Forging Aluminum Wheel Spacer & Adapter Manufacturer

HDC specializes in high-precision, forged aluminum wheel spacers tailored to your exact vehicle specs. Engineered for strength, safety, and style — from daily drivers to performance builds.

- Fully Customizable

- High Quality Material

- ISO Certified Quality

Our Key Advantages

High quality aerospace-grade 7075-T6 is available, suitable for high-performance modifications

We use hot forging for billet processing to improve mechanical strength of the wheel spacer.

CNC precision machining ensures tight tolerances for a perfect fit with all types of wheel hub specifications

Fully Customizable

We offer a wide range of custom options to match your exact vehicle setup and styling preferences.

Customization Options

| Material | 7075-T6 / 6063-T6 Forged Aluminum |

| Bolt Pattern | Any configuration (e.g. 4×100, 5×114.3, 6×139.7) |

| Center Bore | Precise machining to match hub diameter |

| Thread Pitch | M12x1.5, M12x1.25, M14x1.5, or custom |

| Thickness | From 3mm to 60mm |

| Spacer Type | Slip-on or bolt-on; hub centric or lug centric |

| Surface Finish | Anodizing: Type II, Type III |

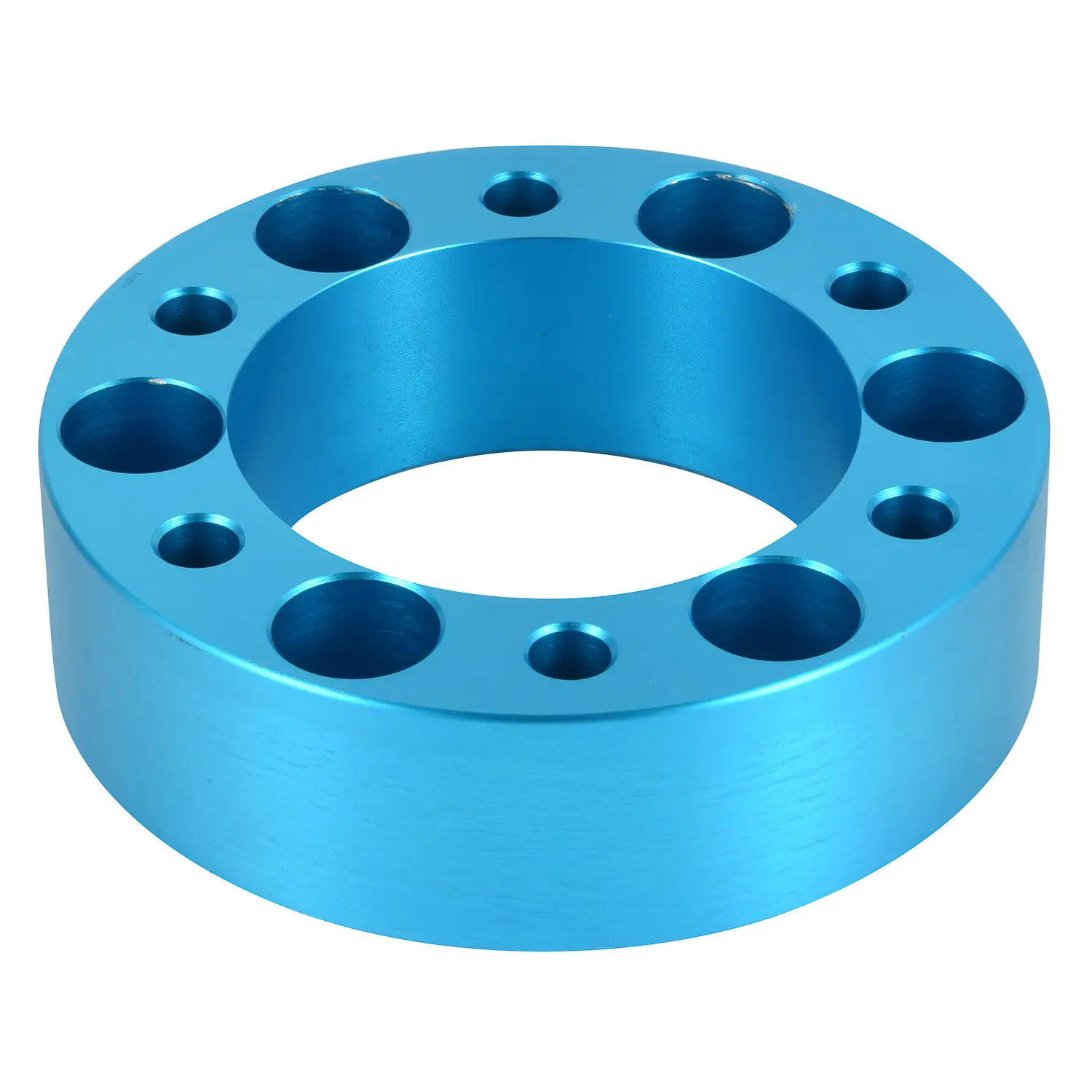

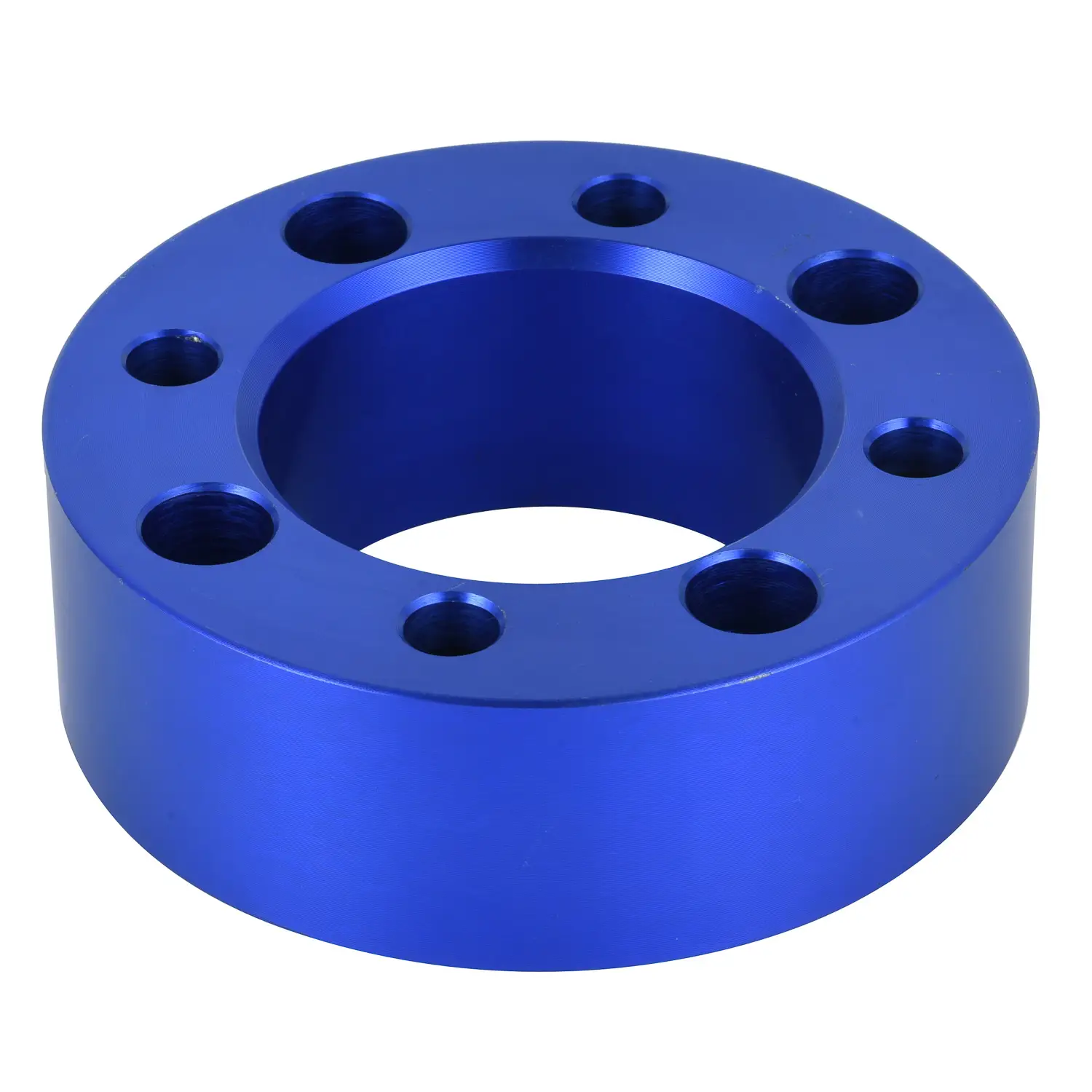

| Anodized Colors | Black, red, blue, silver, gold, orange, and more |

| Logo Engraving | Optional laser-marked branding or text |

Wheel Spacer by Type

Explore our wheel spacers categorized by structure and fitment style.

Slip On - Hub Centric

Slides over the hub and centers on the bore, ideal for small adjustments with OEM fit.

Bolt On - Hub Centric

Mounts securely with built-in studs, perfect for thicker applications and tight tolerance fit.

Slip On - Lug Centric

Centers using lug bolts, commonly used with aftermarket wheels where hub fit is not critical.

Bolt On - Lug Centric

Lug-centric with studs for easy installation, used when hub matching is not required.

Wheel Spacer by Color

We offer a variety of anodized finishes to match your vehicle’s style or accent color.

Wheel Spacer by Thickness

We offer custom wheel spacers in any thickness from 3mm to 100mm to meet your clearance or stance requirements. Below are popular sizes we produce.

Wheel Spacer by Bolt Pattern

Find the perfect fit for your vehicle with bolt pattern-specific spacers. Choose from a variety of lug configurations for direct fit or conversion use.

Wheel Spacer by Vehicle Brand

We specialize in custom wheel spacers tailored to specific vehicle models. Below are some of the most commonly requested brands we serve.

Tesla

For Model 3/Y with 64.1mm hub and M14x1.5 thread.

Ford

Fits F-150, Ranger with 6×135 or 8×170 patterns.

Honda

5×114.3 bolt pattern with M12x1.5 thread.

BMW

5×120 PCD and 72.6mm center bore fitment.

Nissan

Supports 4×114.3 or 5×114.3 with M12x1.25 thread.

Subaru

Works with 5×100 and 5×114.3 layouts.

Mercedes-Benz

5×112 bolt pattern and 66.5mm hub bore.

Audi

5×112 PCD and M14x1.5 thread compatibility.

How to Choose The Right Wheel Spacer

Choosing the compatible wheel spacers is essential for a safe and comfortable driving experience. To achieve that, you may need to confirm the following 6 parameters of your wheel sets.

1. Bolt Pattern

Bolt pattern refers to the number of bolt holes on the wheel hub and the diameter of the circle on which these holes are distributed, such as 4×100, 5×114.3, 6×139.7.

It must exactly match the layout of the wheel hub (axle head). If the bolt pattern does not match, the wheel cannot be installed, and forced installation may pose safety risks.

For wheel hub modifications that require adapting to a different bolt pattern (e.g., converting from 4-lug to 5-lug, or from 5×120 to 5×114.3), conversion spacers must be used. These spacers are also known as adapter flanges.

You can find the information by checking the vehicle manual or the back of the wheel hub. You can also measure it by following this video tutorial: How to Find your Wheel Bolt Pattern

2. Center Bore

The center bore is the hole at the center of the wheel hub that aligns with the vehicle’s axle for precise centering.

When using hub-centric spacers, the center bore must match the axle exactly; otherwise, it may cause wheel misalignment, vibration, and loose lug nuts.

3. Thread Pitch

Thread pitch refers to the diameter and spacing of your lug bolts — for example, M12x1.25 or M14x1.5. It’s crucial that the spacer’s studs (or the nuts you use) match your vehicle’s original thread pitch exactly.

Using the wrong thread pitch can strip the threads, prevent proper tightening, or cause the nuts to come loose. Always check your car manual or remove a lug bolt and look at its markings.

4. Thickness

Thickness determines how far the wheels are pushed outward from the hub. Choosing the right thickness can improve wheel clearance, achieve a flush stance, or help fit aftermarket brake kits.

Too thin, and the spacer may not resolve clearance issues. Too thick, and the wheels may stick out past the fenders or rub against suspension parts. Common sizes are 10mm, 15mm, 20mm, and 25mm.

For small adjustments (e.g., 10–15mm), a slip-on spacer is usually enough. For thicker setups (20mm+), use a bolt-on spacer for better strength and safety.

5. Hub Centric vs. Lug Centric

A hub-centric spacer centers the wheel using the axle hub. This ensures perfect alignment and is usually preferred for OEM wheels and high-speed driving. Lug-centric spacers center the wheel using the lug bolts — suitable for some aftermarket wheels with oversized center bores.

Hub-centric wheel spacers have a cylindrical protrusion in the center, while Lug Centric ones feature a smooth hole. You can check the comparison images we prepared to quickly understand their differences.

If your wheels are lug-centric, it’s a good idea to use hub rings to improve alignment. Whenever possible, choose hub-centric spacers for better stability and balance.

6. Slip-on vs. Bolt-on

Slip-on spacers slide over the existing studs and are held in place by the wheel and lug nuts. They’re simple and work well for thinner sizes, but only if you have enough thread engagement.

Bolt-on spacers, on the other hand, bolt directly to the hub and come with their own studs to mount the wheel. These are recommended for thicker spacers (usually 20mm and above), or when converting bolt patterns.

Needs Custom Made Wheel Spacer?

Our engineers support motorsport, off-road, and show car builds. Contact us for technical advice or a personalized quote.

FAQs

What types of custom wheel spacers does HDC offer?

We provide custom spacers with various bolt patterns, center bores, thicknesses, materials (6061-T6 / 7075-T6), colors, and surface finishes. We also accept production based on drawings or physical samples.

Do you support low-volume orders?

Yes. Small batch orders are accepted for sampling, after-sales service, or niche market demands. Minimum order quantities depend on the specification—please contact us for details.

What is the customization process?

You send specs or drawings → We confirm details and quote → Sample or batch production → Inspection and shipping.

What’s the typical lead time?

Samples usually take 5–7 days. Bulk orders take around 15–25 days depending on quantity. Custom finishes may require extra time.

How does HDC ensure product quality?

We use aerospace-grade forged aluminum, CNC machining, and strict quality control, including dimension checks, thread inspection, hardness testing, and anodizing thickness verification.

How do you ship orders?

We offer sea freight, air freight, and international courier shipping. Delivery can be arranged to major ports or your specified address.

Do you offer after-sales support?

Yes. We stand behind every order. If you encounter quality issues, incorrect specs, or shipping damage, please contact us—we’ll resolve it promptly.