Custom Aluminum Forging Parts Manufacturer

HDC is your trusted aluminum forging products provider with over 10 years of expertise. We can forge aluminum parts from 0.01 kg to 30 kg with tens of grades of aluminum, which is widely used in high-performance racing vehicles.

With our precision die forging process and comprehensive one-stop solution tailored based on specific requirements, you can custom aluminum forgings with no worries and focus on your professional field to rocket your business.

Applications of Forging Parts

Automotive

HDC produces reliable chassis suspension components for a stable and comfortable driving experience during high-intensity racing.

Motorcycle

Our handle, brake, and wheel series aluminum forging motorcycle accessories ensure a precise control experience and excellent wright reduce.

Consumer Goods

We forge high-performance aluminum components for applications where the strength-to-weight ratio matters, such as camping and hiking equipment.

Aluminum Alloys We Forge

We handle aluminum alloys from the 2000 series to the 7000 series for forging, satisfying various needs for custom aluminum forgings.

2000 series aluminum alloy has high strength and good heat resistance but general corrosion resistance, and is usually used for hot forging.

- 2024: One of the most classic aerospace aluminum alloys. High strength, good toughness and excellent fatigue performance.

The 6000 series aluminum alloy has excellent overall properties, but the strength is lower than that of the 2000 and 7000 series.

- 6061: One of the most widely used forged aluminum alloys. Excellent comprehensive performance, good corrosion resistance and good weldability. It is widely used in various structural parts.

- 6082: The most commonly used 6000 series forging alloy in Europe, with performance very similar to 6061 and slightly higher strength than 6061

The 7000 series aluminum alloy has the highest strength of all wrought aluminum alloys, has an excellent strength-to-weight ratio after aging treatment, but has average corrosion resistance and is difficult to forge.

7075: The most well-known ultra-high-strength aluminum alloy, which is extremely strong (T6 state), but is not as tough and resistant to stress corrosion as improved versions such as 7050/7055.

Post Treatments

Our aluminum forging service includes comprehensive post-treatment options for high-quality, out-of-the-box products.

Heat Treatment

Sand/Bead Blasting

Pickling

CNC Finishing

Anodizing

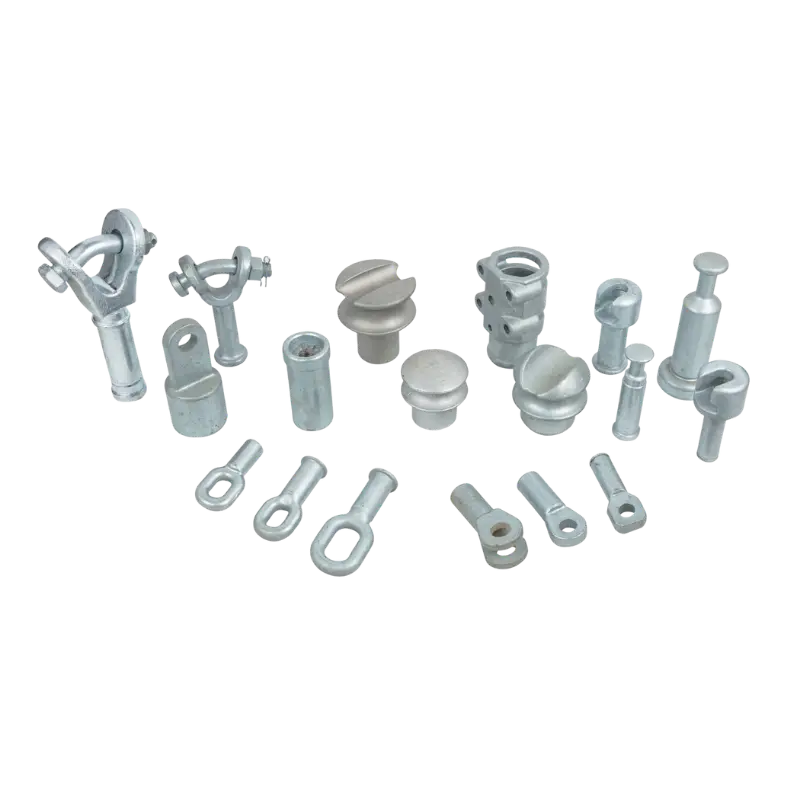

Aluminum Forging Products

Our main business area focuses on high-strength forging and precision CNC finishing of auto and motorcycle parts.

Why Choose HDC

Whole Process Capability: HDC handles the process from forging, post treatments, packing, and shipping under one roof.

Mass Production Capability: We have over 50 forging presses from 160T to 4000T, enabling us to complete high-volume production tasks on schedule.

Comprehensive Support: We offer end-to-end assistance from design and material selection to process optimization, with rapid response within 24 hours and multilingual services.

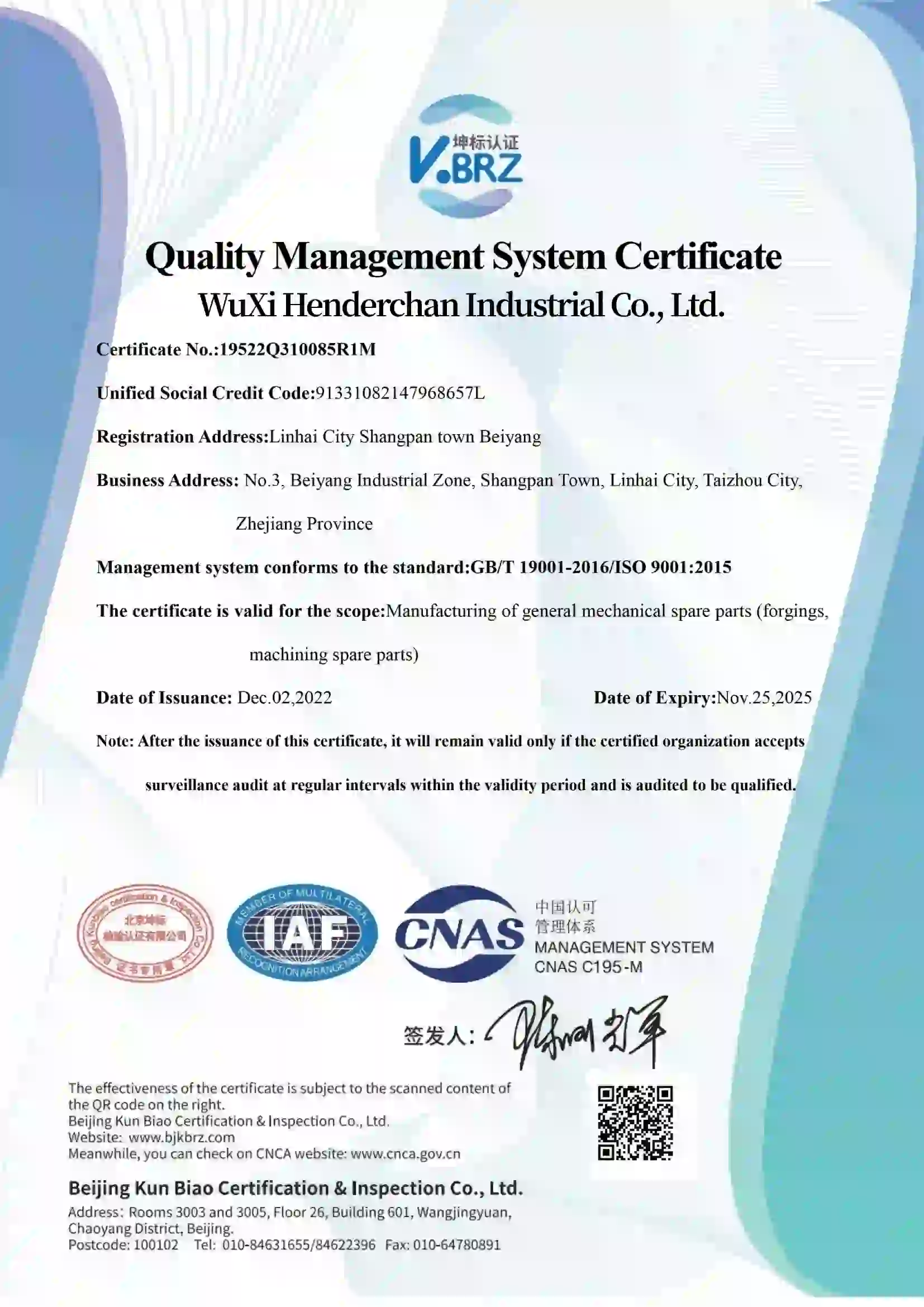

Strict Quality Control: Our quality control process goes through the whole manufacturing process, from material verification, dimensional inspection, defect detection, to functional testing.

Aluminum Alloy Comparison

| Property | 5xxx Series (Al-Mg) | 6xxx Series (Al-Mg-Si) | 2xxx Series (Al-Cu-Mg) | 7xxx Series (Al-Zn-Mg-Cu) |

|---|---|---|---|---|

| Representative Grades | 5052, 508 | 6061, 6082 | 2014, 2024 | 7050, 7075 |

| Strength | Low to moderate | Moderate | High | Very high |

| Corrosion Resistance | Excellent | Very good | Poor | Moderate |

| Toughness/Fracture Toughness | Low to moderate | Good | High | High |

| Thermal Stability | Limited (≤150°C) | Good (≤200°C) | Very good (≤250°C) | Moderate (≤200°C) |

| Weldability | Excellent | Very good | Poor | Poor to moderate |

| Forging Characteristics | Excellent | Very good | Moderate | Difficult |

| Relative Cost | Lowest | Moderate | High | Highest |

| Heat Treatability | Non-heat-treatable | Heat-treatable | Heat-treatable | Heat-treatable |

| Stress Corrosion Cracking (SCC) Resistance | Very good | Good | Moderate to poor | Moderate |

Customization Products With a Simple Quote!

We can manufacture aluminum forgings with a weight range from 0.01kg to 30kg. The specification depends on the specific products' thickness and geometries.

The most commonly used grades are listed in the above material section. For more details, please contact us via email.

Yes, for a production run that requires mold developing, there is an MOQ, and the specific quality is negotiable.

Yes, we offer prototypes based on your requirements.

Yes, all customers are welcome to see our factory, please contact us in advance to get an appointment.