Forged Power Line Hardware & Electrical Fittings Manufacturer

HDC serves the electrical industry with precision forging and hassle-free customized service. We forge every essential part you need to build a high-quality powerline.

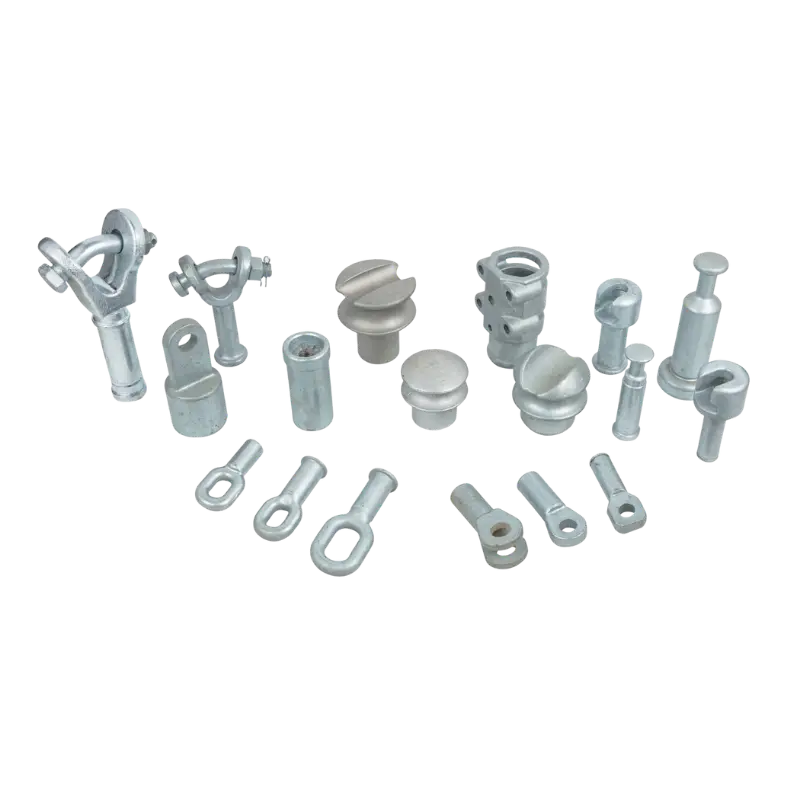

Electrical Fittings We Fabricate

From lugs to clamps, HDC customizes fittings from small to large to meet your project specifications.

Line Connecting Fittings

The line connector is designed to connect wire with Insulator strings, towers, or other hardware to transmit mechanical stress. HDC forges clevis, shackle, and socket eye, etc, with high-strength metal to ensure a safe connection.

Conductor Fittings

At HDC, we forge these fittings from copper or aluminum to meet the electrical conductivity and mechanical strength requirements at connection points between conductors or between conductors and equipment terminals.

Suspension & Tension Fittings

Just as the name indicates, these fittings are used to support the wire’s weight or tension strength to ensure the stability of a powerline system. We can fabricate them with high-tension strength carbon steel and aluminum alloy.

Grounding & Earthing Fittings

Grounding fittings, like ground clamps and bonding lugs, can be found in every electrical system. They protect the power line during lightning strikes and faults by dissipation current to the ground.

Mounting & Structural Hardware

This is a general term for fittings that help to support, install, and fix electrical equipment, such as brackets, flanges, hangers, bolt plates, and link fittings. You can customize any of them with HDC’s expert forging service.

Why Choose HDC

Why you need HDC to build your electrical fittings? Here are the answers.

Near-Net Shape Forging

HDC is an expert in precision close die forging. This is an advanced forging process that enabled us to forge electrical fittings near-net shape, which significantly reduces post-processing cost.

Wide Range of Material

We have over 20 types of material in stock, including aluminum, steel, and copper. Each batch of material is purchased from a reliable factory and comes with certificates.

Mass Production Capability

HDC equipment with over 40 forging presses and screw presses, as well as an automated forging production line, allows us to handle large orders in a short period.

Global Service

HDC provides multilingual support to ensure smooth and barrier-free communication. We also export to most countries worldwide, offering flexible shipping terms such as DDP, DDU, and FOB.

How HDC Fabricate Electrical Fittings

HDC has comprehensive capabilities to customize your electrical fittings from raw material to final product.

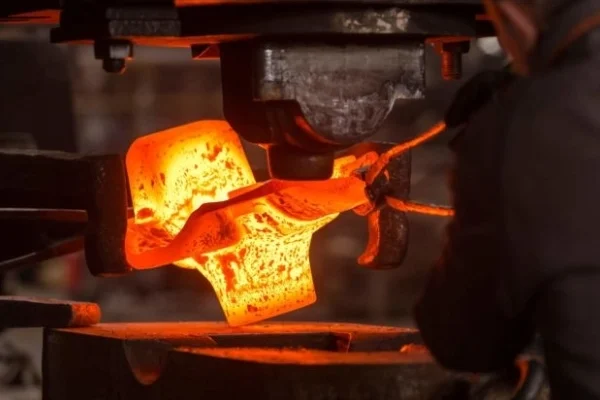

Close Die Forging

First, we fabricate the mold needed for close-die casting according to your drawing or sample with our in-house CNC capability. Once the mold is finished, we will test it and forge some samples for you. After you confirm the sample, we start mass production.

Heat Treatment

For some metals, heat treatment is a necessary step after forging, as it can refine the grain structure and improve overall properties of forged fittings, including hardness, tensile strength, and yield strength. HDC offers a series of heat treatments, such as tempering, quenching, etc.

CNC Machining

After the forging and heat treatment process, we remove burrs and oxides by sand blasting. Next, send the billet to our CNC workshop, the following steps commonly include milling, drilling, and tapping etc, ensuring dimensional accuracy and functional availability.

Check out our quality control methods for forging parts.

Material Available for Electrical Fittings

HDC offers over 20 grades of metals to customize fittings for your project.

Carbon steel is a common choice for powerline hardware, such as connectors, brackets, and bolt plates. It is easy to form with forging and has balanced strength and price. The con is that it may need additional surface finishing when used in outdoor or harsh environments.

HDC offers carbon steel in grades Q235, 20, 30, 40, and 45 for customized electrical fittings.

Stainless steel has a similar strength compared to carbon steel; Its most valuable feature is its corrosion resistance, but the price is too high. So stainless steel electrical fittings are mainly used in moist, corrosive environments, for instance, marine and southern regions.

As an expert in forging stainless steel, HDC offers 304 and 316 for custom projects.

Aluminum is much lighter than steel yet strong enough and naturally corrience resitence to maintain longevity in applications such as electrical fittings. It’s also one of the most suitable metals for forging. Despite the slightly higher price, it’s an ideal material for Insulator connectors, busbar connectors, conductor connection clamps, etc.

HDC offers both standard 6061, 6063, and aerospace-grade 7075 for customized electrical fittings.

Copper and its alloys have a long history in serving the electrical industry, mainly used to make wires due to their excellent conductivity. When talking about forged copper electrical fittings, they still shine in hardware like grounding parts, conductive clamps, connection terminals, connectors, and bonding lugs.

At HDC, you can get copper (C11000), bronze (C36000), and bronze (C83600) for customized fittings; other grades of copper alloys are also negotiable.

Custom Surface Finishes

HDC fabricates and finishes the product with comprehensive in-house capabilities.

HDC offers both electrical galvanizing and hot-dip galvanizing. Hot-dip galvanizing is mainly applied to large to medium steel parts, such as clevises, flanges, hangers, and link fittings. Electro galvanizing is usually used on bolts, nuts, and clips.

We apply polishing and passivation primarily for stainless steel fittings. Their main purpose is to remove oxide layer and enhance the corrosion resistance of stainless steel.

Our anodizing service includes color anodizing and hard anodizing. But for an electrical fitting, Type Ⅱ and Type Ⅲ hard anodizing is the first choice. It can form a thicker oxide layer on the surface of an aluminum fitting, enhance surface hardness, and corrosion resistance.

Technical Specifications

Get a full understanding of our manufacturing capabilities before requesting a quote.

| Forging Weight Range | 0.03 kg – 30 kg per piece |

| Forging Press Capacity | 160T – 4000T forging press and screw press |

| Maximum Dimensions | Up to 300 mm in outer diameter or 400 mm in length (depending on part geometry) |

| Applicable Materials | Carbon Steel, Alloy Steel, Stainless Steel, Aluminum Alloy, Copper Alloy |

| Material Grades | 20#, 40Cr, 42CrMo, SS304F, SS316F, 6061-T6, 7075, C11000 |

| Surface Finishes | Hot-Dip Galvanizing, Zinc Plating, Anodizing, Tinning, Polishing, Passivation |

| Tolerance | ±0.2 mm (after CNC machining) |

| Heat Treatment Options | Normalizing, Quenching & Tempering, Solution Treatment, Aging |

| Machining Capability | 3-axis / 4-axis / 5-axis CNC precision machining for tight-tolerance areas |

| Testing & Inspection | CMM dimensional inspection, hardness & tensile testing |

| Production Volume | Small to medium batch production (MOQ depending on part type) |

| Design Support | CAD/CAM design review, 3D modeling, material & process recommendation |

Need to build a Custom Fitting?

Reach out to HDC, then you get the most expert one-stop forging product solution you can find. Just send an email, our quote is free!

FAQs

What is an electrical fitting and its types?

Electrical fittings are metal components used to connect, support, or secure electrical systems such as power lines, grounding systems, and substations. Common types include clevises, shackles, brackets, flanges, clamps, and grounding connectors.

What is a shackle vs a clevis?

A shackle usually has a U-shaped body closed by a pin or bolt, allowing quick connection and disconnection.

A clevis also has a U-shape but connects with a pin through a mating part (like a tongue or eye), forming a more permanent and aligned joint.

Why is it called a clevis?

The word “clevis” comes from an old English term meaning “to fasten” or “to bind.” It describes the way the U-shaped fitting securely holds another component using a pin connection.

Why forge an electrical fitting instead of another process?

Forging creates a denser, stronger metal structure with better mechanical performance than casting or welding. It ensures higher strength, toughness, and reliability, essential for parts used in power transmission and structural applications.

Can HDC provide prototypes before mass production?

Yes. HDC can produce forged prototypes or small trial runs for testing and design validation before full-scale production.

Do you have an MOQ for custom electrical fittings?

Yes, since forging requires tooling and setup, we do have a minimum order quantity. The MOQ depends on the part’s size and complexity, and we’ll confirm it during quotation.