Investment Casting Part Aluminum/Steel/Superalloy/Brass Custom Closed Impeller

Custom Product Details

| Model NO. | HDCICI001 |

| Style | Investment Casting Closed Impeller |

| Material | Aluminum, Aluminum Alloy, Stainless Steel, Steel Alloy, Superalloy, Brass |

| Finish Type | Unfinished, Polished, Anodized, Electrophoretic Coated, Powder Coated, Galvanized, Chromed, Black Oxided |

| Available Size | / |

| MOQ | 50 Pcs |

| Custom Logo | Available |

| Origin | China |

| Packaging & Delivery | |

| Shipping Option | Courier, Air, Sea, Railway Express, EXW, FOB, CIF, DDU, DDP |

| Delivery Date | 25-30 days |

| Transport Package | Customized, Carton, Pallet |

Unlock peak hydraulic efficiency and long-term turbomachinery reliability with this investment-cast closed impeller. Precision-engineered for pumps, compressors, and high-performance rotating equipment, this component transforms fluid energy with aerodynamic precision—delivered with the geometric freedom and material integrity only investment casting can provide.

Multi-Alloy Material Selection: Available in lightweight aluminum, high-strength steel, corrosion-resistant brass, or advanced superalloy—each precision-selected to match specific operating pressures, fluid compatibility, temperature extremes, and weight optimization targets.

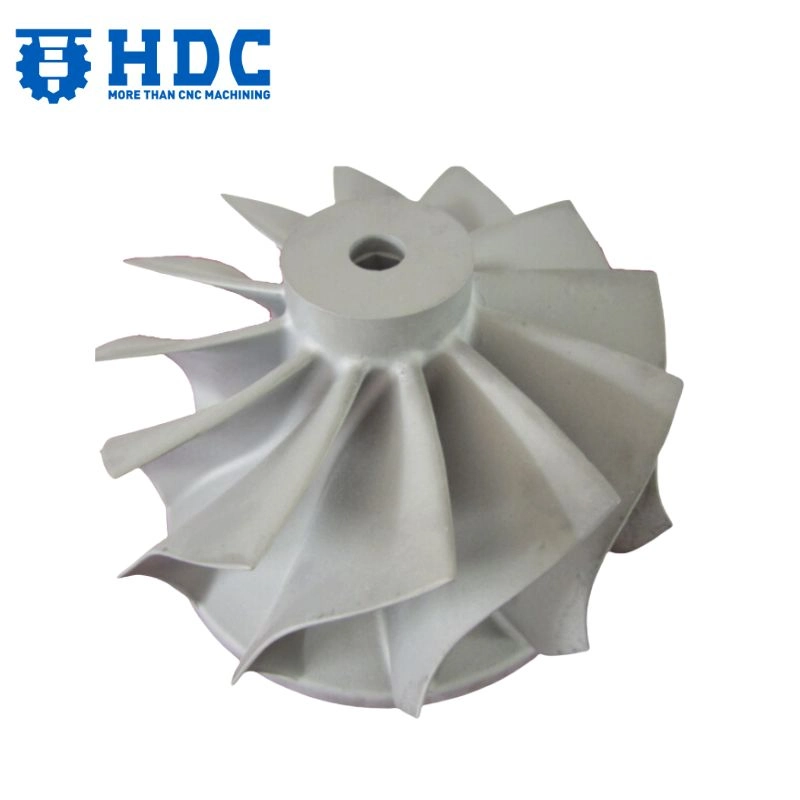

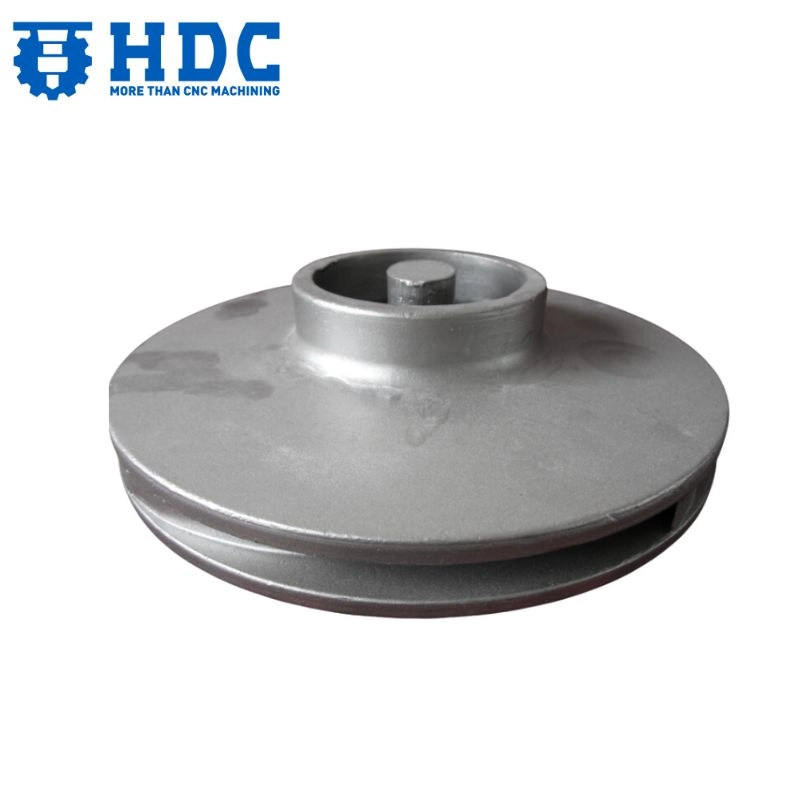

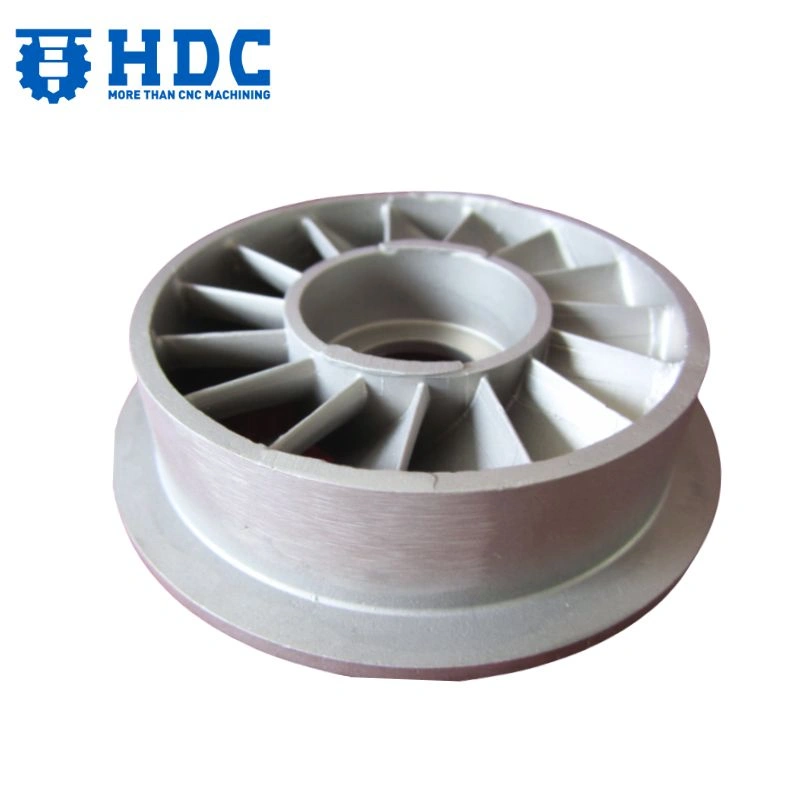

Investment-Cast Integral Blade Architecture: Precision investment casting enables the formation of complex, fully shrouded blade passages with continuously blended fillet radii and smooth flow surfaces unattainable through five-axis machining or fabricated assemblies—eliminating weld distortion and preserving aerodynamic contour fidelity.

Smooth, Unobstructed Flow Channels: Integrally cast vanes and contoured hub-to-shroud transitions maintain laminar flow characteristics, minimizing turbulence, cavitation potential, and hydraulic losses across the entire operating curve.

Optimized Rotational Balance: Near-net-shape casting accuracy combined with precision CNC balancing ensures concentricity, consistent blade pitch, and minimal residual unbalance—reducing vibration, extending bearing life, and maintaining efficiency at rated speeds.

Fully Customizable Performance Parameters: Manufactured to customer-specific vane counts, exit angles, hub profiles, and diameter constraints—accommodating everything from high-flow/low-head water pumping to high-pressure gas compression and cryogenic fluid transfer.

Application-Specific Surface Engineering: Available with optional hard coatings, erosion-resistant claddings, or chemical barrier treatments—providing lasting protection against abrasive slurries, corrosive media, and high-temperature oxidation.

Applications:

Centrifugal Pumps: Ideal for process water, chemical transfer, HVAC circulation, and municipal boosting applications requiring sustained hydraulic efficiency and maintenance interval extension.

Industrial Compressors: Essential for air separation, refrigeration, and pneumatic conveying systems demanding oil-free operation and continuous-duty pressure generation.

Turbocharger & Supercharger Assemblies: Suitable for high-speed rotating assemblies requiring verified burst containment and minimal polar inertia for transient response.

Aerospace & Marine Propulsion: Engineered for fuel pumps, cooling circuits, and ballast systems where weight reduction and corrosion resistance intersect with performance certification requirements.

More than a rotating vane assembly, this investment-cast closed impeller is the fluid-dynamic heart of your turbomachinery—translating rotational input into precisely metered pressure and flow with every revolution. Whether you’re engineering high-efficiency water infrastructure or next-generation aviation fuel systems, it’s the component that proves hydraulic performance begins with precision-cast, integrally bladed continuity.