- Home

- HDC Quality Assurance

Quality Assurance at HDC: Ensuring Excellence in Custom Metal Products

At HDC, quality is more than a promise—it's our fundamental principle. We meticulously integrate quality assurance into every phase of our custom metal production process, from initial design to final delivery. This unwavering commitment ensures that each product we craft meets the highest standards of precision and reliability, providing you with excellence you can trust.

Quality Built In, Not Added On: HDC's Manufacturing Philosophy

At HDC, we don’t see quality as just another item on a checklist—it’s at the heart of everything we do. From the very start, when we’re brainstorming your custom metal product, we’re thinking about how to make it the best it can be. We work closely with you during the design phase, making sure every detail aligns with your vision and our high standards.

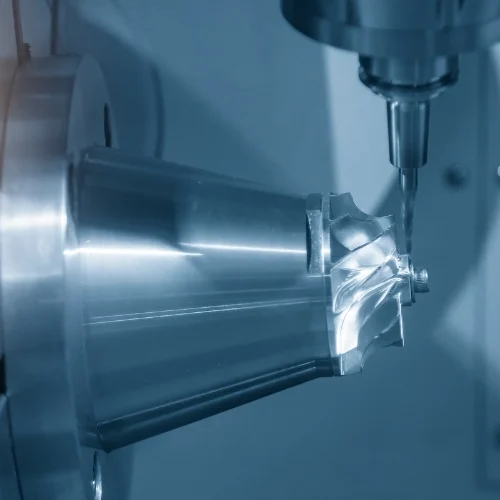

We carefully choose the raw materials, knowing that great products start with great ingredients. Our skilled technicians use top-of-the-line machinery to bring your ideas to life, paying close attention at every step. We build quality checks into each phase—whether it’s validating designs, precision machining, ongoing inspections, or thoughtful packaging. By catching potential issues early, we avoid problems down the line.

This thorough, start-to-finish commitment means that the final product doesn’t just meet your expectations—it goes beyond them. We’re dedicated to delivering exceptional quality and reliability in every piece we create for you.

HDC's Commitment to Excellence in Custom Metal Production

Struggling to find consistent quality in custom metal production? Inadequate standards can derail your projects. At HDC, we integrate rigorous quality assurance into every step, delivering the excellence you need.

HDC’s comprehensive quality assurance process spans every phase—from design to delivery. Utilizing advanced equipment and skilled professionals, we ensure precision and reliability in each custom metal product, providing exceptional results tailored to your needs.

Quality Assurance at Every Step

Discover how HDC integrates quality into every phase of custom metal production, ensuring excellence from design to delivery.

1. Design Phase

2. Raw Material Handling

3. Precision Production Equipment

4. Machining Process

5. Quality Inspection

6. Surface Finishing

7. Packaging and Transportation

Frequently Asked Questions

We totally get how crucial it is to meet your exact specs. From the get-go, we focus on clear and open communication. Our design team works closely with you to fully understand your needs. Using advanced CAD/CAM software, we create precise models and run simulations to make sure everything matches your expectations before we kick off production.

Quality is at the core of everything we do. We comply with international quality standards, including ISO certifications. This commitment ensures all our products meet strict quality requirements, providing you with reliable and high-quality custom metal solutions you can trust.

Absolutely! We're experienced in meeting various industry-specific standards and regulations. Whether you need materials that comply with certain certifications or products that meet specific guidelines, we'll tailor our processes to fulfill your exact requirements.

We source raw materials only from reputable suppliers who meet our strict criteria. Each batch goes through rigorous inspections using advanced equipment like spectrometers to verify metal composition and quality. This ensures your products are made with top-notch materials.

Consistency is key for us. We achieve this through standardized procedures and continuous process optimization. We keep meticulous records and apply the same rigorous quality checks to every batch. This way, you can expect uniform quality across all your products.

If any problems come up, we act quickly to fix them and keep you informed every step of the way. Our goal is to resolve any issues promptly to prevent delays and ensure you're completely satisfied with the end result.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!