OEM Motorcycle Forging Parts Manufacturer in China

Capable of forging and CNC machining, HDC fabricates high-end OEM & modification motorcycle parts for motorcycle manufacturers around the world.

- Wide Range of Materials

- Competitive Price

- ISO & IATF Certified Factory

Why Forging for Motorcycle Parts

For motorcycle parts that aim for high performance and an exceptional strength-to-weight ratio, forging is the ideal method to consider.

Optimise Performance

Forged aluminum parts combine strength and lightness, built for the high-performance model.

Consistent Quality

Once a mold is built, you can consistently forge high-quality products at a high production rate.

Cost Effective

Despite the higher upfront cost, forging is way more cost-effective in mass production compared to CNC and casting

Optimized for Safety

Forged parts can bear high loads and intense impact, ensuring safety in high-speed racing.

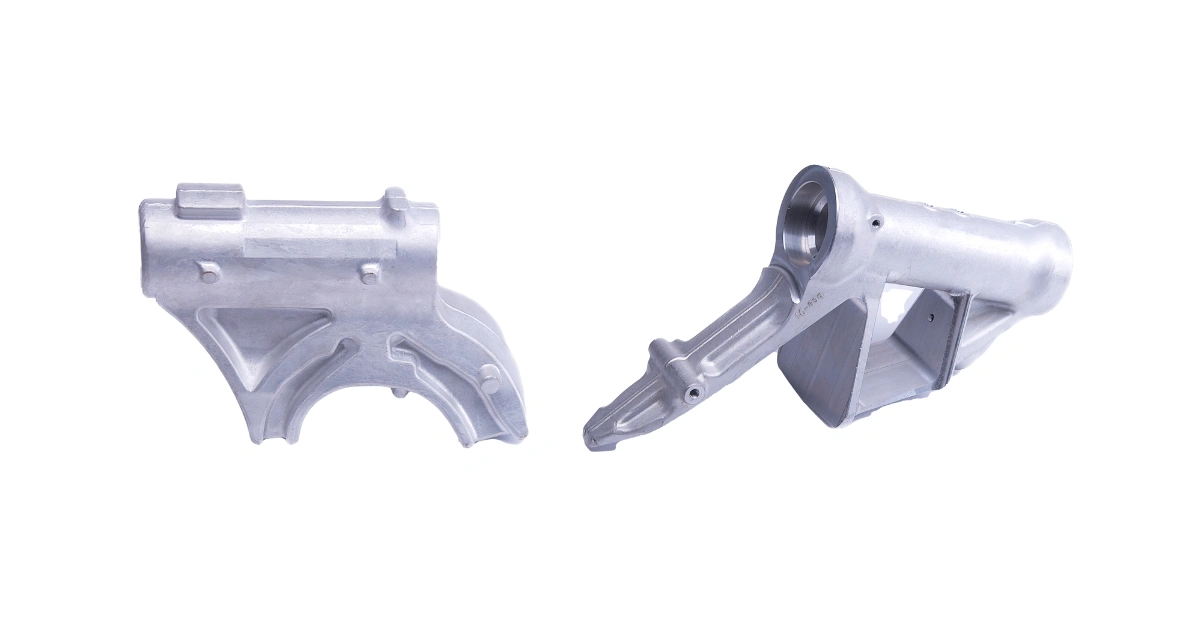

Types of Forging Motorcycle Parts

About 80% of our forging parts are made for motorsports. Here are some typical parts we fabricate for a motorcycle.

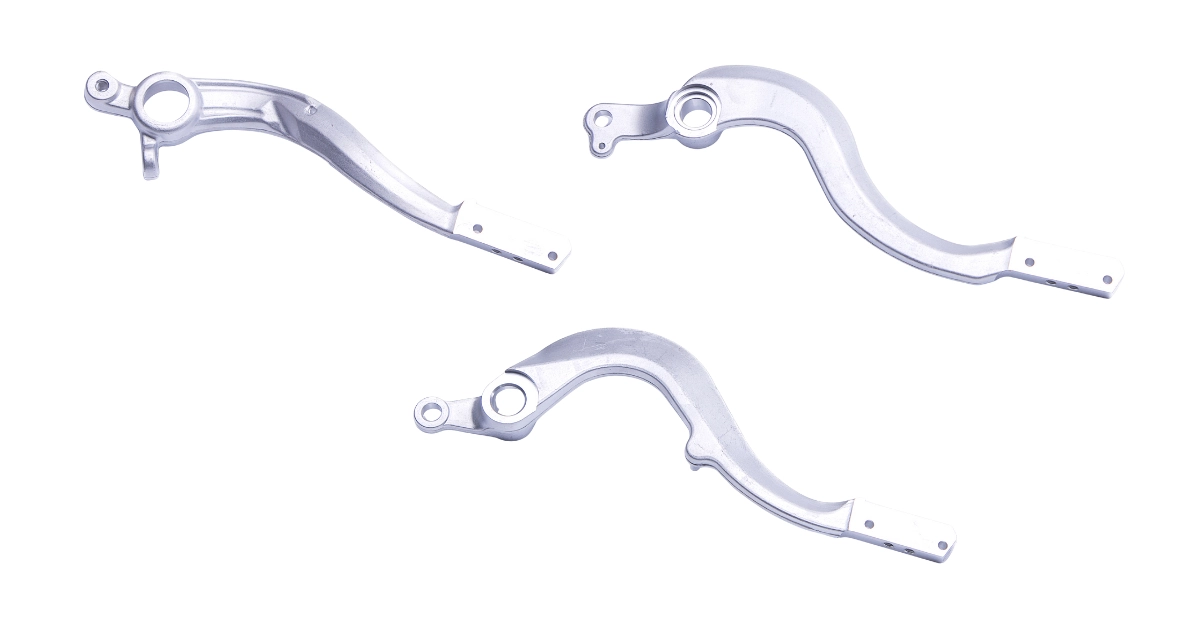

Control & Operation

Handlebar, Brake Handle

For motorcycle parts with a complex structure and curves to implement ergonomic design, close die forging is a highly recommended processing method.

As a near-net shape process, you can reduce post-machining while retaining high precision in shape.

Braking & Transmission

Wheel Hub, Brake Components

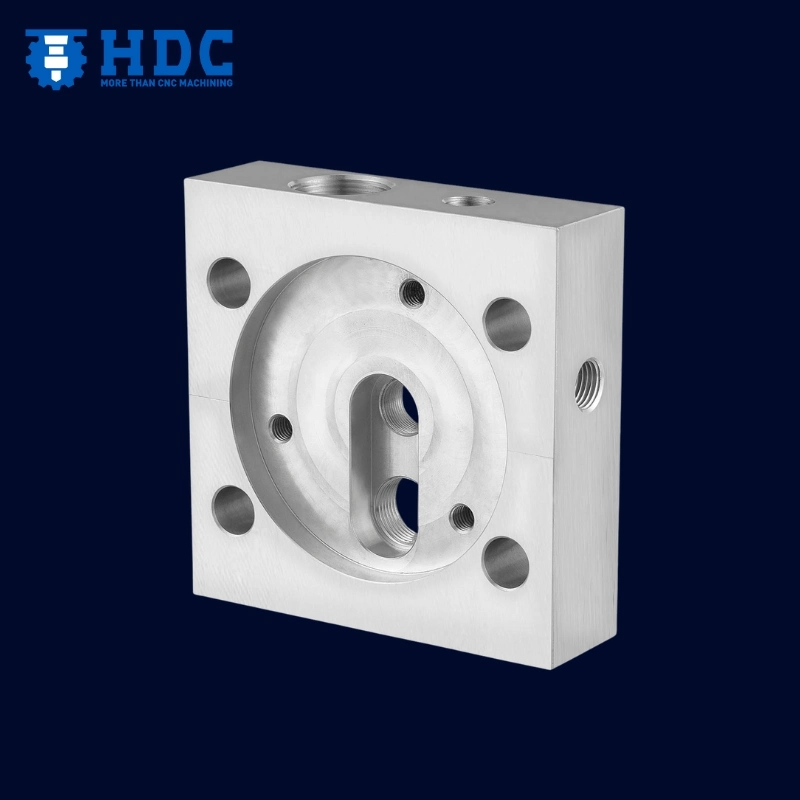

Braking and transmission components are essential for better performance release. In HDC, we use forging for a solid, high-strength fundamental, then implement CNC finishing for critical dimensions and mounting holes.

Ensuring smooth transmission and flexible control at will.

Structural & Mounting

Triple Tree, Body Frame

Structures and mountings require high strength to resist impact and maintain structural completeness and reliability in intense racing.

HDC fulfills all your performance needs by forging with aerospace-grade aluminum, offering top-tier products engineered to give you a competitive edge.

HDC – One-Stop Motorcycle Parts Forging Solution Provider

As a metal fabrication factory that acquires ISO & IATF Certification, HDC provides you one-stop solution for motorcycle parts fabrication.

From DFM, mold manufacturing, prototyping, mass production, heat treatment, CNC finishing, to surface treatment, we handle the whole process with our remarkable in-house machining capability and solid supply chain built with years of effort.

With years of experience in serving the motorsports industry and over 500 customers around the world, HDC understands deeply what you are looking for and what your concerns are. No matter its low-volume modification parts or mass production OEM parts, HDC is here for you with no compromise of quality.

Materials for Forging Motorcycle Parts

HDC can forge over 40 types of metals. Here are the commonly used materials.

Aluminum Alloy

2000 Series

6000 Series

7000 Series

Size & Weight Range

0.1 kg

Min Weight

30 kg

Max Weight

±0.05mm

Tolerance(After Machining)

Ra 1.6 ~ 3.2 μm

Surface Finish

Needs Custom Made Motorcycle Parts?

Our engineers support custom parts for motorsport, dirtbike, and racing builds. Contact us for technical advice or a personalized quote.

FAQ

Do you support low-volume orders?

Yes. Small batch orders are accepted for sampling, after-sales service, or niche market demands. Minimum order quantities depend on the specification—please contact us for details.

What is the customization process?

You send specs or drawings → We confirm details and quote → Sample or batch production → Inspection and shipping.

What’s the typical lead time?

Samples usually take 5–7 days. Bulk orders take around 15–25 days depending on quantity. Custom finishes may require extra time.

How does HDC ensure product quality?

We use aerospace-grade forged aluminum, CNC machining, and strict quality control, including dimension checks, thread inspection, hardness testing, and anodizing thickness verification.

How do you ship orders?

We offer sea freight, air freight, and international courier shipping. Delivery can be arranged to major ports or your specified address.

Do you offer after-sales support?

Yes. We stand behind every order. If you encounter quality issues, incorrect specs, or shipping damage, please contact us—we’ll resolve it promptly.