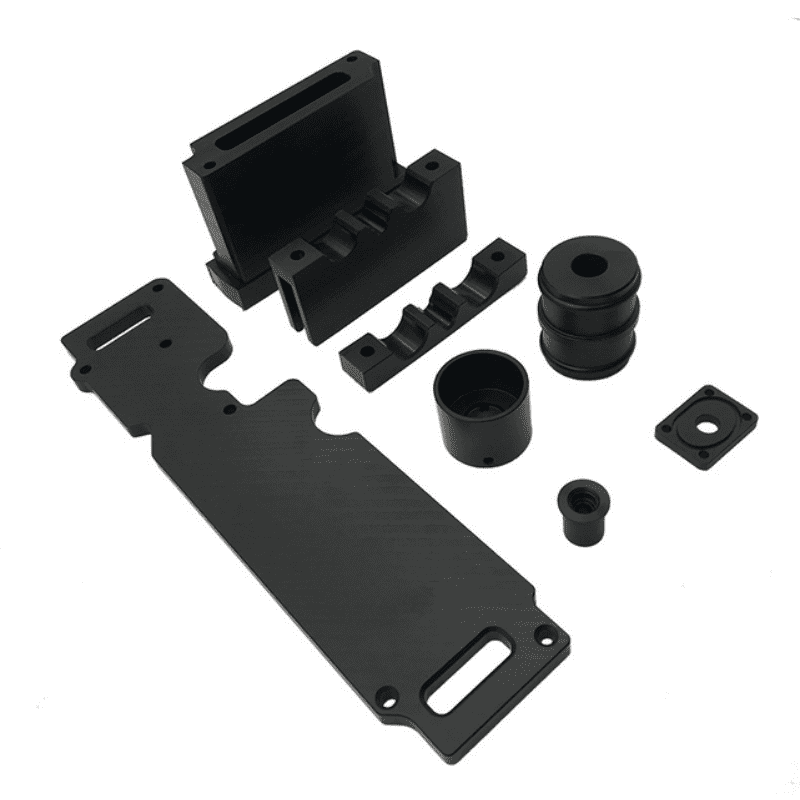

PEEK CNC Machining

HDC for PEEK CNC Machining

Polyetheretherketone or more commonly known as PEEK is an excellent thermoplastic that has multiple CNC machining applications. PEEK offers high rigidity, is resistant to temperature, chemical and moisture conditions, and is light in weight. Due to all these qualities PEEK CNC machining is very popular in various industries. Here is why you should choose us for precision CNC machining of PEEK

Why Choose Us

Adherence to Quality Standards

We have successfully acquired the prestigious ISO 9001 certification that indicates our commitment to quality standards. As a result of our high standards, we deliver only the best and highest quality of PEEK CNC machined parts.

Most competent rates

We have invested substantial time in research of manufacturing the most cost-effective PEEK parts for our clients. Therefore, we will offer you the most competitive rates for the PEEK CNC machining services. Furthermore, you will save a great deal of amount as there will be no reworking required on our delivered products.

Option of custom design

At HDC, we have a dedicated design team that works day and night on the PEEK custom designing. So, we can design custom parts for you on your request and based on the parameters provided by you. You can use these custom parts as prototypes. In addition, we also develop sample designs for you before beginning the batch production of PEEK CNC milling parts.

Your design is safe with us

Our clients are our first priority. Therefore, we always keep your design safe with us and do not share it with any other client. Also, we work closely with our clients so that they can convey their requirements in detail. Once with our design team, the requirements and specifications of your design stay safe.

Available materials

PEEK has two main types of variants that are majorly used in the industry i.e. PEEK and 30% Glass Filled PEEK. There is another classification of PEEK parts namely the industrial grade PEEK and medical grade PEEK. Each of the grades have their over specific properties. The density of PEEK ranges from 1.23 g/cm3 to 1.32 g/cm3. Different grades of PEEK offer wonderful yield strength (tensile) of around 14,000 psi. Moreover, PEEK CNC machined parts operate perfectly well over a large range of temperatures.

FAQ

Is PEEK suitable for CNC machining?

Yes. PEEK is one of the best materials for CNC machining. This is because with the diverse applications of PEEK and its physical and chemical properties, it becomes ideal for CNC machining applications.

What are the advantages of machining PEEK?

PEEK CNC machining offers multiple benefits like tight tolerances, high repeatability, high precision, permitting faster machining than many other materials, load resistant, and heat resistance to a certain level. All these benefits of machining PEEK make it an ideal choice for many applications.

What are the main applications of CNC Machined PEEK parts?

CNC machined PEEK parts have a diverse range of applications ranging from the Aerospace Industry to the healthcare and dentistry industry. Other industries that mainly use the PEEK CNC milling parts include the electronics industry, the energy industry, the automotive industry, etc. Main CNC parts of PEEK include bearings, rollers, washers, implants, dental caps, orthopedic devices, etc.

Will HDC help in selecting the right PEEK grade?

Yes. HDC will help you in selecting the ideal PEEK grade for your CNC machining PEEK part. You will just have to share your requirements regarding the application of your part and other specifications. In fact, our design team will directly contact you and obtain all the relevant information before starting the machining process. Therefore, we will select the best PEEK material for you and inform you why it is the best for your requirement.

[toc]