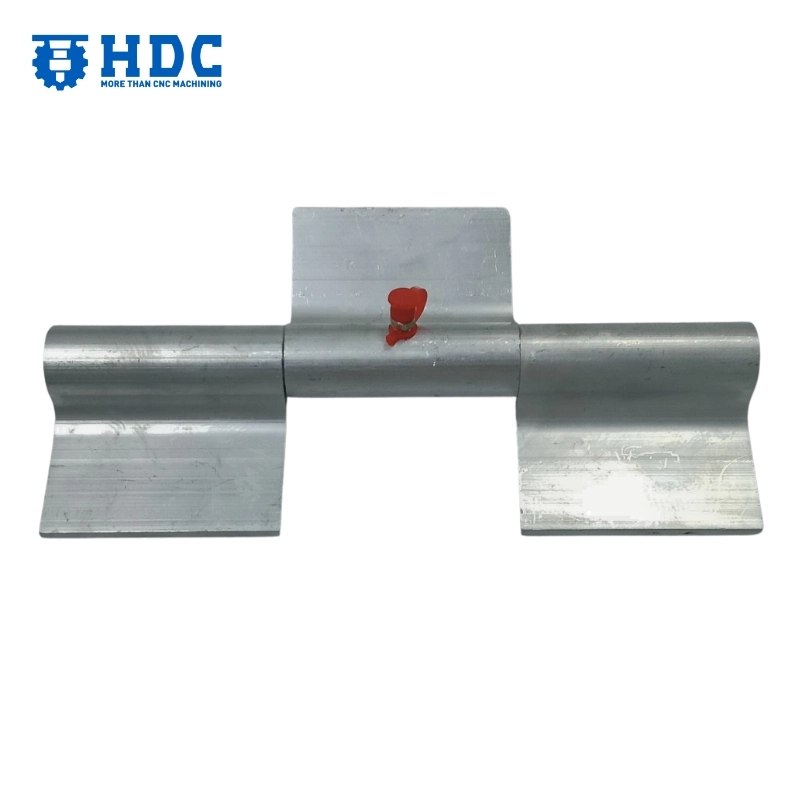

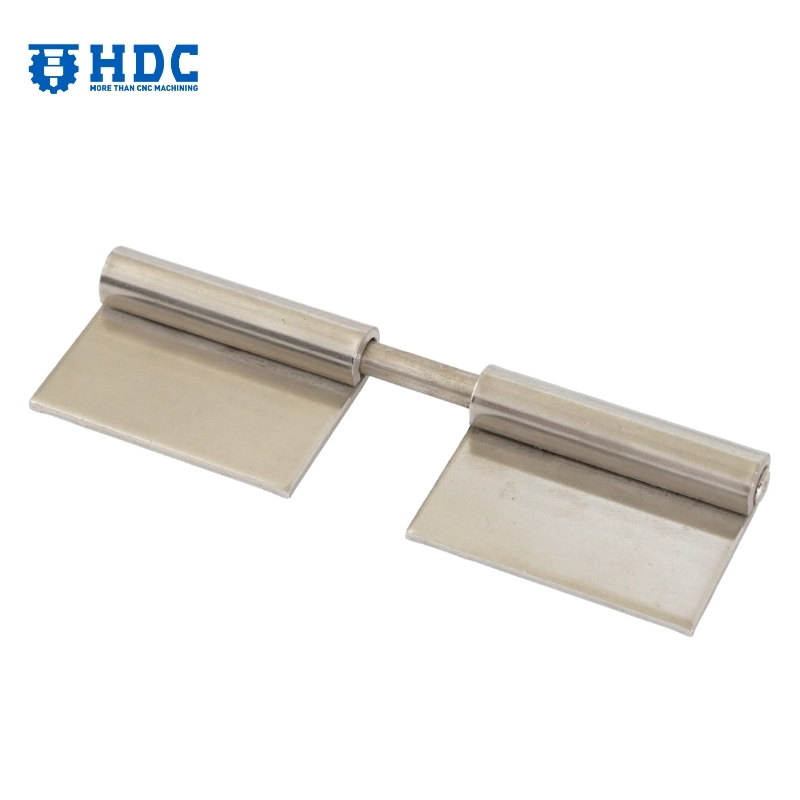

Gate Barrel Hinges

Gate barrel hinges are a standard type of hinge used in metal gate systems that are a lift-off pivot hinge with a round barrel. They can also be referred to as weld on barrel hinges and heavy-duty gate barrel hinges which are a great choice for gates and doors such as trailer gates. Also, gate barrel hinges can meet tight tolerance which are your optimum use for gates with panic hardware, electric locks or strikes, and countless projects where a durable pivot joint is required.

When it comes to offering the best quality while also performing the best customer assistance, HDC is probably the top gun of the bunch. At HDC, we offer highly durable gate barrel hinges in a wide range of applications. HDC’s weld on barrel hinges provide a strong, firm and effortless procedure for attaching heavy-duty gate frames and are used in liftgate or non-removable door implementations. The components we manufacture here provide the perfect showcase in multiple industries. Today, HDC’s gate barrel hinges are the hottest selling and versatile door hinges on the market.

Barrel Hinges Specifications

HDC gate barrel hinges have various materials like steel and stainless steel with several grades for any application. The length choice can be 4″/5″/6″7″. They are all perfect for right or left-handed gates. All the said materials are available with non-compulsory grease fitting. We all know that a part’s performance will prolong if it has a good surface treatment. So, HDC offers a lot of surface treatments for you to choose from, which can be powder coating, zinc plating, passivating and so much more that have a durable rusting-resistant design that guarantees its longevity and durability. Regardless of your preferred surface treatment, our experienced technicians are always ready to guide you with it.

| Gate Barrel Hinge | |||||

| Barrel Hinge Size | Length | Width | Depth | Weld Plate | Pin Size |

| 4″ | 4-3/4″ | 2-1/8″ | 1″ | 3/8″ | 1/2″ |

| 5″ | 5-3/4″ | 1-9/16″ | 15/16″ | 3/16″ | 5/8″ |

| 6″ | 7-1/4″ | 1-3/4″ | 1-1/2″ | 3/16″ | 3/4″ |

| 7″ | 7-1/4″ | 1-9/16″ | 1-1/4″ | 3/16″ | 3/4″ |

Related Weld On Hinges HDC Produce

We manufacture steel weld-on hinges depending on your desired features, they can also be painted and customized for your project. Different kinds of finishes may also be applied for the additional more aesthetic and heavy-duty components. we have experienced technican team to offer engineering consulting for each client.

Steel weld on hinges

Stainless steel weld on hinges

Aluminum weld on hinges

HDC Custom-made Gate Barrel Hinges Service

We accept custom-made gate barrel hinges according to your preferences. You may request to have your desired color and size depending on your project’ s needs.

Gate barrel hinge has a great aesthetic design different from the customary design. You can choose a long list of sizes with or without grease fittings.

Moreover, hinges with or without welded plates are both appropriate option based on your requirements. We are also pleased to send free samples.

Our team has very specialized product knowledge and experience in helping our customers solve problems, and we can be trusted to maintain a high level of customer satisfaction in over thirteen years of service.

Why HDC Gate Barrel Hinges?

As an ISO9001-certified manufacturer of weld-on barrel hinges components, HDC assures that you can get the most out of your part. Our experts have trained and learned everything to sustain the customers’ high level of the satisfactory rate for more than thirteen years of service. HDC also makes weld-on barrel hinges endure every weather and harsh environment.

The weld-on barrel hinge services of HDC will surely make your heavy steel gates, doors, etc., firmly attached to its frame for as long as you want it. Its coating gives the best protection against rust and erosion. Fast and effortless installation using our best weld-on barrel hinges components are what you are getting in HDC.

For many years, HDC managed to get on top and continues to acquire the best machinery and facilities designed for manufacturing trailer parts. HDC’s engineers, technicians, and workers built good connections and cooperation to deliver a flawless component for the customers and clients.

Yes, we are offering weld-on barrel hinges, but you don’ t know yet that almost all types of weld-on hinges (butt hinges, strap hinges, ball-bearing hinges, bullet hinges, etc.) are obtainable in HDC.

HDC believes in the power of intricacy and hard work to ensure one’s quality. All of the components undergo a strict inspection before shipping them out to keep the level of quality and quality consistency.

An ISO 9001-certified company is here to support your needs! Contact us now and receive the finest assistance you will ever experience.

FAQs About Gate Barrel Hinges

In the realm of architectural articulation, a cylindrical hinge, also denoted as a barrel bolt hinge or barrel hinge pin, emerges as a hinge variant frequently deployed in portal structures and entrances. Comprising two interconnected cylindrical elements or 'barrels,' this hinge executes rotational movements around a central axis. One of the barrels affixes to the portal or entrance frame, while its counterpart secures itself to the portal or entrance proper. The barrels coalesce through a pin traversing their core, facilitating rotational maneuverability.

The deployment of barrel hinges is prevalent in robust scenarios where endurance and potency reign supreme. Renowned for their adeptness in supporting weighty portals and entrances, barrel hinges execute a seamless oscillation. The structural blueprint of barrel hinges effectively disperses gravitational forces uniformly, thereby mitigating undue strain on the hinge constituents.

In the realm of architectural articulation, whether denoted as a barrel bolt hinge or barrel hinge pin, a singular hinge emanates with distinct intricacies in its structural composition and operational dynamics. Encompassing dual interconnected cylindrical entities, it orchestrates rotational maneuvers around a pivotal axis.

Esteemed in applications demanding sturdiness, this hinge epitomizes endurance, proficiently shouldering the burden of substantial doors and gates. Renowned for its harmonious oscillation, the barrel hinge not only assures fluid motion but also meticulously balances the gravitational load, mitigating strain on individual constituents. In synopsis, the barrel hinge stands as a resilient and adaptable resolution, encapsulating an unparalleled amalgamation of structural robustness and streamlined functionality within architectural and portal-related contexts.

The barrel hinge establishes its distinctiveness through a singular cylindrical configuration, facilitating efficacious rotational maneuvers and augmenting adaptability in architectural contexts. Noteworthy is its robust resilience, surpassing alternative hinges by adeptly sustaining weighty doors and gates over extended durations. The hinge's defining feature lies in its seamless operational finesse, orchestrating a continuous oscillation for an enriched user encounter. Moreover, it excels in equitably disseminating gravitational forces, diminishing strain on constituent parts and ensuring protracted endurance. Its versatile nature positions it as a multifaceted resolution, amalgamating structural soundness and operational efficiency across a myriad of applications.

- Cylindrical Elements: Interconnected barrels, integral to the hinge's core, facilitating rotational movements around a central axis.

- Pivot Mechanism: The central mechanism governing the hinge's operation. One barrel attaches to the door or gate frame, while its counterpart secures itself to the door or gate, enabling seamless rotational mobility.

- Central Pin: The pivotal pin traversing the core of cylindrical elements. A fundamental enabler, propelling the rotational dynamics of the hinge.

This elucidation reveals the nuanced functionality of the barrel hinge, whether contemplated within the framework of a barrel bolt hinge or barrel hinge pin. These constituent elements synergize to bestow structural robustness and operational efficacy upon the hinge.

This elucidation reveals the nuanced functionality of the barrel hinge, whether contemplated within the framework of a barrel bolt hinge or barrel hinge pin. These constituent elements synergize to bestow structural robustness and operational efficacy upon the hinge.- Forged Steel: Meticulously selected for its tenacious robustness and enduring durability, an exemplary choice for the rigors of heavy-duty applications.

- Stainless Steel: Basking in its illustrious reputation for defying corrosion, this metallurgical marvel guarantees prolonged existence with minimal maintenance demands.

- Brass: A harmonious amalgamation of visual allure and utilitarian finesse, esteeming its prowess in corrosion defiance and intrinsic elegance.

- Bronze: Exhibiting a formidable resilience against the capricious whims of weather, it imparts an ageless, enduring quality to the hinge.

- Aluminum: Seamlessly marrying featherlight attributes with unyielding strength, this material is venerated for its corrosion resistance and the facile nature of its machinability.

This concise exposé delves into the multifaceted realm of materials instrumental in the meticulous craftsmanship of barrel hinges, empowering discerning decisions tailored to the specifics of varied application needs.

This concise exposé delves into the multifaceted realm of materials instrumental in the meticulous craftsmanship of barrel hinges, empowering discerning decisions tailored to the specifics of varied application needs.- Polished Chrome: Radiating a luminous brilliance, the polished chrome finishing introduces a contemporary touch while repelling tarnish, ensuring an enduring visual allure.

- Satin Nickel: Epitomizing subdued elegance, the satin nickel finish seamlessly marries sophistication with resistance to scratches and corrosion.

- Antique Brass: Endowing a timeless, antique allure, this finishing option seamlessly intertwines vintage aesthetics with laudable resistance against corrosion.

- Oil-Rubbed Bronze: Disclosing a sumptuous, dark patina, the oil-rubbed bronze finish imparts an antiquated charm, providing both durability and protection against the elements.

- Powder Coating: Bestowed in a kaleidoscope of hues, powder coating delivers not only aesthetic vibrancy but also an additional defensive layer, rendering it resilient against corrosion and wear.

Empowering individuals to tailor the aesthetic allure and functional attributes of barrel hinges, the selection from these finishing options promises a bespoke touch to match specific preferences and application requisites.

Empowering individuals to tailor the aesthetic allure and functional attributes of barrel hinges, the selection from these finishing options promises a bespoke touch to match specific preferences and application requisites.Barrel hinges, distinguished by their sturdy and multifaceted construction, are extensively employed in a myriad of applications. From providing seamless support to heavy doors and gates to elevating the functionality of cabinetry and furniture, these hinges showcase a remarkable level of versatility. Sectors such as automotive, heavy machinery, and marine industries enthusiastically adopt barrel hinges for their exceptional structural resilience and consistent performance. Their utility extends to architectural frameworks, not only enhancing functionality but also adding an aesthetic flair. In essence, barrel hinges stand as reliable components, ensuring enduring durability and fluid operation across a diverse spectrum of scenarios.

Ensuring the enduring lifespan and peak operational efficacy of barrel hinges necessitates pivotal maintenance protocols. Periodic cleansing employing a gentle detergent, meticulous lubrication of pivotal junctures, and systematic scrutiny for signs of wear emerge as indispensable procedures. The act of diligently tightening any slackened screws, employing strategies to prevent corrosion, and fine-tuning the hinges for precise alignment collectively contribute to the perpetuation of their optimal functionality. Abiding by these succinct directives will proficiently preserve barrel hinges, fostering resilience across a spectrum of diverse applications.

To tailor barrel hinges to specific needs, commence by precisely defining requirements encompassing size, weight, and material preferences.

Make judicious material selections, opting for steel, stainless steel, or brass, contingent on your unique demands. Accuracy in specifying dimensions is paramount, ensuring optimal performance.

Delve into diverse finish options such as polished chrome, antique brass, or personalized powder coating. Clearly communicate load capacity requirements to the manufacturer, elucidating the expected weight the hinges must adeptly support.

Elaborate on additional features desired, be it self-closing mechanisms or adjustable tension. Prior to placing a comprehensive order, judiciously scrutinize samples or prototypes to evaluate design and functionality.

Inquire about rigorous testing methodologies, encompassing facets like load testing and corrosion resistance. Engage in a detailed discussion on production timelines and budget constraints to foster a seamless collaboration.

Finally, meticulously review and comprehend the manufacturer's terms and warranty policies to ensure a harmonious partnership.

Why choose HDC?

HDC is a renowned provider of gate barrel hinges that specialize in providing high-grade, durable products designed to meet the highest standards of quality. Utilizing advanced manufacturing processes and materials, we ensure our gate barrel hinges provide superior strength and robustness for lasting use. With our wide range of sizes and styles, you can be sure to find a hinge that fits your needs. Whether you’re looking for decorative or functional purposes, our experts will help you choose the best solution. We are committed to delivering excellent customer service and only the highest-quality products available on the market.