

Yes, HDC is capable of handling urgent or expedited orders. We offer expedited production services for clients who require a faster turnaround. Please notify us at the time of order if you need this service, and we will do our best to accommodate your request. Additional charges may apply for expedited services.

Yes, you can track the progress of your production order through multiple channels. HDC provides regular updates via email, and you can also request updates through WhatsApp for immediate responses. This ensures that you are fully informed about the status of your order at every stage of the production process. Additionally, our customer service team is always ready to assist you with any specific inquiries or provide detailed progress reports upon request.

HDC keeps our clients informed through direct communication channels such as email and phone. In the event of a delay or any change that impacts the delivery date, our project managers will reach out directly to explain the situation, the reasons behind it, and the adjusted timeline.

Quality Assurance

HDC ensures product quality by utilizing professional testing equipment, including Coordinate Measuring Machines (CMMs) and other precision inspection tools. These sophisticated instruments allow us to conduct detailed and accurate measurements of our products, ensuring they meet the exact specifications required. Additionally, our quality assurance process involves multiple stages of inspections throughout the manufacturing process, from the incoming material checks to the final quality control before shipment. This comprehensive approach guarantees that every product we deliver is of the highest quality.

Yes, all materials used by HDC are certified and sourced from reputable suppliers. We ensure that each material batch complies with industry specifications and our own high standards for quality.

Yes, HDC complies with international quality standards such as ISO 9001. We are committed to maintaining high standards in our manufacturing processes, which enables us to serve global markets effectively.

If a product defect is identified, HDC takes full responsibility by re-manufacturing the defective product at no additional cost to the client and covering all associated shipping expenses. We also conduct a root cause analysis to prevent future occurrences and maintain our commitment to quality.

Shipping and Payment

HDC offers a variety of shipping options to meet different needs, including standard ground shipping, expedited air freight, and sea transportation for larger shipments. We work with major carriers to provide reliable and efficient delivery services.

Shipping costs are calculated based on the weight and volume of the shipment, the type of shipping service selected, and the destination. We strive to offer competitive rates and will provide a detailed breakdown of shipping costs in the quote.

HDC accepts multiple payment methods including bank transfers, credit cards, and electronic payments through platforms like PayPal. We aim to accommodate various preferences to ensure a smooth transaction process.

Yes, we typically require a deposit to begin production. The deposit amount can vary depending on the project's scope and total cost but usually represents a percentage of the total order value.

Full payment is due upon completion of production and prior to shipment. We provide detailed invoices and payment instructions to ensure clarity and convenience for our clients.

For international shipments, HDC typically ships under the terms of Free On Board (FOB). This means that customers are responsible for shipping costs, insurance, and any customs or import duties from the point the goods are loaded onto the shipping vessel. We assist by providing all necessary documentation for customs clearance.

Compliance and Certifications

HDC is certified under ISO 9001, which is a recognized international standard for quality management systems. This certification ensures that we consistently provide products and services that meet customer and regulatory requirements while striving to enhance customer satisfaction through effective application of our system, including processes for continual improvement and assurance of conformity to customer and applicable statutory and regulatory requirements.

Yes, HDC’s products comply with various international standards, including those set by ASTM International, SAE International, and the International Organization for Standardization (ISO). We ensure our products meet specific standards relevant to different industries, such as aerospace, automotive, and medical devices.

Absolutely. HDC can provide clients with all necessary certification documentation to verify compliance with the required standards and regulations. These documents are available upon request and can be supplied as part of the quality assurance and product delivery process.

HDC is committed to protecting the privacy and security of our clients' data. We implement robust data protection policies and employ advanced security measures to safeguard all personal and proprietary information. Our strategies include the use of encrypted data storage, secure communication channels, and restricted access controls that limit data access to authorized personnel only. Regular security training for employees and periodic audits of our data protection practices help ensure ongoing compliance with international data privacy standards.

Request a Instant Quote!