Precision CNC Titanium Parts Manufacturer

HDC has been machining titanium with advanced equipment and unmatched material expertise for over 10 years.

We have overcome various challenges in machining this premium metal. The components we produce are trusted by global clients and widely used in fields requiring an exceptional strength-to-weight ratio, such as aerospace, sports equipment, and medical devices.

Contact us today with your specifications, and we’ll offer a comprehensive quote within 24H.

Industries We Serve

Racing

HDC machines critical titanium parts for high-end racing vehicle modification, helping to reduce weight, improve driving experience, and enhance stability during intense driving.

Medical

Relying on titanium’s biocompatibility nature and our advanced 5-axis CNC machining center, we are capable of producing medical implants and surgical equipment with intricate designs.

Sports Gear

Titanium alloy has become a common choice in the field of high-end sports equipment and consumer electronics with its excellent strength-to-weight ratio and unique texture.

Titanium Materials We Machine

Pure titanium and Gr5 are the most commonly used titanium materials in HDC. If you need different materials, we can also offer customized solutions.

Gr1(TA1), Gr2(TA2), Gr3(TA3), Gr4:

These materials contain more than 99% titanium and are often referred to as pure titanium. Compared with titanium alloys, they have better machinability and formability, ranking among the easiest-to-process types of titanium metal.

They are widely used in chemical equipment, medical implants (such as bone plates and screws), and consumer electronics casings. Among them, Gr2 is the most commonly used and cost-effective grade of pure titanium.

Gr5 is the absolute mainstay in titanium alloy processing, offering the best balance of comprehensive properties (strength, toughness, corrosion resistance, weldability) and machinability. As a result, it is the most widely used, accounting for over 70% of titanium alloy processing.

The processing technology for Gr5 is mature, with a wealth of data and experience available for reference. It is widely used in aircraft structural components, engine parts, medical implants, high-performance sports equipment, and more.

Surface Treatments Options

At HDC, we offer a wide range of finishing options for titanium products to satisfy aesthetic requirements and enhance functionality.

Pickling

Sand Blasting

Anodizing

Electroplating

CNC Titanium Parts

HDC manufactures titanium products from small to large, enabling complex designs that are not possible with traditional machining methods.

Why Choose HDC

Advanced Equipment: Equipped with modern 5-axis, 4-axis, and 3-axis CNC machines, we are capable of efficiently and precisely machining complex titanium alloy parts, reducing setup times and shortening delivery cycles.

CNC Titanium Expert: With extensive experience, we optimize tool selection, spindle speed, feed parameters, and process flows for customers to ensure exceptional machining results.

Global Service: Our professional sales team efficiently handles logistics, documentation, and communication, making global procurement simple and reliable.

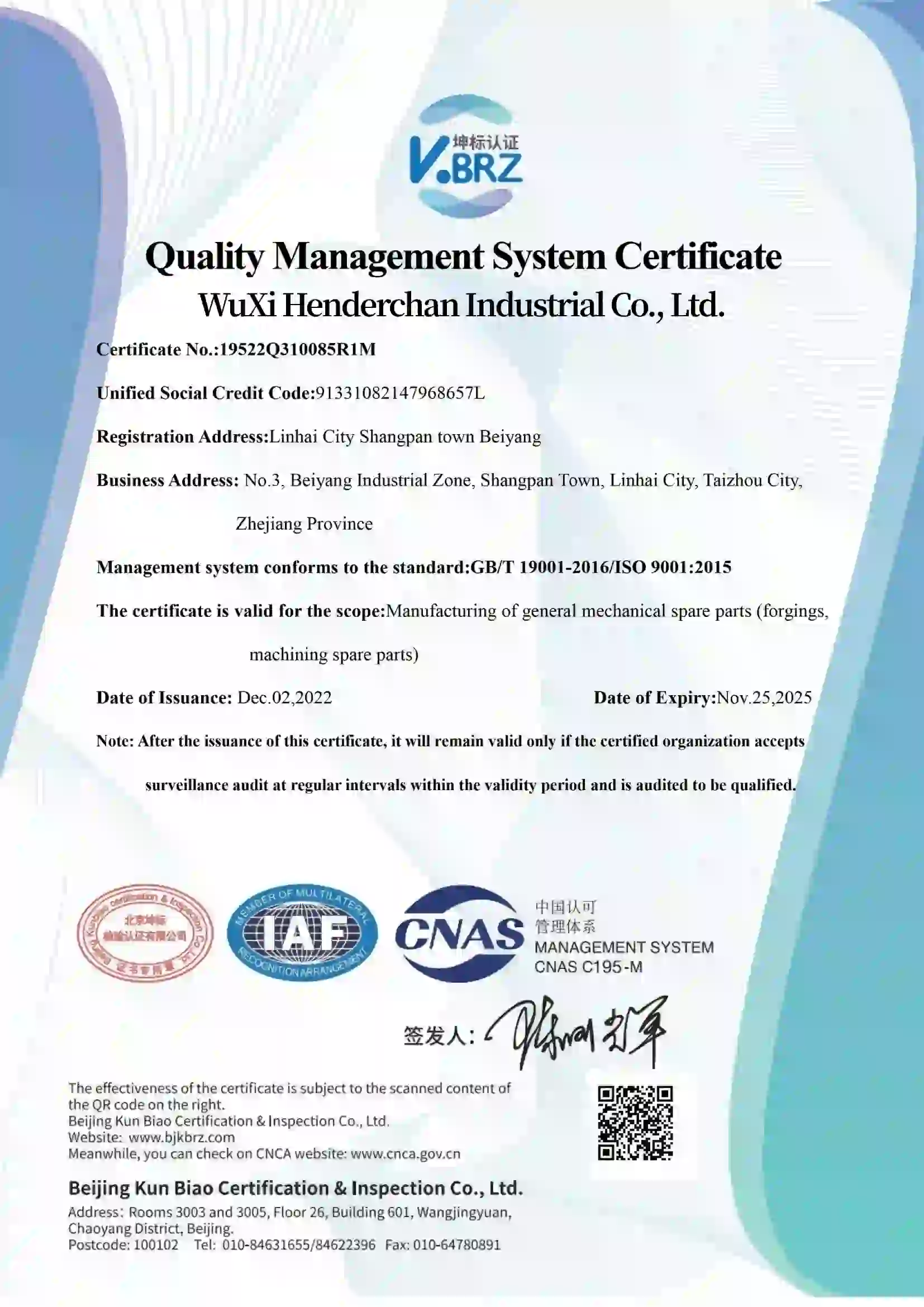

Certified Factory: HDC operates under a stringent quality management system, backed by ISO certification, ensuring process consistency and traceability.

Trusted Partner: We are committed to building long-term partnerships through timely delivery, transparent communication, and solutions tailored to your project needs.

Customization Products With a Simple Quote!

We regularly machine all major grades, including commercially pure (CP1-CP4), Grade 5 (Ti-6Al-4V), Grade 23 (Ti-6Al-4V ELI), and other alloys. Our spectral analysis ensures material conformity.

Lead times vary based on complexity and volume. Prototypes can ship in as little as 2-3 weeks; production batches typically take 4-8 weeks.

Absolutely! Our flexible setup excels at low-volume, high-complexity prototypes and high-volume production runs. We optimize processes for cost-efficiency at any scale.

We implement a rigorous, multi-stage QC process:

- Material certification verification

- First-article inspection (FAI) with CMM

- In-process checks & SPC for critical dimensions

- Final batch inspection (hardness, key dimensions)

- Full traceability supported by ISO 9001.

Yes, our advanced 5-axis CNC machines specialize in complex contours, deep cavities, thin walls, and tight-tolerance features common in aerospace and medical titanium components.

We prefer 3D CAD (STEP, IGES, SLDPRT) and 2D drawings (PDF, DWG). Our engineering team can assist with design optimization for manufacturability (DFM).

Yes! We supply full material traceability and can provide inspection reports upon request. All documentation complies with international standards.

Our dedicated sales team manages all logistics (air/ocean), customs clearance, and documents (Packing List, Commercial Invoice, COO, etc.) – ensuring smooth delivery worldwide.

First, titanium has a higher material cost, usually more than 10 times that of aluminum. Besides, CNC machining titanium demands specialized tooling, lower cutting speeds, and rigorous process control to prevent work hardening. All these factors result in a high price of CNC titanium parts.